Thermal Management in Rugged Computer Systems

This article appeared in Microwaves & RF and has been published here with permission.

As rugged computer systems designed for military programs grow more powerful and more complex, keeping these systems cool under harsh conditions becomes more challenging. Customers and suppliers have a variety of cooling techniques they can and do use, including conduction, convection, air flow-through (AFT), liquid flow-through (LFT), and fluid flow-through (FFT).

For many years, conduction cooling has played a major role in the thermal management of rugged systems, but there are limits to how much heat can be dissipated by conduction cooling alone. Most traditional conduction-cooling methods are unable to disperse the heat generated by today’s hotter cards. Where once it was commonplace to have 50-W cards, 120- to 200-W cards are becoming more common.

Conduction Cooling

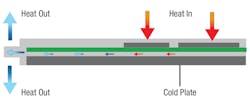

Conduction cooling is the transfer of heat through solid materials. A common example might be the conduction-cooled chassis mounted onto a cold plate (Fig. 1). Heat generated inside the chassis by the electronics flows into the chassis aluminum sidewalls and down into the cold plate.

At the board level, a similar mechanism for conduction cooling transfers heat from the components through a conduction frame to the card edge and beyond to the “cold wall” of the chassis.

Convection (Air) Cooling

Convection cooling transfers heat from a card into the ambient air using airflow. There are two basic types of convection cooling: Natural convection relies on natural airflow, while forced convection requires air flow from fans or blowers. Forced convection is much more effective at cooling than natural convection but requires the added complexity and reliability challenges of the air movers.

Air Flow-Through Cooling

AFT technology uses a heat-exchanger frame (Fig. 2), which prevents the cooling air from encountering the electronics. On both the inlet and the exhaust sides of the card, a gasket mounted inside the chassis seals the card’s internal air passage to the chassis side walls (Fig. 3). These seals prevent air from being blown into the chassis and protect the internal electronics from the harsh external environment.

By providing a thermal path of lowest possible resistance, an AFT-cooled chassis can deliver the following features:

- Cooling capacity of up to 200 W per slot

- Environmental sealing to accommodate the harshest environments

- Cooling without exotic materials or fluids associated with liquid or evaporative cooling

One of the benefits of AFT is that the cooling air is in very close proximity to the high-power components on both the base card and mezzanine cards, providing a direct path to the cooling air. Because the air doesn’t come in direct contact with the components, it needn’t be filtered.

Instead of cards having to share cooling air or share the thermal interface into which they conduct heat, each AFT card has its own inlet and exhaust (Fig. 4).

Liquid Flow-Through Cooling

Cards with power densities above 200 W call for a different cooling approach because air isn’t the most efficient medium for transferring heat. That’s where liquid flow-through (LFT) cooling comes in.

Though it’s like AFT in some respects, LFT leverages a liquid-cooled system rather than an air-cooled heat exchanger. Instead of a conduction frame, LFT uses a liquid cooling frame (Fig. 5) that employs inlet and outlet quick-disconnect (QD) liquid connectors. A liquid pump handles the chassis/system level.

The cooling capacities of LFT are quite remarkable. For example, a common fluid used in LFT systems is polyalphaolefin (PAO) oil, which conducts and removes heat much more effectively than air, theoretically enabling LFT systems to cool cards up to 1 kW. As processing devices increase in power dissipation and density, LFT may be required to maximize the utilization of these devices.

Fluid Flow-Through Cooling

Curtiss-Wright has patented a system known as fluid flow-through (FFT) cooling (Fig. 6). In this case, the fluid can be either liquid or air. The main difference is that FFT has fixed channels (air-cooled or liquid-cooled) built into the chassis.

In addition, it uses conduction-cooled modules—conduction frames attached to printed wiring boards (PWBs)—whereas AFT has the air-cooled heat-exchanger channel within a frame attached to the PWB. FFT allows for the highest net airflow rate because it requires no sealing. You can even use standard conduction cards.

The benefits of the FFT approach are:

- The air- or liquid-cooled channels are fixed (brazed or bonded) into the chassis, eliminating problems with separable interfaces.

- There are no AFT seals that might suffer pressure blowouts.

- There are no LFT connectors to leak or drip and harm the system

When designing a rugged computer system, it’s important to consider thermal management as a system-level issue. Focusing on thermal management at the card level fails to consider how all of the modules installed together in a semi-closed system might affect each other.

Learn More

- Thermal Management in Rugged Computer Systems white paper

- Understanding Intel Processor Throttling for Defense Applications

Ivan Straznicky is CTO for Curtiss-Wright Defense Solutions.

About the Author

Ivan Straznicky

CTO and a Technical Fellow, Curtiss-Wright Defense Systems

His responsibilities include leading and supporting advanced technology innovation and initiatives in a collaborative and efficient manner. Subject matter areas include thermal management, high speed signal integrity, reliability, hardware and mechanical design, and electronics manufacturing. Ivan has over 35 years experience in the defense & aerospace electronics industry in manufacturing, engineering, technology and management.