Find out how PC-based test can play a major role in the quality of the food we eat.

Providing the industry with knowledge-intensive solutions that address unmet needs is a major focus of E. I. DuPont Canada. So it was no surprise three years ago when DuPont�s Agriculture & Nutrition Platform presented its partners with a new test challenge: find an objective way to assess grain quality as it relates to diseases and handling conditions.

Testing the attributes of grain, the result of man collaborating with Mother Nature, is different in many ways than testing a standard electronic product. With that as the premise, a new frontier for PC-based test solutions has emerged.

In a nutshell, DuPont�s vision was to create an advanced image analysis system that assesses grain quality for specific visual factors in a consistent, rapid, and accurate manner. Branded DuPont Acurum�, the new solution, anticipated to ultimately affect more than 500 million tonnes of wheat, automates a previously manual inspection process and is available to all stakeholders in the grain supply chain including farmers, handlers, export terminal operators, and export grain customers.

Grainy Facts and FiguresCertain diseases that develop in grain are not easy to see. Even worse, severely diseased grain could unknowingly pass into the food chain.

The strategy for constructing a solution began to take shape in June 2002. DuPont signed a series of strategic development alliances, followed by designing the actual test instrument, creating the shell, determining the testing process for the system itself, and finally launching the Acurum system.

Step 1. Partnering for Success

DuPont wanted an objective test platform to inspect and analyze grain in an unbiased and impartial method. The results of this collaboration are expected to become a routine and commonplace test process not only in North America, but also in Australia and other parts of the world.

The challenges of testing grain brought together four previously unrelated companies: CIMTEK, Agriculture and Agri-Food Canada (AAFC), Neural Ware, and Linnet to augment DuPont�s internal expertise. The starting point was a global license from AAFC to commercialize its seed-imaging neural-network technology.

Artificial neural networks (ANNs) are computational systems with architecture and operation based on knowledge about the biological neural cells (neurons) in humans. ANNs, like people, have the capability to learn by example.

An ANN is configured for a specific application, such as data prediction or data classification, through a learning process. So with the aid of ANN technology, a highly objective grain assessment model was achieved.

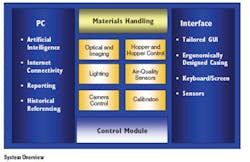

CIMTEK, a custom test systems and services company, designed, constructed, and integrated the solution. Other partners contributed to the database, software, and artificial intelligence (AI) development. AAFC provided its knowledge of the agriculture sector and experience using AI software and imaging systems.

Step 2. Strategy for a Solution

Numerous factors affect grain quality and, as with anything in nature, they continually are changing, requiring the solution to be dynamic as well. The system must identify criteria used to determine grain quality. Through certain visually observable attributes, diseased seeds, improper harvesting (dirt, split kernels), improper storage conditions (mold, bin-burnt kernels), weed-seed contamination, cross contamination, and environmental factors (frost, drought) can be identified. All of these potential conditions have a significant effect on the quality and safety of grain in the food chain.

With its roots in research conducted by AAFC scientists, the new test solution would rely on neural network-based AI. Each instrument would be part of a larger globally deployable network ensuring that, as field conditions change, new capabilities could be updated instantaneously via the Internet, preventing the machine from being outdated and expanding its capabilities and value in the food chain.

Step 3. Creating the Shell

DuPont and CIMTEK created the shell of the solution, a machine vision system capable of imaging grain in a rapid, repeatable, accurate, and consistent manner. The advent of cost-effective, high-speed cameras and the ever-increasing availability of computing power made possible what only a few years before was deemed commercially unviable. However, pulling together these technologies included several challenges and resulted in a system comprising several specialized components.

A Grain of a Different Color

The color characteristics of the imaged sample would have to be rendered accurately and repeatably, not only from one test to the next, but also from machine to machine. For the level of color consistency required, a reliable process including dynamic and automatic color-correction algorithms was devised. This process relied on a gray card for flat-field correction and a high-quality color chart for creating color profiles and verification.

A color-correction algorithm also was developed. The solution produced accurate machine calibration that compensated for system-component degradation, variability, and environmental conditions.

Another challenge was the level of light intensity and color evenness of the lighting system. Lighting systems within the appropriate pricing range were inadequate and needed to be developed.

Custom-Made

A unique challenge related to the nature of a seed sample to be tested, the number of seeds in each sample, and the time required to test each sample. When run through the testing chute, the seed sample exhibited both fluid and particle characteristics. This meant that current particle-handling systems were not fast enough to test a sample of grain in an acceptable amount of time. Since they required highly regular shaped particles, the commercially offered systems would not work.

CIMTEK responded with a new material-handling design and has applied for a patent. The system consists of a metering hopper that expels an appropriate amount of seeds onto a belt that conveys the seeds past the machine vision system.

Many considerations were unique for handling grain. The imaging system had to address color, sheen, profile, and static electricity issues. Extensive research was done to avoid intersample cross-contamination and seed containment of different grain samples.

