Every analog-to-digital converter (ADC) or digitizer requires some sort of sampling clock. Electrical transitions on this clock determine when analog signals are digitally sampled and the resulting digital data point is passed to buffer memory.

In many applications, the on-board internal sampling clock provided by the manufacturer is used. In some applications, simple use of an internal clock is not sufficient, and advanced clocking is required.

Advanced Clocking

Advanced clocking is the use of an external clock source or the incorporation of the internal clock source into an external circuit. Figure 1 is a simplified diagram of a basic high-speed digitizer. An analog input signal is routed through signal-conditioning circuitry to an ADC. Upon the rising edge of a clock signal, the ADC samples the analog input signal and holds a measured digital output code over the duration of the clock cycle.

The bit width of the digitized sample is called the resolution and determines the dynamic range of the digitizer. High-speed digitizers are commercially available with maximum sampling rates on the order of 1,000, 100, and 10 MHz for 8-, 12-, and 16-bit resolution, respectively. Digital data codes are stored in a high-speed local memory buffer. The memory address is provided by a counter that is clocked by the same source as the ADC.

An external trigger signal activates storage of the current counter output, which serves as the trigger address. Both pre- and post-trigger data are available in the memory buffer after data capture finishes, usually after a preset number of post-trigger points.

For simple internal clocking, the ADC clock source is derived from a precision internal oscillator. Most commercial high-speed digitizers are equipped with highly stable quartz crystal oscillators, which have nominal accuracies on the order of 100 ppm and temperature coefficients of 20 ppm/°C. This oscillator signal passes through a frequency divider whose output serves as the internal sampling clock source. For example, a typical high-speed digitizer might provide internal sampling rates of 100, 50, 20, 10, 5, 2, and 1 MHz.

Some commercial digitizers have an external input to clock the ADC directly. External clock signals usually must conform to some logic standard—often 0 to 5-V TTL. At rates above 10 MHz, external clock inputs must be terminated to match the impedance of coaxial cables. Termination eliminates reflections in long cables that can lead to false clocking of the digitizer.

External clocking allows sampling at arbitrary rates that are not available as internal sampling rates. Limited internal rate selection usually does not present an obstacle in most applications. Generally, external clocking only is required when some important reference frequency is associated with the experimental setup to which the A/D sampling must be synchronized.

Applications

Imaging array applications most obviously require external clocking, such as digitizing the signal captured from a charge-coupled device (CCD). Within a CCD camera, for instance, CCD array elements accumulate charge in proportion to light exposure. Accumulated charge is transferred to an analog shift register from which analog voltages for each CCD element are serially clocked.

A digitizer that captures this multiplexed signal must be externally clocked by the camera. Internal clocking would lead to sampling of the multiplexed CCD signal during logical transitions. Difficulties also would arise in associating captured samples with their corresponding CCD elements. External clocking ensures that exactly one sample is acquired for each element at the correct time.

Another application that usually requires external clocking is digital down-conversion. With this technique, an RF communications signal is sampled at a rate far below the carrier frequency but still greater than twice the bandwidth of the signal envelope. In this way, the carrier frequency is intentionally aliased to a lower frequency, which can even be DC. External clocking often is required since the sampling frequency usually must be a submultiple of some higher reference frequency—which may be the carrier frequency itself.

A novel advanced clocking technique is nonuniform clocking in which the sampling period varies over time. For instance, an optical encoder produces a logical high and low signal as a photodiode passes over a track of uniform black and white stripes. Each signal cycle represents a uniform travel distance, which is the known stripe spacing. Should the photodiode accelerate, then the period of each pulse will not be constant in time. Consequently, using the photodiode signal as an external clock, a digitizer can be used to sample signals as a function of uniformly distributed distance rather than time.

It is less obvious that advanced clocking is required in such time-domain reflectometry applications as ultrasonics, radar, and laser radar (lidar). Generally, these applications require the capture of signals that result from transmission or reflection of radiation that has interacted with a sample under test. These captured signals may show clearly defined echo pulses from the sample. Signals can occur at an extremely high repetition rate in scanning systems or for samples that evolve in time.

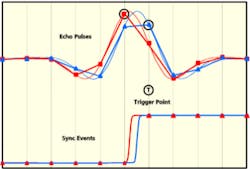

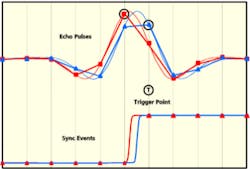

In time-domain reflectometry, advanced clocking can be used to dramatically improve measurements. Figure 2 illustrates the digital capture of a typical echo pulse that might occur in ultrasonics, radar, or lidar.

Usually, a sync signal is available whose rising edge occurs at a specific time relative to the echo pulse. The sync signal, also illustrated in Figure 2 (see below), externally triggers a digitizer.

Figure 2. Asynchronous Capture of Identical Signals

The problem with a digitizer’s internal clock is that it is necessarily asynchronous or unrelated to the external trigger event. Consequently, the trigger event can occur at any time between two rising clock edges and still record the same trigger point.

This situation is shown in Figure 2. Two identical events that occur at different times between the last pre-trigger point and the trigger point are displayed. Although the two echo pulse signals are identical, the captured records are different. This is due to the different time lags between the external sync event and the recording of the trigger point.

