What you’ll learn:

- Difficulties of efficiently collecting, processing, and storing the masses of data generated by the modern smart factory.

- Potential solutions, including edge computing.

- How NAND flash storage can meet edge-processing computing power and storage challenges.

The modern factory no longer consists of machines operating independently. The adoption of the networking, microcontroller, and sensor technologies from the Internet of Things (IoT) has led to the industrial IoT (IIoT) or “Industry 4.0.” In these smart factories, machines are networked to enable local coordination, monitoring, and control.

IIoT can revolutionize the factory floor through the effective use of data collected from machines and sensors. This data may have been available in the past, but it wasn’t easy to collect and exploit because multiple types of data, from a variety of sensors, needed to be integrated. Embedded and networked controllers now allow information from different interfaces and in different formats to be read, processed, and shared.

Smart factories are able to make more efficient use of the resources in an organization to improve productivity and profitability. Data from all parts of a system can be used to improve efficiency by optimizing the scheduling of work and maintenance. Ultimately, a factory could generate a thousand terabits of data per month, so the challenges are how to efficiently collect, process, and store this information.

IIoT systems have made use of cloud-based computing to enable remote monitoring and management for data archiving, and to perform more complex analysis. With the rapid growth in network sizes and data volumes, the cloud-computing model is encountering some serious challenges. These include high latency and making efficient use of available bandwidth.

Moving Computing to the Edge

Edge computing is one solution. It puts computing and storage resources at the edge of the IIoT network, close to the devices and data sources, thus reducing dependency on the cloud.

Edge processors must have sufficient processing and storage capabilities to perform the complex processing that’s required. These workloads are increasingly turning to machine-learning (ML) and artificial-intelligence (AI) approaches. AI/ML enable very sophisticated decision-making to be performed autonomously, but they require rapid access to very large data sets.

The edge node also acts as a gateway to the cloud. On one side, it communicates with the network of “things” (machines, operators, transportation, warehousing, and storage), and on the other with the internet and cloud services. This means it can manage data collection, firmware updates, activity logs, and user interfaces. Therefore, the node needs to provide secure and reliable storage for large volumes of data.

The typical edge compute node in an industrial environment is a ruggedized modular computing system in the form of a programmable logic controller (PLC). These have some specific constraints that affect the selection of the best storage solution. They’re often very compact, without the expansion slots seen in enterprise servers, for example. The system needs to be robust to shock and vibration, and operate in the industrial temperature range of −40 to +85°C.

Flash: The Ideal Storage Solution for the Edge

Edge processing requires both computing power and storage. Finding the right technology for both is essential. NAND flash, as used in solid-state drives (SSDs), is ideal for use in PLCs. It has the advantages of being robust (because there are no moving parts), low power consumption, and high performance.

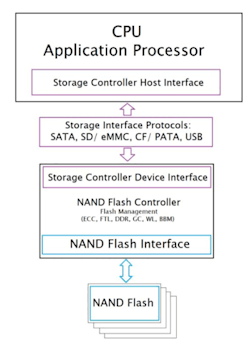

In addition to fast access and low latency, the real-time nature of edge computing also requires predictable performance. The design and firmware of Hyperstone flash controllers can be fine-tuned for specific use cases, to help ensure an optimal balance between I/O performance and background tasks (Fig. 1).

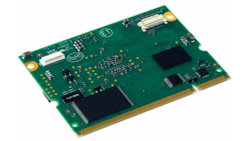

PLCs often have limited space available for extra components. This means that adding an SSD or memory module isn’t always possible. In this case, the flash memory and controller can be integrated on to the main circuit board, a solution Hyperstone calls Disk on Board (DoB). Implementing a DoB solution does mean slightly more design work, but it also provides a more robust solution. Having everything on the main board eliminates cables and connectors, which reduces the bill-of-materials (BOM) cost and eliminates failure modes caused by those connections (Fig. 2).

The usable life of flash storage depends on sophisticated algorithms for wear leveling and minimizing write amplification. The firmware in the flash controllers can be tuned for the access patterns of a specific application to maximize the lifetime of the flash memory.

The storage also must be robust to power loss so that there’s no corruption or loss of data. For example, the system needs to be able to reboot and carry on functioning as soon as power is restored. Hyperstone controllers include several functions to ensure data isn’t lost, even if there’s an unexpected power failure.

It’s also important to be able to monitor the performance of the storage system to enable timely replacement before failures cause downtime or data loss. Hyperstone controllers monitor raw error rates and other parameters to determine the health of the flash memory.

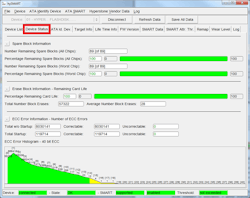

Users of a storage module with a Hyperstone controller can use the hySMART utility to monitor the system’s status. The tool uses real-time health parameters, including ATA standard and Hyperstone-specific SMART data, to calculate the lifetime status. This is then displayed through a graphical user interface (GUI). Having a clear overview of an operating storage system is key, especially in smart factories and industrial environments where an unexpected failure can have a significant impact on overarching operations (Fig. 3).

Alternatively, design engineers can also apply the Hyperstone use-case tracker to record detailed information about how an application uses the flash memory. By capturing exact data patterns, the size of data transfers, and the total amount of data written and read, the design of a storage module can be optimized for its unique use-case. Thus, the designer is able to fine-tune the optimal flash configuration for a specific application. This can be done if you’re designing a new storage system from scratch or repurposing an existing design. It improves performance and maximizes the lifetime of the flash memory.

The Future with Edge Computing and Flash Storage

Industrial edge computing combines the benefits of networked IIoT nodes and cloud computing in a local computing resource. It supports low-latency access to mass storage for resource-intensive applications. It also minimizes bandwidth use and server resources, both of which are finite and cost money.

But ultimately, all of this depends on fast, reliable storage.

NAND flash is the ideal storage medium for industrial edge computing. Many storage modules are possible. For example, implementing a DoB solution helps minimize the space requirements and eliminates connectors as potential points of failure.

The rapidly increasing capacity and falling price per bit of flash memory makes NAND flash an attractive choice for those designing storage solutions. However, it’s the capabilities of high-end flash-memory controllers that enable ever more functionality in edge devices.

The flash-memory controller is a vital component in storage solutions, and the selection of a quality controller is the key factor for reliable storage in industrial edge computing. To meet the stringent requirements of the smart factory, the controller must provide predictable performance and longevity, while operating in an industrial environment.

Axel Mehnert is the VP of Marketing at Hyperstone.