As real estate shrinks, today's boards have more capabilities but far less ESD protection.

Sensitivity levels to ESD in electronic devices will drop so low over the next five to 10 years, according to the ESD Association, that manufacturers must act quickly and deliberately to ensure their ESD control programs can handle the new levels. Failure to understand and develop controls for the lower sensitivity levels could be disastrous.

OEMs could see declining yields as in-house tests reveal more defects and warranty returns increase. Contract manufacturers could lose business and be forced to shut down assembly lines if they cannot determine and prove their processes are capable of controlling ESD down to a specified level.

ESD Technology Roadmap

The ESD Association, a leading authority on static control since its formation in 1982, recently began tracking sensitivity levels and obtained projected sensitivity limits through 2010 from engineers at IBM, Texas Instruments, and Intel. The association published a summary of the trends in the ESD Technology Roadmap in March 2005.

As the roadmap indicates, the electronics industry first recognized ESD as a problem in the late 1970s. By the early 1990s, as a result of device improvements and process controls, a comfortable difference existed between the known sensitivity limits and the ESD-control capabilities of manufacturing processes.

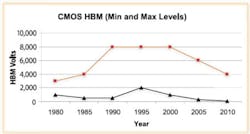

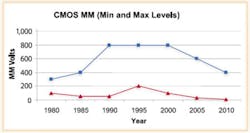

By 2005, however, sensitivity limits had shifted downward, and the gap had begun to close. Over the next five years, it will continue to tighten. Figure 1 and Figure 2 illustrate the range in sensitivity levels for the majority of CMOS devices between 1980 and 2010.

For years, the semiconductor industry has been warning about ESD as a growing menace. It has cited trends and design challenges in its own roadmap, the International Technology Roadmap for Semiconductors, which is updated annually.

Why the Increasing Sensitivity?

Over the past two decades, electronic devices have shrunk in size, and semiconductor features have grown increasingly dense. As PCBs become more densely populated and semiconductor technology shrinks in size, they are more vulnerable to miniscule ESD events.

Sensitivity limits of 100 V and lower have existed at least since the 1980s but only in a small proportion of devices and markets. Typically, extremely sensitive devices are made by specialty manufacturers using stringent static-control programs.

A case in point is the magneto-resistive (MR) head used in hard disk drives. It was introduced in the mid-1990s, causing manufacturers to deal with ESD sensitivity levels that had plunged from 1,000 V to less than 20 V seemingly overnight.

More recently, designers have faced the continuing challenge of cramming more functions into smaller chip territory. The chip on an RF identification tag, for example, is smaller than a grain of sand, yet it contains all the functions that a chip four times its size had two years ago. As real estate is given up, ESD protection networks come off. The trade-off is greater risk for ESD damage.

Equally significant, designers have run into physical barriers they can t design around. Photo-imaging technology, for example, has just about reached its limits. The lines in wafer patterns now are only 90 nm wide and expected to diminish to 45 nm or next to nothingness.

RF applications are particularly prone to damage from even the smallest static charge because of the sensitive nature of their semiconductor material: gallium arsenide (GaAs) or silicon germanium (SiGe). Today an estimated 30% of cell phones that die can blame ESD as the cause.

Design and new technology may help overcome these barriers. Electronic Polymers, a new company in Round Rock, TX, offers a new generation of polymerized material that can be built into a chip and protect against ESD by shunting it to ground in nanoseconds before it can inflict damage.

In the meantime, manufacturers must deal with the ultra-sensitive devices showing up more frequently in production lines. Volumes will increase through 2007 and 2008 as these sensitive devices spread into large consumer markets. Anyone who wants a piece of the action must demonstrate a mastery of ESD control.

Responding to the Challenge

If manufacturers doubt what mastery of their ESD control must look like, the roadmap spells it out:

• Determine the ESD-control capabilities of your factory's handling processes.

• Design personnel grounding systems to limit body voltage to less than 100 V.

• Make sure all conductive fixtures or tooling that contact sensitive devices are grounded.

• Ensure that maximum voltage induced on devices is kept below 50 V.

The industry already has a good resource for addressing these directives. ANSI/ESD S20.20, issued by the ESD Association in 1999, was intended to bring uniformity to multiple stand-ards that previously had been applied piecemeal from company to company. It was written for programs handling 100-V human body modeling (HBM) or higher, but in reality, S20.20 can be used in any ESD control program with slight modifications.

Determining ESD Capabilities

S20.20 is particularly useful for determining the ESD-control capabilities of handling processes. It requires program managers to know the sensitivity levels of the components being assembled and identify ESD issues at each stage in the process, from receiving and inventory through kitting, assembly, test, rework, and shipping.

Managers must assess the possibility of static discharge from personnel, machines, and the environment; formulate plans for controlling it; and evaluate control at every stage. In short, they need to understand how it all comes together and articulate capabilities by voltage level.

Personnel Grounding Systems

Procedures for grounding personnel who handle ESD-sensitive devices are well defined. With proper equipment and training, workers can keep body voltages below the prescribed levels.

