Download this article in PDF format.

As a part of the Industry 4.0 movement, factory engineers are increasingly adopting some form of industrial Ethernet to interconnect the machines and other equipment implementing their production processes. Ethernet has been around in multiple forms for over 40 years. Most of it serves the IT community by interconnecting PCs and other equipment to a company LAN.

Because of its flexibility, Ethernet has been adapted to many industrial uses. There’s even an automotive version. Industrial Ethernet is gradually replacing fieldbuses and other networking schemes. That being the case, how does one select and enable an industrial Ethernet standard and embed it in factory machines and computers?

Sponsored Resources:

- Multiple industrial communications protocols for different system types

- TSN - Time-sensitive networking for industrial automation

- Running industrial protocols on PRU

Industrial Ethernet

Industrial Ethernet is a variation of standard Ethernet that has been adapted to factory automation and process control applications. It’s a flexible networking solution for interconnecting PLCs, machine tools, robots, drives, sensors, and actuators. However, be aware of two main issues when using standard IEEE 802.3 Ethernet.

First, the network wiring needs to be much more robust than office-grade wiring. It’s still twisted pair, but better protected. The harsh industrial environment requires heavier-duty cables and stronger connectors. Industrial-grade Cat5 and Cat6 cables are available, as are several different types of connectors.

The data is sent half-duplex with a speed of 10 Mb/s, 100 Mb/s, or 1 Gb/s. Most systems use 100 Mb/s. Multiple network topologies are possible, including bus, star, and some special combinations including a ring. All of these flexible qualities make industrial Ethernet a top choice for a wide range of industrial systems.

The second major issue in adapting Ethernet to the factory is timing. Many if not most of industrial applications require determinism—a guaranteed time of arrival and execution of a command or data delivery. Protocols like TCP/IP, which are widely used on top of Ethernet, do provide a guaranteed delivery, but not the timing so important to industrial applications. Industrial functions need real-time transmission and reception to ensure that a particular operation is performed at the time required (see “Time-Sensitve Networking (TSN)” at the end of the article).

To achieve the deterministic functionality on an Ethernet platform, you need to use one of several industrial Ethernet protocols. Production systems in a modern factory are usually connected using real-time Ethernet. A time-sensitive protocol is the key feature of a network that connects various control systems in real time. The most popular protocols to ensure this are EtherCAT, EtherNet/IP, PROFINET, POWERLINK, and SERCOS III. All are enhancements to the standard Ethernet protocol to ensure determinism. Choosing one and implementing it is a challenge.

Selecting the Right Industrial Ethernet Standard

Over 20 different industrial Ethernet protocols are available, and no doubt one of these will fit your situation. Many are vendor-specific. But there are some more popular and widely used protocols like those mentioned above. Each uses a different method to implement the determinism function. A major concern is that different industrial products use different protocols. How do you connect them so that they can communicate with one another?

Obviously, one good solution is to acquire products using only the protocol you select. However, that may not be possible. But if you stick with one the more popular protocols named above, you can find some workarounds to facilitate interoperability.

If you’re designing a product for factory automation, you want it to function on as many networks as possible. One way to accomplish that is to design and build the product using the Texas Instruments’ Sitara processor.

Versions of this powerful processor contain the Programable Real-Time Unit and the Industrial Communication Subsystem (PRU-ICSS), a hardware block in the processor. This firmware accessory allows the host product to detect the type of Ethernet protocol to which it’s connected. It then loads the industrial application to the Sitara during run-time. Because the 1-Gb/s, 32-bit Arm processor has this capability, it can replace the ASICs or FPGAs normally used to implement the non-changeable fixed protocol.

Understanding PRU-ICSS

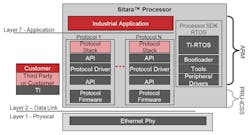

Communications with the most popular industrial protocols is facilitated via the PRU-ICSS in Sitara processors. The PRU-ICSS is a co-processor subsystem containing PRU cores and Ethernet media access controllers (EMACs) that implement the industrial Ethernet and fieldbus protocols through firmware. Therefore, using the PRU-ICSS makes the main Arm cores available for other control and data-processing functions.

Some of the Sitara processors supporting PRU-ICSS include the AM335x, AM4x, AM5x and AM6x. They’re based on the Arm Cortex-A series. The first two models provide two standard Ethernet ports, the AM5x offers four ports, and the AM6x has six ports. These processors run Linux, TI-RTOS, and Android OSs. Software development kits (SDKs) for these processors are available.

The figure explains a lot as it shows the software deployment in a Sitara processor. TI offers several evaluation products and reference designs to get you started using PRU-ICSS with the Sitara processors.

If you need training, watch the TI video where systems engineer Thomas Mauer introduces the PRU-ICSS protocols built on top of a Processor SDK to enable real-time industrial communications for TI Sitara embedded processors.

Other videos can help you learn more about the TI reference designs that feature multi-protocol industrial Ethernet detection firmware like PRU-ICSS. That firmware supports the detection of the top industrial Ethernet protocols, including EtherCAT, EtherNet/IP, PROFINET, SERCOS III, and PowerLink.

Time-Sensitive Networking (TSN)

TSN is the feature that implements deterministic capability in an industrial Ethernet network. It’s basically a set of software extensions defined by the Institute of Electrical and Electronic Engineers (IEEE). These enhancements are designated by the 802.1 prefix. The supplements are based on the IEEE’s 1588 precision timing standard, particularly the 802.1AS-Rev that provides the basic timing and synchronization for time-sensitive applications.

Sponsored Resources:

About the Author

Lou Frenzel

Technical Contributing Editor

Lou Frenzel is a Contributing Technology Editor for Electronic Design Magazine where he writes articles and the blog Communique and other online material on the wireless, networking, and communications sectors. Lou interviews executives and engineers, attends conferences, and researches multiple areas. Lou has been writing in some capacity for ED since 2000.

Lou has 25+ years experience in the electronics industry as an engineer and manager. He has held VP level positions with Heathkit, McGraw Hill, and has 9 years of college teaching experience. Lou holds a bachelor’s degree from the University of Houston and a master’s degree from the University of Maryland. He is author of 28 books on computer and electronic subjects and lives in Bulverde, TX with his wife Joan. His website is www.loufrenzel.com.