P waves propagate by compressing material ahead of them and can travel through fluids. S waves create shear forces in materials as they move, so they cannot propagate through fluids.

The distinction between wave types helps explain the complex superposition of reflected and transmitted waves experienced at any particular point affected by a quake. For example, P waves can travel through the earth’s molten core, but S waves cannot, although both wave types are partially reflected by the core. These effects show up as a gap of several minutes between P-wave and S-wave induced motion detected thousands of miles from the focus of an earthquake. Close to the focus, the S waves may arrive only a few seconds after the initial P waves are felt.

Examination of data from the 1994 Northridge, CA, earthquake has correlated motion amplification with S-wave propagation speed and type of soil. Because geology can vary significantly within a small area, there are exceptions to the conclusions.

Generally, less structural damage resulted in hard, rocky areas where S-wave speed was high. More damage usually occurred to structures built on softer soil with correspondingly slower S waves. The so-called amplification factor is the ratio of ground motion of soft soil to a reference motion measured on rocky soil.1

Seismic testing simulates earthquakes to determine if man-made structures can withstand a real quake. Although the actual geological causes of ground motion at any one point are complicated, all earthquakes are characterized by apparently random, large excursions at frequencies below 50 Hz.

Extensive earthquake data is available on the Internet, especially for the many seismic recording stations in California. For example, Figure 1 was plotted from the 1994 Northridge earthquake acceleration time-history data recorded at the Fremont school site, California Division of Mines and Geology (CDMG) station 24461, in Alhambra and processed by Pacific Engineering. Both low-pass filtering at 25 Hz and high-pass at 0.12 Hz were applied to the raw data.2

Seismic Testing

Two popular approaches to seismic testing have developed, and both require special test equipment. Most seismic tests cannot be performed by an electrodynamic shaker because its armature excursion typically is limited to a few inches. Mechanical and pneumatic-hammer shakers cannot be precisely controlled to produce prescribed time-history waveforms. For these reasons, most seismic test equipment is based on electrohydraulic machines.

In addition to providing high-amplitude, low-frequency excitation, these machines must withstand the very large overturning moments that result from shaking top-heavy equipment racks and cabinets. As an example, a horizontal slip table based on Team Corporation’s patented T-Film Hydrostatic Bearings has 300,000 ft-lb pitch and roll capacity.

Sine-Beat Testing

So-called sine-beat testing is intended to excite any resonances that may exist in a structure. Although the motion that an earthquake produces appears to be random, if frequencies are present that correspond to mechanical resonances, damage is likely to occur.

“Most nuclear power-plant and power-distribution equipment tests require a strong motion earthquake for the 30-s duration of the event,” commented Thomas Fischer, manager of ANDI Test Engineering Lab. “It is considered more important [than faithfully simulating a quake] that the seismic motion be uniform throughout the entire event so the equipment can be operated with worst-case input motion.”

Figure 2 shows the normalized standard response spectrum (SRS) suggested by ANSI C37.98 and IEEE 344, IEEE Recommended Practice for Seismic Qualification of Class 1E Equipment for Nuclear Power Generating Stations. The excitation specified in these standards is described as accelerations that would be induced in a set of single-degree-of-freedom (SDOF) mass-spring-damper systems with resonant frequencies from 1 Hz to 40 Hz. The exact level of acceleration will vary according to the severity of the test waveform being applied, and this is accommodated by shifting the SRS profile up or down.

One approach to synthesizing the test spectrum shown in Figure 2 sums harmonic functions spaced 1/6 octave apart. This ensures that excitation exists within the 3-dB points of any possible resonant frequency. By using an iterative procedure, a time history can be developed with a test response spectrum (TRS) that closely matches the desired SRS. Each of the SDOF systems generates a sine wave with a random phase relative to the other SDOF systems.3

In their reference paper, which included an analysis of the 1994 Northridge earthquake data collected at the Santa Monica station, located about 20 miles from the Alhambra station associated with Figure 1, Edward and Thomas Fischer emphasized the importance of acceleration time-history plots as aids to understanding the underlying damage-causing mechanisms. Conventional composite earthquake response plots, similar to power spectrum plots used in vibration testing, display acceleration related to frequency. There is no reference to time. In contrast, time-history plots display the number of cycles of vibration, which is directly related to fatigue stress.4