S20.20 suggests that seated workers be grounded by wriststraps at their workstations. Wriststraps can be evaluated either by periodic manual testing or with constant monitors that emit alarms if grounding is lost. Some monitors automatically log data on grounding and ESD events. Such documentation can be used as evidence of control during audits by independent certification agencies.

Mobile workers may be grounded through a flooring/footwear system. Because of body movement and the resulting difficulty in predicting body voltage, process capability can be determined through the use of the test described in ESD STM 97.2.

Personnel grounding is one area in S20.20 that requires modification to handle ultra-sensitive devices. Currently, S20.20 recommends setting resistance to ground in wriststrap and flooring/footwear systems at 35 MΩ, which translates to 100-V HBM. To handle products with sensitivity lower than 100 V, resistance to ground also must be lower. For products with sensitivities of 50 V, for example, the resistance to ground in a wriststrap should be set to below 20 MΩ.

Although personnel grounding is straightforward, many manufacturers don't fully understand it. For example, one company invested in a first-rate static-protective floor but chose low-cost ESD-protective footwear. When tested, the voltage on these people was in the 300-V range. The company thought it could buy any product and get down to 100 V. If the company had understood the relationship and evaluated the system properly, the error could have been avoided.

But even the best control equipmentin the world can be ineffective if employees are not properly trained. Training often is overlooked or poorly executed. It's perhaps the most common problem that turns up in S20.20 audits.

Workers not only need training when they re hired, but also every year or so to keep them up to date on changing sensitivities. And S20.20 requires that training be documented.

Some training programs on the market test individual workers and document test scores. Many companies, including 3M, offer static awareness seminars, plant audits, and employee training to ensure the effectiveness of the total static-control solution.

Grounding All Conductive Elements

Grounding is an S20.20 requirement. Essentially, it refers to all of the conductive fixtures and tools typically installed on automated equipment that come into contact with sensitive products on the assembly line. In this case, suppliers build in the grounding as part of the machine.

ESD program managers need to take periodic measurements to ensure that moving parts remain grounded throughout the process. ESD control embedded into machinery is essential but problematic. Of all aspects of a static-control program, this is the where the holes are.

Controlling static inside the machine is critical. Tools now are being developed that can analyze automated equipment. Work also is underway on data-recording devices that track what they see inside machines. Predicting the outcome is premature, but solutions will be important in protecting ultra-sensitive products down the road.

Keeping Induced Voltage Low

The fourth roadmap directive, keeping induced voltage below 50 V, refers to the electrical fields that can occur when a charged item is brought into close proximity to a sensitive device. Static charge can be generated by insulating materials such as plastics at any point in the handling process.

Often, control is achieved by simply prohibiting the presence of these materials, such as polystyrene coffee cups, on the factory floor. You also can implement controls to assure that process-relevant insulative materials are kept at a safe distance from sensitive devices.

In many cases, however, insulating materials cannot be removed. One solution is to bathe the area with ionized air to neutralize the static charge.

Large ionizers can be mounted overhead to cover approximately four feet of the assembly line, and smaller ionizers placed on the worksurface or inside equipment can neutralize smaller areas. A hand-held gun ionizer aimed directly at a sensitive item is a particularly useful way to blow off particulates without generating static.

Where to Start

Manufacturers certified to S20.20 already have done much of the work in addressing the roadmap's directives. But they need to stay on top of the game. Watch the sensitivity levels of components and, at each annual S20.20 audit, be able to articulate what has changed and how you re responding.

Other manufacturers need to make ESD control a top priority. The first step is to get some education. Learn how the various ESD control elements work and how to plan a comprehensive program.

Workshops are available from the ESD Association. In addition, the association has started a new professional certification program for ESD control program managers that requires completing seminars and tutorials, passing an exam, and participating in continuing education.

Upper management must be committed to the roadmap. In many companies, ESD control might become a team assignment as in a Six Sigma• Black Belt program.

Once you have a plan that addresses the roadmap, let a third-party auditor check it out. An auditor can identify weaknesses in your processes and help you maintain the proper documentation.

A Wake-Up Call

The ESD Technology Roadmap is a kick in the pants for the entire industry. Fortunately, many companies have started paying attention. The ESD Association reports fairly heavy downloading of the roadmap from its website. At the association's September 2005 symposium in Anaheim, the opening speaker focused much of his presentation on the roadmap and its implications for the industry.

People had better get ready. The question is: Will they get there fast enough?

About the Author

Curtis Maynes is technical manager for the 3M Static Control and Transport Solutions businesses. He joined 3M in 1993 after earning a bachelor's degree in electrical engineering from the University of Notre Dame. Mr. Maynes later worked in the 3M static control business as a technical service/product development engineer and, from 2001 to 2003, was a charter member of the company's new Six Sigma Black Belt program for process and quality improvement. 3M Electronics, Electronic Solutions Division, 6801 River Place Blvd., Austin, TX 78726, 512-984-4073, e-mail: [email protected]

FOR MORE INFORMATION

on the ESD Technology Roadmap

www.rsleads.com/602ee-178

on the International Technology

Roadmap for Semiconductors

www.rsleads.com/602ee-179