Revolutionize Remote Wireless Monitoring with AI and High-Energy Lithium Batteries

What you’ll learn:

- Our nation’s aging infrastructure requires the implementation of Infrastructure 4.0 to better manage and maintain these valuable assets.

- Remote wireless devices are being used to improve management and maintenance of hard infrastructure to provide greater insight enhanced by AI.

- Ideally, low-power wireless devices deployed throughout hard infrastructure need highly energetic batteries capable of supporting bidirectional communications necessary to provide actionable real-time data to better manage and maintain these assets.

- Bobbin-type LiSOCl2 batteries deliver high capacity, high energy density, an extended temperature range, and very low annual self-discharge rate, suiting them for long-term deployments in harsh environments.

Hard infrastructure is essential to our society, encompassing everything from energy exploration and distribution to solid-waste management, wastewater treatment, water, gas and electric utilities, environmental monitoring, transportation infrastructure, smart cities, and much more.

Unfortunately, America’s hard infrastructure is rapidly aging, causing a growing crisis involving public safety, deferred maintenance, operational stress, labor shortages, cybersecurity, and regulatory compliance, to name a few. These difficult challenges demand the implementation of Infrastructure 4.0 to provide forward-looking information and actionable data enhanced by artificial intelligence (AI).

The long-term benefits of Infrastructure 4.0 will be significant, including more proactive maintenance; preemptive warnings; improved connectivity; greater management control (i.e., SCADA); improved environmental quality; greater cost efficiencies; and making data more visual and intuitive.

Going Remote

At the heart of Infrastructure 4.0 will be remote wireless devices powered by ultra-long-life industrial-grade lithium batteries. These robust energy sources must be capable of powering bidirectional, two-way wireless communications using IoT/edge or fixed-base communications technology.

Another important factor is the operating environment, especially for devices deployed in hard-to-access locations and harsh environments. Remote locations demand a robust, long-life power source since the cost of labor to replace a battery far exceeds the initial cost of the device itself. In addition, extreme temperatures can drain cell capacity and accelerate battery self-discharge to greatly reduce operating life.

These factors are all highly interrelated, demanding highly comprehensive end-to-end solutions that can answer these five key questions:

- Is the solution smart and intuitive?

- Is it a comprehensive end-to-end solution?

- Is the solution simple, scalable, and flexible?

- Is the data cybersecure?

- Is the right battery being specified?

What follows is a brief examination of various technical issues surrounding these questions, utilizing actual case studies to demonstrate their practical application.

Making Data Smarter and More Intuitive

Enhanced data intelligence occurs at multiple levels: first by improving data creation (the quality and quantity of the information); second, by permitting more robust data management and reporting; and third, by enhancing data utilization versus legacy platforms such as PLC and TRU.

The proper upgrade enables data to become more visual, integrated, and scalable, using AI and machine learning to autonomously enable greater data intelligence. Optimized solutions also need to adapt to cloud-based and hard-wired technology platforms without intensive coding or remote management.

Comprehensive End-to-End Solutions from Software to Power Supply

Partial solutions are inherently inefficient. Intelligent edge-to-edge solutions enhance performance and reduce the cost of ownership through a holistic hardware/software solution manageable from a single source.

Triggers from field sensors generally benefit from remote cameras that provide visual verification. In addition, all data interfaces should be sensor agnostic, fast and secure, rugged and waterproof, flexible to accommodate multiple configurations (analog, serial, and discrete input), and seamlessly integrate with existing third-party software.

Often overlooked is the critical need for an energetic and robust power-management solution using ultra-long-life lithium batteries. Such a power source should be capable of delivering high pulses to power bidirectional wireless communications.

Keep It Simple, Flexible, and Scalable

In a world of constant change, wireless solutions need to be modular and flexible, evolving to address dynamic market conditions, future growth opportunities, and increasingly stringent regulatory reporting.

In a tightening labor market, you can no longer assume that devices will be installed by seasoned and experienced personnel. Therefore, “smart” solutions need to be easily installed, plug-and-play, and fully autonomous without requiring specialized coding skills.

Comprehensive Cybersecurity is Imperative

The highly disruptive Colonial Pipeline hacking incident underscores the need for military-grade cybersecurity from the bottom up to protect various access points.

For example, communications between the platform and the wireless device can be intercepted to corrupt the device configuration or modify the data. Bluetooth communications channels can become compromised to gain unauthorized configuration access. API sessions also could be hacked to gain programmatic access to specific user accounts.

Any best practices model must combine secured hardware and software along with fully encrypted communications. The gold standard for reducing vulnerability to cyberattacks when transmitting sensitive data is TLS v1.3, which applies the strongest encryption libraries to all data transmitted to and from IIoT devices. In addition, all firmware must meet TLS v1.3 standards.

Adopting the most stringent TLS v1.3 protocols will increase communication efficiency, which extends battery life. Combining lean technology with higher-capacity/higher-energy-density batteries serves to further extend product longevity.

Specifying the Right Battery Is Critical

A remote wireless device is only as reliable as its power supply, since battery failure causes system failure. While the choice of battery is a critical consideration, common misperceptions abound that all batteries are created equal—a mistake that can lead to compromised solutions.

There are two types of low-power devices:

- Those that draw average energy (background current and pulses) measurable in microamps, typically requiring an industrial-grade primary (non-rechargeable) lithium battery.

- Those that draw average energy (background current and pulses) measurable in milliamps, typically requiring an energy-harvesting device combined with a lithium-ion (Li-ion) rechargeable battery.