Trigger-clock asynchronicity can lead to serious measurement inaccuracies. For example, let us assume that the echo pulses in Figure 2 result from ultrasound that is reflected by a material flaw. Also, assume that experimental conditions such as transducer position and electrical excitation are identical in both cases. The arrival time of the echo signal determines the depth of the flaw within the material. The peak amplitude is an indication of the size of the flaw.

Using simple peak detection, the pulse peak is determined as the highest value in the data pulse. These points are circled in Figure 2. The apparent arrival time and peak amplitude of the two echo pulses are different even though they were produced by the same flaw. The trigger-clock asynchronicity leads to different apparent depth and size.

The most straightforward resolution to the problem is to externally clock the digitizer and provide a trigger signal that always occurs at the same phase of the clock signal. In this case, the jitter on the apparent position is limited only by the temporal stability of the electrical components comprising the digitizer itself. This usually shows a dramatic improvement. For example, for a 100-MS/s asynchronous digitizer, the intrinsic jitter on the peak position will be one sample or 10 ns; however, synchronous triggering and clocking can reduce this jitter to well below 1 ns.

Some digitizers provide a trigger output already synchronized to the digitizer’s clock signal. This is convenient since it is not necessary to provide an external oscillator source.

An added advantage is an improved pulse repetition rate. Using conventional external triggering, the digitizer must await the occurrence of the next trigger. When it acts as the master trigger source, the digitizer can generate a trigger immediately after it has finished handling the previous record. This allows the fastest repetition rate possible for a given digitizer. Finally, since the digitizer issues the trigger itself only when it is ready to do so, there is absolutely no possibility of missing triggers.

Signal averaging is a well-known noise-reduction technique. Multiple records are captured from a source that produces repetitive signals and then are averaged together.

Let us assume that the repeating signal consists of an identical signal of interest with a fluctuating, random-noise component superimposed on it. In this case, signal averaging will have no effect on the signal of interest but will reduce the noise level with each successive average. Elementary statistical analysis shows that, upon averaging, the noise level will decrease by a factor equal to the square root of the number of averages. Using signal averaging, tiny signals can be extracted from a background of high-amplitude incoherent noise.

Care should be taken when signal averaging is used without trigger-clock synchronicity. Asynchronous signal averaging has a smoothing effect on the signal. In fact, taking an infinite number of asynchronous signal averages is equivalent to applying a moving average filter to the signal whose time window width is equal to the sampling interval. This has little effect on a signal whose frequency is low compared to the sampling frequency.

Signal averaging leads to severe attenuation of the signal as its frequency approaches the Nyquist frequency (half of the sampling frequency). Attenuation due to asynchronous averaging rises above 0.1 dB for signal frequencies above 25% of Nyquist.

Synchronous averaging refers to the averaging of signals that are synchronous with the digitizer sampling clock. Since it has no filtering effect on the captured signal, synchronous averaging should be seriously considered over asynchronous averaging for signals containing frequency components above 25% of the Nyquist frequency.

External clocking is absolutely necessary to capture related signals by two or more separate digitizers with long memories. Consider the example where two separate digitizers, each with their own internal sampling clocks, capture the same signal. Assume that the clock sources are quartz crystals with accuracies of 100 ppm. The small difference between the two clock sources has little consequence on the capture of a few thousand points.

However, some commercial digitizers now capture billions of points. If two digitizers with asynchronous clocks capture a billion points of the same signal, then the ends of the resulting records will be misarranged by thousands of points (100 ppm × 1 billion = 100,000). Consequently, separate digitizers always must be externally clocked by the same source if any more than a few thousand points are to be captured.

Figure 3 shows a captured communications signal and its Fourier spectrum. The data record corresponding to the captured signal can be loaded into an arbitrary waveform generator to provide a test signal.

Since the captured signal consists of millions of samples, both the digitizer and generator are clocked by the same 50-MHz clock source. While the generated output signal may be the same as the captured input signal, this need not be the case. Any arbitrary numeric algorithm can numerically condition the captured input signal before generation.

The ensemble consisting of a computer, a digitizer, and a generator can be used as a complex filter element by an external circuit. This element has a signal input and output, imposes a constant time delay on the signal, and filters the signal using an arbitrarily programmable numeric transfer function.

Conclusion

Advanced digitizer clocking can be used in several different applications. Exposure to applications that require advanced clocking gives you a more in-depth understanding of issues that arise in the design of a digitizing system. Armed with this knowledge, you can make informed choices to achieve optimal digitizer performance.

About the Author

Andrew Dawson, Ph.D., is product manager of Board-Level Products and Advanced Measurement Systems at Gage Applied. He received a doctorate in experimental solid-state physics from McGill University in Montreal. Dr. Dawson then worked for three years as a research officer for the Industrial Materials Institute, part of the Canadian National Research Council, and joined the sales and marketing department at Gage in 1997. Gage Applied, a Tektronix subsidiary, 2000 32nd Ave., Lachine, Montreal, QC H8T 3H7, (800) 567-4243, e-mail: [email protected].

Published by EE-Evaluation Engineering

All contents © 2000 Nelson Publishing Inc.

No reprint, distribution, or reuse in any medium is permitted

without the express written consent of the publisher.

July 2000