While long-distance telephone systems have taken advantage of fiber optics for the past 20 years, the recent demand for greater bandwidth in transmitting data has escalated the use and production of this technology. These fiber-optic systems, transmitting data across continents or providing bandwidth for large cities, consist of dozens of components, such as dispersion compensators, collimators, gratings, and attenuators. They are notable for being small and technically sophisticated, with the promise of becoming even more so in the future. The materials that make up these components are not limited to the familiar silicon, but also to the more exotic such as indium phosphide and gallium arsenide.

While size and composition make these components cutting edge, in the manufacturing process, these fiber-optic components still are largely assembled by hand. Traditional labor-intensive technologies cannot keep up with market demands that include high volume and precision manufacturing.

Fiber and Photonics Advantages

Why the buzz over fiber optics? The primary advantage of fiber optics over standard copper transmission lines is the enormous bandwidth that lightwaves provide. The potential information-carrying capacity of any type of medium increases with the frequency of the carrier signal. Optical carrier frequencies are in the order of a few hundred teraherz or about a hundred thousand times that of conventional electrical carrier frequencies.

Other important advantages of fiber optics are weight and size. The fibers typically have diameters not much larger than the width of a human hair.

All of these factors combined to make fiber optics a hot item for both phone and corporate networks, particularly with the growing demand for more bandwidth worldwide. The telecommunications industry alone spends billions of dollars upgrading transmission systems with fiber optics, carrying voice conversations and other data along bursts of light instead of traditional electrical circuits.

Building an Automated System

Creating an automated system that integrates vision, motion, and measurements is critical to meeting productivity demands. With newer measurement, motion, and vision products, manufacturers can use precision stage location and optical feedback in the automation process.

One example of this process is building an automated system using vision-guided motion control to perform gross alignment of a fiber and a lens. Precision is key to a photonics inspection solution. When fiber measurements are rated in the micrometer range, it is imperative that alignment can achieve that level of accuracy.

The camera and inspection algorithms inspect the fiber and perform feedback diagnostics to obtain quality control on the end product. This process ensures that the system spots any defects early in the process.

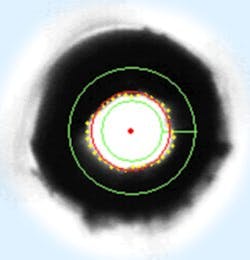

Meanwhile, you can control motion from the same interface where the visual measurements take place. Typical inspection measurements in such a system include fiber core as well as cladding (the outer layer of glass in a fiber-optic cable) diameters, core and cladding noncircularities, and core-cladding concentricity (Do the core and cladding have the same center?).

Building on the PXI™ Platform

Components manufacturing, a subset of fiber-optics manufacturing, is an area where integrated hardware and software can make a big difference in overall production. Emergent Information Technologies (IT), after developing an application for Melles Griot in Boulder, CO, reported 10 times faster assembly times in component manufacturing using a data acquisition system running on a PC-based platform with LabVIEW™ software.

Emergent IT currently is developing a new PXI-based nano-positioning system that integrates motion, vision, and data acquisition technologies. The PXI platform, based on CompactPCI, offers faster triggering time and a smaller footprint, both essential for fiber-optic component manufacturing where productivity, translating into the capability to move and measure fast, is key. First-generation systems often used stage and measurement GPIB devices. These devices parse commands and run sequentially, proving to be slower than PXI.

By choosing a software application best suited to their needs—be it a graphical or text-based language—and integrating it with the most appropriate hardware, manufacturers can further enhance machine assembly productivity with quick development time and the flexibility they need to modify applications. Getting up to speed quickly is important to fiber-optic manufacturers that want to increase low production yields in an industry that still is in its infancy.

A Case Study

LightPath Technologies, a fiber-optic manufacturer in Albuquerque, NM, automated its processes with a system designed in the R&D lab and eventually moved to the production floor. The LightPath system integrates motion, vision, and data acquisition hardware with Lab-Windows™/CVI software, a component of Measurement Studio, running on the PXI platform.

In this application, the system aligns and inspects fiber-optic cable. This crucial process once was performed by humans. As a result of the changeover, the company experienced 10-fold gains in production and development cycles.

LightPath produces collimators that are made from gradium lenses fused to fiber-optic cable and help direct light. The performance and reliability of these intricate parts are integral to the overall performance of telecom systems.

By building multiple systems, the company effectively automated the positioning, fusing, and cutting tasks required in the collimator manufacturing process. With an automated approach, the company gained efficiency, producing more collimators in less time.

The company developed its first systems for lens polishing and fusing several years ago. It still uses the original systems for making tweaks and enhancements to its factory floor system.

As part of the decision to automate, LightPath moved from programmable logic controllers (PLCs) to a PC-based approach. Finding success in its prototype machines, the company decided to duplicate these systems on the production floor. The company initially developed a fusing machine and then used existing technologies to create a laser-polishing machine.

Housed in a clean-room environment, LightPath’s present production floor holds a number of fusing workstations along with space for additional machines. Each PXI chassis contains a variety of hardware, including machine vision, motion control, data acquisition, and GPIB.

The visual results are displayed on two monitors. Meanwhile, a black box houses the motion controllers, cameras, and signal conditioning. This box also contains all the mechanical equipment used in the manufacturing process.

Vision-system components come into play to ensure precise alignment of the fiber-optic cable. The overall system uses three cameras along with two different vision boards. A digital camera and board combination looks at the beam coming out of each collimator, then performs feedback diagnostics to control quality on the end product. This quality check ensures that the system spots any defects up front.

Other CCD cameras look at the angle between each fiber and lens combination, measuring and adjusting the angle to see if it lies within certain tolerances. LightPath has set up process-control parameters for this system, determining what is acceptable and what is not.

On the measurement side, data acquisition boards perform diagnostic tests on the overall system, including measuring encoder feedback, digital I/O for the relays, and other measurements to ensure the process lies within the accepted parameters.

LightPath used the technology it integrated into its initial system for a new, similar polishing system. Using a combination of motion, vision, and data acquisition and based on the same machines used for fusing and alignment on the production floor, the system performs coating and polishing functions on the various lenses before they reach the automated test process.

The company found it easier and more efficient to borrow the technologies already developed for the manufacturing test stations to perform the required polishing tasks. The speed of the polishing system also is dramatic, taking only about 3 s per lens to position, move, and inspect each part. Overall, the system polishes trays with 400 lenses in less than an hour without operator manipulation. This is a significant improvement over previous manual methods.

An Example Application Using IMAQ Vision

Once you have located the cladding boundary using the software’s edge-detection functions, you can calculate the center of the fiber, the circularity, and the diameter. With this information, you can measure the core-cladding concentricity.

To automate the process completely, IMAQ Vision pattern-matching tools can locate the core and then automatically position the region of interest. Standard threshold and blob analysis techniques help locate and count the blemishes within the core.

About the Author

Jason Mulliner currently is a vision marketing engineer at National Instruments. Previously, he worked as an application engineer supporting vision and motion products. Mr. Mulliner received a B.S. in electrical engineering from Brigham Young University. e-mail: [email protected].

Gail Folkins joined National Instruments as marketing editor, served as publications manager, and currently is the vision/motion marcom manager. She holds a B.A. in journalism from Washington State University and an M.A. in English from Southwest Texas State University. e-mail: [email protected].

National Instruments 11500 N. Mopac Expressway, Austin, TX 78759, 800-258-7022.

Return to EE Home Page

Published by EE-Evaluation Engineering

All contents © 2001 Nelson Publishing Inc.

No reprint, distribution, or reuse in any medium is permitted

without the express written consent of the publisher.

February 2001