The system was designed to minimize the possibility of cross-contamination and, after several design iterations and extensive, time-consuming testing, it proved successful. Special six-sigma tests of the Acurum system itself were run to ensure no cross-contamination under specified conditions.

The image processing necessitated a custom software solution because no off-the-shelf package has the breadth of parameters, speed, and flexibility required to correctly handle image processing. The multiplicity of conditions requiring detection proved to be one of CIMTEK�s biggest challenges.

Two of these conditions are diseases called ergot and blackpoint. Grain that contains ergot is very black in color and can be very harmful if ingested. Blackpoint seeds are identified by blackened areas on the ends of a seed and significantly lower the grade of a wheat sample.

The individual seeds contained in each frame are extracted from the background and processed to obtain color, spatial, and textural information. They also pass through a series of validation algorithms to qualify that the measured particle is indeed a seed and not some other type of particle present in the sample.

To accomplish this, a series of underlying structures that represent a seed�s shape and color is determined. Image planes that contain the pixel-by-pixel values of the red, green, blue, and gray components of the seed are calculated.

The seed�s outline also is broken into a two-dimensional hierarchy of perimeter points and a special type of descriptor model named a Freeman Code. From these and other image-processing structures, numerous algorithms are applied to obtain the parameter solution.

More than 300 parameters describe key characteristics of a seed. Some of the shape descriptors such as roughness and asymmetry are based on the Fourier transforms of a seed�s perimeter. Textural identifiers such as contrast and entropy use pixel spatial derivatives; color parameters such as skewness and kurtosis are statistical measures calculated from seed RGB color histograms.

The parameter solution consists of the results of many standard and custom image-processing algorithms. These parameters are passed on to the ANN during its learning phase.

A successful classification model then is generated to identify various grain characteristics. For certain types of characteristics such as blackpoint, custom algorithms generate parameters that could identify a specific problem.

After these challenges were overcome, the system capable of imaging thousands of grain particles repeatably, accurately, and consistently in about two minutes took shape. The AI was integrated, and the system was ready for testing.

Step 4. Testing the Tester

Naturally, out in the field, these machines need to last a long time. As a result, every detail was examined; even the angles on the machines were designed so a coffee cup could not be placed on it, preventing accidental spills. To ensure high reliability, life testing of internal components and temperature/humidity testing were undertaken as a normal process.

Certification

The unit�s worldwide market potential required safety and EMI/EMC certification. Safety-certification and EMI/EMC testing were conducted at regulatory facilities, and the design and implementation have met the certification status of Canadian Standards Association (CSA) with the adjacent indicators C and US meeting CAN/CSA-C22.2 No. 1010.1-92, CAN/CSA-C22.2 No. 1010.1B-97, or ANSI/ISA 82.02.01 1999.

EMI/EMC approvals include FCC Part 15 Class B; ICES 003, Issue 3, Class B (CAN/CSA CISPR 22-96); and EN 61326:1997 +A2:2001. With the help of a third-party test organization such as CSA, the CE mark was issued.

Step 5. Product Launch

After initial setup and calibration, the tester is ready for use. The operator pours a 10,000-seed sample of grain from a shipment into the hopper at the top of the Acurum.

There is no need for alignment or special handling of the seeds. The control module ensures that the camera, lighting, and hopper control are working and synchronized. When the grain is poured, a digital image is taken of each seed, and image-processing software calculates more than 300 color, size, shape, and texture parameters for each kernel. With 10,000 seeds, this generates a massive database, which then is analyzed in the PC by the pretrained neural network software. Within minutes, the results are available, and the final quality specification of the load can be determined.

A global connectivity system allows each instrument to call home on a predetermined schedule to download the test results. This system lets the users operate at full speed, without being online. Through periodic connections to the Internet, the operator receives the most recent updates. The test results are kept in a secure server, and the operators can consult the data when required.

Conclusion

Although still in field testing, there will be hundreds of Acurum instruments in various stages of deployment over the next year. CIMTEK and DuPont continue to work with the partners to enhance the deployed systems. And since CIMTEK announced its strategic development alliance with DuPont Canada in 2003, it is entering into discussions with other global agriculture authorities.

About the Authors

Ward Metzler is a chemical engineer who has been with DuPont for 25 years with experience in manufacturing, R&D, and business development. He is the Acurum venture manager based in Mississauga, Ontario. E. I. DuPont Canada, 7070 Mississauga Rd., Mississauga, Ont L5M 2H3, 905-821-5706, e-mail: [email protected]

James F. Egan, P.Eng., is the chief technology officer, vice president of strategic business development, and cofounder of CIMTEK. He holds a degree in electrical engineering and computer science from the University of Waterloo and currently is a member of the Association of Professional Engineers of Ontario and the Institute for Electrical and Electronics Engineers. CIMTEK, 5328 John Lucas Dr., Burlington, Canada L7L 6A6, 905-331-6338, e-mail: [email protected]

FOR MORE INFORMATION

on strategic development alliances

www.rsleads.com/408ee-255

August 2004