Electronic Components for Hostile Space Environments

Members can download this article in PDF format.

Designing electronic equipment for hostile environments like industry, the automobile, and the military is a major challenge. Topping the list, though, is system design for space. There’s probably no greater hostile environment than outer space. We know this from past experience in designing satellites for deep-space probes and moon shots.

Space isn’t just an open vacuum—it’s also a seriously hazardous place. The temperature extremes are well-known, but the invisible radiation is the major problem. Dealing with that involves finding the electronic parts that can survive such an environment. The solution is radiation-hardened components.

Sponsored Resources:

The Rationale

The escalating need for radiation-hardened parts is due to the ramp-up in space activities, particularly the considerable activity in low-Earth-orbit (LEO) satellite deployment. Constellations of small LEO satellites are going to be used to build new worldwide telecommunication networks.

Radar satellites are being developed for improved earth observation. Optical observation platforms are another popular application. Other satellites include those for navigation, weather, and the usual communications functions that typically involve geosynchronous satellites.

Most military aircraft are subject to radiation, too. All of these require some protection from space radiation. Additional applications include future moon projects and the ongoing Mars exploration efforts. All need radiation protection.

Radiation

Radiation is the process by which energy is transferred from source to another object. The energy is in the form of electrons, protons, neutrons, ions, photons, or other particles. There are three main sources of the damaging radiation: cosmic rays from distant galaxies, solar radiation, and radiation belts. Cosmic rays typically consist of high-energy protons as well as alpha particles (the nucleus of a helium atom with two protons and two neutrons), ions, x-rays, and gamma rays from galaxies far, far away.

Radiation from our sun is in the form of protons, ions, and x-rays as well as plasma and magnetic flux. An example of a radiation belt is the earth’s Van Allen belt. It surrounds the earth with charged particles, such as electrons and ions from the sun, that are captured by the earth’s magnetic field.

Nuclear radiation is another problem. It comes from nuclear reactors, particle accelerators, and nuclear weapons. A potential source is an electromagnetic pulse (EMP), which can be created by even a small nuclear explosion, will generate radiation harmful to most electronics.

This radiation is constantly present in space and all space equipment is subject to damage or serious malfunction. Semiconductor devices are the primary victim of this radiation and therefore must be protected.

When a radiation particle strikes an IC or transistor, it impacts the electrons, scrambling them and either stopping all operation completely or introducing errors or other faulty operation. Some radiation may destroy the device. The solution is radiation-hardening.

Radiation-Hardening

Radiation-hardening is a process used by IC manufacturers to protect the chips from the radiation sources that it may encounter. The process varies with the manufacturer and includes a variety of techniques. ICs can be hardened by making them on an insulating substrate in place of the usual semiconductor base. Silicon-on-insulator (SOI) or silicon-on-sapphire (SOS) are typical bases. Use of a wide-bandgap substrate like silicon carbide or gallium nitride is helpful in hardening some devices.

As it turns out, bipolar transistor circuits are less susceptible to some radiation than CMOS circuits. Regarding memory circuits, SRAM is better able to handle some radiation than DRAM. And magnetoresistive RAM (MRAM) is sometimes used for non-volatile memory needs.

Another technique involves physical shielding with special metals and materials. Some of the other IC hardening techniques are proprietary.

While these physical hardening methods are effective, some additional protection can be derived from logical techniques. One of these is redundancy. For example, if an MCU is utilized, back it up with two or three additional MCUs. Another technique is to use error detection and correction techniques. Extra circuits can add multiple parity bits to identify errors and correct them. This technique is effective in reading from and writing to memory.

Over the years, many techniques have been employed and multiple vendors have been approved to supply hardened products. Today, an approved vendor is identified as being on the Qualified Manufacturer List - Class V (QMLV), also known as MIL-PRF-38535. The term radiation-hardened assured (RHA) is another reference to approved products. These designations confirm the devices as having been tested with a total ionizing dose (TID), which is a measure of the total amount of radiation received, and the single event effect (SEE), which indicates what specifically occurs when a particle strikes the device.

Radiation-hardening is a complex and variable process. You can learn more about it and get expert insight into radiation effects on industrial and terrestrial applications in the Radiation Handbook for Electronics.

Radiation-Hardened Products

Almost any type of IC is available in a radiation-hardened version, although the number of options is limited. Plus, there are fewer RHA vendors. One manufacturer that’s been supplying radiation-hardened semiconductors to the space industry for over 60 years is Texas instruments. The company offers an extensive list of hardened space-grade parts.

That list includes everything from simple logic ICs like the popular 5400 series TTL gates and flip-flops to the widely used MSP430 MCUs. Multiple other products are available, such as amplifiers, memory, power management, data converters, interface, clocks, sensors and even motor control. A complete summary can be found in the TI Space Products guide.

One good example of a space-hardened IC is a current-sense amplifier (CSA). This IC provides a superior way to monitor the main power source and other critical circuits in a satellite.

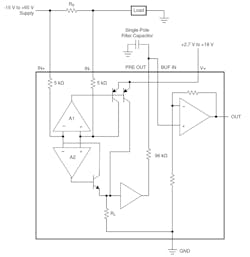

Take, for example, the INA901-SP, one of TI’s QML Class V CSAs (see figure). It can be used to detect overcurrent events at various point-of-load connections to help ensure a long life for a satellite.

The INA901-SP can handle either high- or low-side current-sensing designs. Such flexibility makes it useful in many parts of a satellite’s power system. A key feature of this −15- to +65-V device is its ability to endure voltages like transients greater than the supply voltage on its inputs.

Sponsored Resources:

About the Author

Lou Frenzel

Technical Contributing Editor

Lou Frenzel is a Contributing Technology Editor for Electronic Design Magazine where he writes articles and the blog Communique and other online material on the wireless, networking, and communications sectors. Lou interviews executives and engineers, attends conferences, and researches multiple areas. Lou has been writing in some capacity for ED since 2000.

Lou has 25+ years experience in the electronics industry as an engineer and manager. He has held VP level positions with Heathkit, McGraw Hill, and has 9 years of college teaching experience. Lou holds a bachelor’s degree from the University of Houston and a master’s degree from the University of Maryland. He is author of 28 books on computer and electronic subjects and lives in Bulverde, TX with his wife Joan. His website is www.loufrenzel.com.