Powering ATE is a dirty job, and don�t let anyone tell you to ignore it.

You�ve just won a program to replace an older weapons system with the latest upgrades. But when it comes to support, you find marketing plans to update only the ATE�s programmable supplies, computer, and instrumentation. The older system had linear power supplies and data acquisition rates that really are in the cellar.

New processors, programmable switching supplies, and high-speed Ethernet controls will save you a bundle on throughput. But what will they do to noise susceptibility?

Starting with a foundation of properly conditioned power will eliminate the phantom failures that haunt most new projects. Providing the appropriate conditioning, along with proper grounding, will effectively mitigate a future breakdown of system components and shelter you from those beyond-your-control environmental hazards that occur long after the system has been installed.

Present-day electronic systems and components are far more sensitive to noise than their predecessors. To begin with, switching logic levels are down around 3 V on most of the new semiconductors, and it doesn�t take much to mistake a stray harmonic for a timing pulse.

The vulnerability problem becomes more complex when you consider higher data rates and DAC resolutions that have moved from 12 b to 20 b. High-speed microprocessors manage PID loops with update rates that are multiples of those used in the 1990s, and the high-speed switching circuits used in programmable DC and AC supplies create nonlinear loading on your power bus at frequencies that were never considered during the original ATE design.

These elements come together in ways that may bypass or even resonate with your old power conditioners, making the test system even more susceptible to electrical noise and transients. Noise and transients can trigger semiconductor switching at the wrong time, interrupt digital clock timing or sequencing, or cause errors in your acquired data. Best case, these things are merely disruptive. Worst case, they are destructive.

Operating environments also are changing. ATE systems must frequently be transportable, so weight is a major issue. Shelter-mounted systems like clean-room systems are starved for space.

In many combat or Third World operations, your only power sources come from Vietnam era gen-sets or local power of questionable quality. The

208-V three-phase power often looks more like 200 V, and the 60-cycle generator you were promised turns out to be 50 Hz from the British battalion across the field. What�s worse, about the time you run your lines across the ground to your test site, some high powered transmitter turns on, radiating every inch of the power lines each time it sweeps.

Facilities for ATE support everything from PCBs to jet-engine test cells. In today�s world, more and more of them are being remotely located, and stability of the power source often is an afterthought.

What are the symptoms? Phantom failures. You chase them from instrument to controller and back again, replacing boards in your VXI chassis, switching power supplies, and rewiring the backplane only to find the problem resurfaces on another run.

System errors may become prevalent on your monitor. Warning signs, like discolored capacitors or melted insulation on a neutral leg, point strongly toward common-mode noise and high-impedance returns. Over time, you notice unexpected performance degradation, a sure sign of transient problems, and likely the loss of what transient voltage surge suppression (TVSS) protection you may have had, a fault that generally is transparent to the system users.

The Problems

Where do power problems originate? Problems addressed by conditioners consist primarily of transients in the form of ring pulses or unidirectional transients, harmonics, filter resonance, high-impedance grounding, and brownouts. There are four sources of the noise:

� Noise generated from the power lines as they distribute power to your facility.

� Noise generated by your neighbors on the power grid, be they down the street or in the next room.

� Load-side noises generated by test equipment within your system or even the units under test and then fed back across the ATE power bus or ground to the controller and displays that orchestrate your test program sets.

� The connections intended to provide clean, low-impedance power; the grounds; and neutral returns can create problems that relate to wiring practices as well as proximity of the power conditioner to what it is protecting.

Here are just a few types of power-related problems that can occur in your application along with some commonly applied solutions:

� High-Frequency Electrical Noise�typically addressed with low-pass filters and clean grounding

� Spikes and Transients�typically addressed with low-pass filters, TVSS, and clean grounding

� Voltage Fluctuations�typically addressed with voltage regulation and uninterruptible power supplies (UPS)

� Incorrect Line Voltage�typically addressed with step-up or step-down transformers or voltage regulation

� AC Line Sags and Swells�typically addressed with voltage regulation and UPS

� Generally Unstable Power�typically addressed with filtering, suppression, transformers, isolation, clean grounding, voltage regulation, and UPS

Managing these power problems is critical. You must know enough about the issues presented by every new piece of hardware in your system to provide your specific power subsystem with the right mix of solutions.