The natural frequencies of the SDOF systems shown in Figure 3 illustrate the correspondence of the IEEE 344 model to actual earthquake data. In this particular case, time-history plots of SDOF systems also show the quasiresonance phenomena at 4.5 Hz. Rather than the amplitude being nearly constant as it is for the 1.6-Hz and 2.1-Hz SDOF systems, in the Santa Monica area, the 4.5-Hz component of the quake spectrum built up to a potentially damaging 3.8g amplitude.

In the same Fischer and Fischer research paper, reference is made to circuit-breaker failure experienced in the 1971 Sylmar, CA, and 1989 Loma Prieta, CA, earthquakes. “In both examples, it was evident that a resonant type of vibration buildup caused the destruction of these identical 500-kV electrical circuit breakers, which were known to have natural frequencies at about 2.6 Hz. Not only the peak g-level but also the large number of stress cycles would have caused failure according to earlier seismic tests.”

NEBS Testing

The network equipment building systems (NEBS) seismic test is based on the earlier Bellcore GR-63-CORE specifications that relate to telephone equipment racks. Partly because of the recent co-location of local exchange carrier (LEC) equipment with regional Bell operating company (RBOC) equipment and partly because of telecommunications traffic growth, requests for NEBS testing have increased significantly.

Earthquake-prone regions of the United States are grouped into zones 0 through 4 for NEBS test purposes, with zone 4 having the most severe requirements. “Verifying system performance to the specifications of the five national earthquake zones can significantly increase the marketability of a system because it provides the added assurance that it will hold up under the toughest seismic conditions,” commented Steve Little, technical expert at Intertek Testing Services (ITS). “RBOCs in California typically require zone 4 verification for obvious reasons, but zone 4 certification of equipment to be sold in other areas of the country can provide added value.”

The relationship between NEBS testing and nuclear industry seismic testing was explained by Timothy Fey, the manager of environmental testing and the NEBS program at the Southwest Research Institute. “The [NEBS] test method prescribes a special VERTQII waveform, which is an acceleration time history (Figure 4). The waveform was developed by the U.S. Geological Service to envelop the highest-level ground motion predicted to occur in the continental United States, and additional margin has been included to account for multifloor structures. For a test machine to achieve the VERTQII test level, a 10² stroke is required. Most of the VERTQII waveform energy falls below 12 Hz,” he said.

“This approach is quite different from that used in earthquake-prone areas by other industries. For example, in the nuclear industry, motions as described by an SRS are extrapolated to the exact location of the equipment in the facility. IEEE 344 typically is used to guide the development of earthquake simulation for most earthquake testing. It allows for multi-axis testing, which may be a better simulation of true earthquake motion than the sequential single-axis testing specified by NEBS,” Mr. Fey concluded.

In addition to the VERTQII time-history test, equipment is subjected to a 0.2g sine survey from 1 Hz to 50 Hz. Any resonances found must be above 2 Hz, although it is recommended that they should be above 6 Hz.

There also are two other tests in the NEBS suite of vibration tests: office vibration that simulates motion occurring in the normal use of equipment and transport vibration that applies a slowly swept sine excitation up to 500 Hz to prove that the equipment will survive delivery from the manufacturer to the end user.

Test Failures and Design Recommendations

“We often see damaged doors or doors actually coming off of the frames,” noted Mr. Fey. “Cracked welds and bent structural members are typical of poorly designed equipment. Hard-drive failures, dislodged circuit boards, and interconnecting cable-plug pullouts are all routine failures.”

Even if a hard drive doesn’t completely fail, its operation may become unreliable. “Typical operational failures include the failure to pass data packets through the system,” added Michael Hauf, manager of test engineering at Quanta Laboratories. “Data transmission during the office vibration test or seismic event is interrupted or corrupted. Typical physical failures include rack structural-member cracking, cabinet-hinge failures, and screw/bolt/connector failures at their specific shelf or rack locations.”