Every low-power application has specific technical requirements, such as sampling frequency; the amount of energy consumed while in “active” mode; cell capacity and energy density, minimizing losses caused by long-term exposure to extreme temperatures; and other factors that affect a battery’s self-discharge rate.

Identifying ways to minimize energy consumption is especially critical for devices using bidirectional wireless communications, as this requirement draws additional energy. Ideal solutions typically combine a low-power communications protocol, low-power chipsets, and proprietary techniques designed to limit power consumption while in "active" mode.

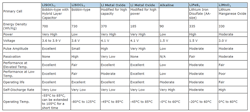

Commercially available primary battery chemistries include alkaline, iron disulfate (LiFeS2), lithium manganese dioxide (LiMnO2), lithium thionyl chloride (LiSOCl2), and lithium metal-oxide (see table). Among these choices, bobbin-type LiSOCl2 chemistry stands apart for its higher capacity and energy density, resulting in extended battery life. Bobbin-type LiCOCl2 chemistry also features the widest temperature range and the lowest rate of annual self-discharge, making it the preferred choice for long-term deployments in remote locations and harsh environments.

How the Passivation Effect Reduces Battery Self-Discharge

All batteries experience some amount of annual self-discharge, as chemical reactions exhaust available capacity even when a cell is disconnected or in storage. The rate of annual self-discharge is impacted the cell’s current discharge potential, the quality of the raw materials, and, most importantly, by the passivation effect.

Passivation occurs when a thin film of lithium chloride (LiCl) forms on the surface of the lithium anode, which limits reactivity. Whenever a load is placed on the cell, the passivation layer initially causes high resistance and a temporary dip in voltage until the discharge reaction begins to dissipate the LiCl layer—a process that repeats each time the load is removed.

The passivation effect can vary based on how a cell is manufactured and the quality of the raw materials. Other factors affecting passivation include current capacity; length of storage; storage temperature; discharge temperature; and prior discharge conditions, as removing the load from a partially discharged cell increases the level of passivation relative to when it was new. Passivation increases longevity, but too much of it can overly restrict energy flow.

Standard bobbin-type LiSOCl2 cells are unmatched for their ability to harness the passivation effect. However, they're unable to generate high pulses due to their low-rate design. This challenge can be easily overcome by adding a patented hybrid layer capacitor (HLC).

In essence, the bobbin-type LiSOCl2 cell delivers low levels of background current while the HLC delivers high pulses to power two-way wireless communications. The patented HLC features a unique end-of-life voltage plateau that can be interpreted to deliver "low battery" status notification for routine battery replacements.

Additional factors also must be considered when specifying batteries:

- Current consumption in "active" mode (the size, duration, and frequency of pulses), and how much energy is being consumed in "stand-by" mode (the base current).

- Storage time (as normal self-discharge diminishes capacity).

- Prolonged exposure to extreme temperatures during storage and in-field operation.

- Equipment cutoff voltage (exhausting cell capacity and/or extreme temperatures can cause voltage to drop too low to allow the device to operate.

Two Real-Life Examples

With fresh water being a precious commodity, the municipal water system of Orange County, Fla., relies on reclaimed wastewater to irrigate golf courses, resorts, and residential gardens. Dependent on the same reclaimed water storage tanks, residential customers didn’t have sufficient water for their gardens when golf resorts were watering the greens.

Ayyeka Wavelet devices track water usage at golf courses and resorts to coordinate water supplies for residential customers (Fig. 1). Furthermore, detailed tracking of reclaimed water usage enables Orange County’s Public Works Department to proactively plan for the placement of additional reclaimed storage tanks to meet gradually increasing demand. Highly energetic bobbin-type LiSOCl2 batteries support bidirectional wireless communications while ensuring maximum uptime with less-frequent battery change-outs.

With over 600 miles of water mains, Erie County’s pressure reducing valves (PRVs) serve to prevent stress on water mains that can lead to pipe leaks and bursts, which is especially critical to a 100-year-old system that serves over one million people.

Previously, service crews lacked data intelligence to anticipate potential ruptures to the main water line. Ayyeka delivered a comprehensive end-to-end solution using Wavelet devices to continuously monitor pressure levels in PRVs, making sure they function optimally and providing automatic text message, email, or automated phone call alerts if pressure levels begin to drop.

Field asset intelligence (FAI) software is used to detect small leaks before they lead to costly and disruptive water main ruptures. This is a nationwide problem, as the American Society of Civil Engineers concluded that leaking pipes are responsible for the loss of 6 billion gallons of treated drinking water each day (Fig. 2).

LiSOCl2 Batteries Aren't Created Equal

Comparing batteries with identical chemistries can be difficult, as the effects of a higher self-discharge rate may not become apparent for years, and predictive models often underestimate the passivation effect as well as prolonged exposure to extreme temperatures.

In reality, major significant differences exist between the highest-quality bobbin-type LiSOCl2 cells that feature a self-discharge rate as low as 0.7% per year and lower-quality cells with a self-discharge rate as high as 3% per year. While seemingly small, these differences can really add up over time, as an inferior quality cell may lose 30% of its capacity every 10 years solely because of self-discharge.

Those differences aren't always readily distinguishable, though. Therefore, you need to perform thorough due diligence by obtaining fully documented long-term test results as well as in-field test data using comparable devices under similar loads and environmental conditions.

Implementing a robust and secure Infrastructure 4.0 solution can be highly beneficial, resulting in greater data intelligence, extended battery life, and a lower cost of ownership.