Source Saboteurs

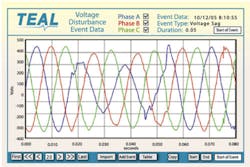

Line-side noise generators like lightning strikes, peak loading due to regional air-conditioning demands, and power-factor capacitor bank switching are examples of sources of electrical noise on the line that can infiltrate your sensitive electronics. Figure 1a shows severe voltage sags. Even if your regional electric utility guarantees a level of power quality, it often has no control over these transient issues.

Noisy Neighbors

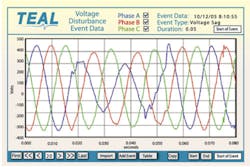

Noise generated by co-users of incoming power can be frustrating because of the social and technical problems it raises. The printing press next door, the elevators in your building, the welders in the shop out back are examples of sources of electrical noise that may come from co-users of your incoming power lines, and they can all affect your sensitive electronic systems (Figure 1b).

Productive Polluters

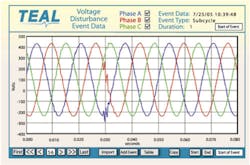

Productive polluters are noise sources found within the ATE systems and their test loads. Switching power supplies, high-speed microprocessors, and high-power test equipment are examples of sources of electrical noise that may be generated by the equipment you are using to excite your test object and measure its performance.

Although you have some control over these systems, you still must deal with the disruptive and potentially damaging effects of the noise they create. Even if you use a dual-conversion, online UPS to eliminate all of the line-side noise, you have to live with these load-side perturbations (Figure 1c).

Since you cannot completely eliminate the source of these noises, the only choice you have is to reduce them to the point that they are no longer troublesome.

A Clean Sweep

Modern power conditioning and distribution units (PCDUs) can mitigate your power problems with a single-box solution. All you do is connect the power you�re dealt to the input and plug in the ATE.

The modern PCDU can contain one or more of the following power solutions in a single package:

� Isolation transformers provide line-to-load isolation; a clean, single-point ground; and common-mode noise rejection and often include voltage conversion and world input voltage capability.

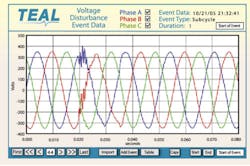

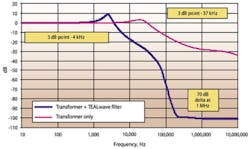

� Fast-response low-pass filters improve power quality by reducing electrical noise spikes and transients (Figure 2).

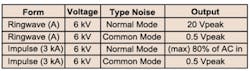

� TVSS reduces large voltage spikes to a safer level. Table 1 lists transient suppression performance.

What�s New

The advent of tougher agency controls, concerns about product liability, demand for higher resolution, international applications, and the move toward distributed DC programmable power have driven the power conditioner manufacturers to offer many new options. Some of them enhance performance, and others provide new levels of customer service and product support: remote Ethernet monitors, redundant TVSS, regulated AC, low-impedance transformers, and pulse power accommodation just to name a few.

Many of these new features are designed to improve overall system reliability and uptime and assist in overall system diagnosis if problems do occur. Even though AC power is a mature industry, modern technology improvements can be tapped to improve your overall power quality and reduce the impact of an otherwise dirty power source. Starting with a known clean power line will shorten your development time, minimize your customer support costs, and add to the overall success of your program.

About the Author

Robert Close is the military aerospace product manager at Teal Electronics. He has spent 30 years in the military and aerospace power and controls market where he has worked in engineering, quality, sales, and marketing. Teal Electronics, 10350 Sorento Valley Rd., San Diego, CA 92121, 858-558-9000, e-mail: [email protected]

FOR MORE INFORMATION

on power-quality scenarios

www.rsleads.com/605ee-178

May 2006