ITS’s Mr. Little has found latches to be a problem. “Typical failures we’ve witnessed are weak latches and hinges. Sometimes latches may hold up to spec when equipment is shaken in a front-to-back direction, but when it is switched to right to left, the latches come loose.”

Many times, the more spectacular test failures result from cumulative damage. Don Bennett, director of telecom compliance at Garwood Laboratories, said, “If the movement of the frame under test becomes too severe, the welds of the vertical uprights to the base of the frame may crack, weakening the overall structure. At this point, the displacement measured at the top of the frame [relative to the bottom] will become exceedingly large, at times as much as 10² to 12². Another issue has been circuit packs ejecting from the chassis, becoming a potential hazard.”

Some of these mechanical failures are easy to correct. For example, stronger latches attached more securely would solve the problems Mr. Little found. But if the overall structure simply isn’t strong enough, that’s a problem of a different scale.

One way to increase the chances of passing the zone 4 NEBS seismic test is to use a proven enclosure. Phillip Cutler, vice president of engineering at General Devices, described the company’s 7700 Series Vent Rak Cabinet: “It is ideal for applications in danger of exposure to earthquake, severe shock, or vibration. Heavy wall construction, strengthened corner posts, and added longitudinal members with channel sway bracing provide added support and twist resistance.”

Hoffman Enclosures also manufactures telecom equipment cabinets that must pass NEBS zone 4 testing. “We have expanded our engineering test lab to include a seismic table capable of X and Y axis testing,” said Abdi Jama, a design engineer for the company. “This gives us the ability to work with customers to design cabinets that meet their toughest requirements without incorporating the lead times and associated costs of third-party labs.”

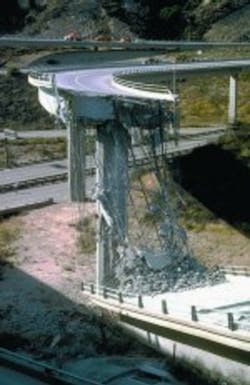

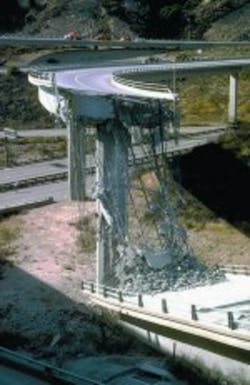

The Fischer and Fischer research paper sums up the relevance of seismic testing and construction techniques: “To mechanical engineers, these [resonant] phenomena can be avoided by insisting upon more rigid structures, at least above a natural frequency of 10 Hz. Otherwise, it might be practical to add special dampers to avoid destructive motion buildup. In general, there is a need for more microzonation studies to indicate local damage potential. The reader is left to imagine the various buildings, highway structures, and electrical equipment that could be damaged if they happened to be tuned to an excitation frequency present in an earthquake.”

References

- USGS Response to an Urban Earthquake—Northridge ’94: The Local Effects of Strong Ground Shaking, greenwood.cr.usgs.gov/pub/open-file-reports/ofr-96-0263/localeff.htm

- peer.berkeley.edu/smcat/data/ath/NORTHR/ALH-UP.AT2

- An Implementation of the ANSI Standard C37.98, The Swedish National Testing and Research Institute, www.sp.se/mechanics/svenska/Hallfasthet/vibrationer/AnsiC37.98.pdf

- Fischer, E. G. and Fischer, T. P., “Quasi-resonance effects observed in the 1994 Northridge earthquake, and others,” Shock and Vibration, Vol. 5, 1998, pp. 153-158.

Acknowledgements

These companies provided material for this article:

- ANDI Test Engineering Laboratories

- Garwood Laboratories

- General Devices

- Hoffman

- Intertek Testing Services

- Quanta Laboratories

- Southwest Research Institute

- Team Corporation

For More Information

Selected Websites on Earthquake Data

www.rsleads.com/208ee-176

Earthquake Facts From Caltech

www.rsleads.com/208ee-177

Return to EE Home Page

Published by EE-Evaluation Engineering

All contents © 2002 Nelson Publishing Inc.

No reprint, distribution, or reuse in any medium is permitted

without the express written consent of the publisher.

August 2002