imec extends damascene metallization towards the 3-nm technology node

Leuven, Belgium. At this week’s 2018 IEEE International Interconnect Technology Conference (IITC 2018), imec is presenting 11 papers on advanced interconnects, ranging from extending Cu and Co damascene metallization all the way to evaluating new alternatives such as Ru and graphene. After careful evaluation of the resistance and reliability behavior, imec is taking the first steps towards extending conventional metallization into to the 3-nm technology node.

For almost two decades, Cu-based dual damascene has been the workhorse industrial process flow for building reliable interconnects. But when downscaling logic device technology towards the 5-nm and 3-nm technology nodes, meeting resistance and reliability requirements for the tightly pitched Cu lines has become increasingly challenging. The industry is, however, in favor of extending the current damascene technology as long as possible, and therefore, different solutions have emerged.

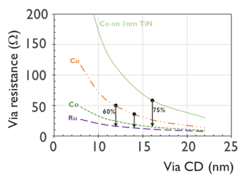

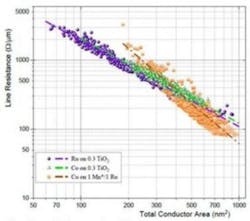

To set the limits of scaling, imec has benchmarked the resistance of Cu with respect to Co and Ru in a damascene vehicle with scaled dimensions, demonstrating that Cu still outperforms Co for wire cross sections down to 300 nm2 (or linewidths of 12 nm), which corresponds to the 3-nm technology node. To meet reliability requirements, one option is to use Cu in combination with thin diffusion barriers such as tantalum nitride (TaN)) and liners such as Co or Ru. It was found that the TaN diffusion barrier can be scaled to below 2nm while maintaining excellent Cu diffusion barrier properties.

For Cu linewidths down to 15 or 12 nm, imec also modeled the impact of the interconnect line-edge roughness on the system-level performance. Line-edge roughness is caused by the lithographic and patterning steps of interconnect wires, resulting in small variations in wire width and spacing. At small pitches, these can affect the Cu interconnect resistance and variability. Although there is a significant impact of line-edge roughness on the resistance distribution for short Cu wires, the effect largely averages out at the system level.

An alternative solution to extend the traditional damascene flow is replacing Cu by Co. Today Co requires a diffusion barrier—an option that recently gained industrial acceptance. A next possible step is to enable barrierless Co or at least sub-nm barrier thickness with careful interface engineering. Co has the clear advantage of having a lower resistance for smaller wire cross-sections and smaller vias. Based on electromigration and thermal storage experiments, imec presents a detailed study of the mechanisms that impact Co via reliability, showing the abscence of voids in barrierless Co vias, demonstrating a better scalability of Co towards smaller nodes.

The research is performed in cooperation with imec’s key nano interconnect program partners including GlobalFoundries, Huawei, Intel, Micron, Qualcomm, Samsung, SK Hynix, SanDisk/Western Digital, Sony Semiconductor Solutions, Toshiba Memory, and TSMC.