Making the Case for Conductive Elastomer and Form-in-Place EMI Gasket Materials

What you'll learn:

- What are electrically conductive elastomer gaskets and what materials are used to build them?

- EMI shielding material options.

- Results of galvanic corrosion tests on aluminum alloys of electrically conductive elastomer or FIP gasket.

Use of electrically conductive gaskets with ENIG (electroless nickel immersion gold) plated circuit boards has prompted questions from design and application engineers about corrosion that may occur when these gaskets come into contact with ENIG boards. Specifically, what are the corrosion effects of nickel-graphite, silver-aluminum and nickel-aluminum filled EMI shielding materials on ENIG circuit boards?

To answer these questions, Parker Chomerics engineers conducted a number of standardized tests and report their results and analysis.

Quick Review: ENIG, Corrosion, and New-and-Improved Filler Materials

ENIG is a popular plating technique for printed circuit boards (PCBs). ENIG is one of the surface finishes used as an interface between electromagnetic-interference (EMI) shielding gasket systems and the PCB. The immersion gold layer protects the underlying nickel from oxidation/passivation over its intended life. It’s a multifunctional PCB surface finish used for soldering, wire bonding, and general electrical conductivity.

IPC International, the global association that helps OEMs, EMS, PCB manufacturers, and suppliers build electronics better, details the industry ENIG performance specification in the IPC-4552A international standard.

Electrically conductive elastomeric gaskets are specifically designed to address progressive requirements within the EMI and electromagnetic-compatibility (EMC) marketplace. These revolutionary materials, consisting of electrically conductive particles dispersed within a silicone, fluorosilicone, or EPDM (ethylene propylene diene monomer) resin system, provide an EMI shielding gasket capable of offering both electromagnetic shielding and a degree of environmental protection. Filler particle material technologies are often nickel-graphite, silver-aluminum, and nickel-aluminum.

Silver-plated aluminum-filled silicone and fluorosilicone electrically conductive elastomer gasket materials have been used for decades for both EMI shielding and environmental protection. To further improve environmental protection and increase corrosion resistance, however, nickel-aluminum particle-filled conductive elastomers present an ideal solution due to their corrosion resistance against aluminum. The nickel-aluminum filler technology was then expanded on by adding the fillers into EPDM resin systems for chemical and fuel resistance, as well as in form-in-place (FIP) gasket materials.

Exploring Gasket Material Options

Electrically conductive elastomer gaskets consist of a homogeneous dispersion of electrically conductive particles, process modifiers, and additives within an elastomer binder system. Traditional electrically conductive fillers include pure silver, silver-plated copper, silver-plated aluminum, silver-plated glass, and nickel-plated graphite.

Silicone- and fluorosilicone-based resin systems are typically the material of choice primarily due to processability, excellent compression set performance across a wide temperature range, and the ability to compress at low closure forces. EPDM-based resin systems are generally used in applications exposed to harsh chemicals.

Here, the following analysis focuses on electrically conductive elastomer and FIP gasket materials that have been proven to simultaneously provide the best corrosion resistance (per Parker Chomerics test method CHO-TM100) and the highest degree of shielding effectiveness after long-term aging tests of any EMI shielding elastomer gasket material.

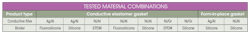

Gaskets included in this evaluation were as follows:

A Primer on EMI Shielding Material Options

EMI-shielding-grade elastomers offer a wide range of design flexibility and can be manufactured into almost any shape using molding, extrusion, form-in-place, or die-cutting processes. Thought should also be given to the manufacturability and ease of assembly of a particular EMI shielding solution—this is especially true for electronic devices produced in high volume.

Extruded Elastomer Gaskets

Extruded electrically conductive elastomer gaskets can be supplied in a wide range of solid and hollow cross-sectional geometries. Compared to solid configurations, hollow profiles require less closure force and reduce design complexity by allowing for thinner covers, fewer fasteners, and greater deflection ranges.

Thus, hollow extruded profiles are ideal for use in applications such as appliance door sealing, where it’s often difficult or inconvenient to generate high closure forces, and where there may be significant tolerance buildup over long lengths. Extrusion-grade conductive elastomers can be supplied in forms that include standard or custom lengths for high-volume applications, spliced O-rings, and four-corner spliced gaskets.

Molded Elastomer Gaskets

Molding-grade electrically conductive elastomer gaskets are typically manufactured by traditional compression or injection-molding techniques. The molding process can produce conventional sheet stock in a variety of thicknesses ranging from 0.020 in. (0.508 mm) to 0.125 in. (3.175 mm) as well as various standard and custom-molded geometric profiles.

Specialized molding techniques can also “vulcanize” a gasket directly onto an enclosure housing, simplifying both the design and assembly of an enclosure. In addition, elastomers can be molded with fabric reinforcement, providing world-class mechanical tear resistance.

Form-In-Place Gaskets

Electrically conductive FIP gaskets can be precisely dispensed onto the narrowest possible flange, allowing for smaller package sizes and increased space for PCBs and other system components.

Not only do these materials provide excellent adhesion to various surfaces, including chromate treated aluminum, they also offer low compression set for long-term sealing, low Shore A hardness for reduced closure force, and high tensile strength and elongation for gasket damage resistance in handling.

Additional benefits offered by FIP gasket systems include either fast moisture or thermal cure systems, and lower overall costs of ownership through decreased assembly labor and supply logistics in high-production environments.

Galvanic Corrosion Testing and Findings

Galvanic corrosion tests were performed (in accordance with Parker Chomerics Test Method CHO-TM100) to determine, in a quantitative manner, the corrosivity toward aluminum alloys of the electrically conductive elastomer or FIP gasket after exposure to a salt-fog environment.

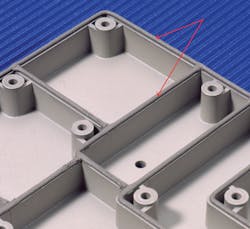

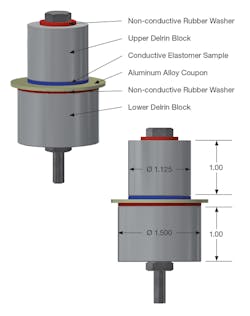

The test fixture shown below illustrates how the electrically conductive elastomer and FIP gasket and aluminum coupon (simulating an aluminum mating flange) are held in contact by compression between two cylindrical Delrin blocks. Compressive force is supplied by a central stainless-steel bolt that’s environmentally sealed on each end using a non-conducive gasket to prevent fluid from penetrating into the middle of the fixture.

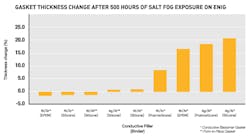

The neutral salt-fog exposure for this evaluation was in accordance with ASTM B117 for a duration of 500 hours. After the test, samples were disassembled, cleaned, and dried according to the test method and subsequently evaluated in a controlled lab.

The corrosivity of the conductive elastomer material is proportional to the weight loss of the aluminum alloy coupon. Weight loss of the coupon is calculated as follows:

Weight Loss (mg) = [Initial Weight (g) – Final Weight (g)] × 1000

Three fixtures were tested for electrically elastomers and two for form-in-place materials given the number of ENIG coupons available (test results were averaged):

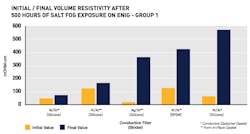

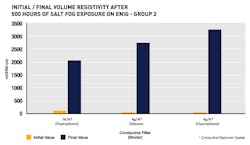

Volume-Resistivity Calculations

A four-point pressure probe digital ohmmeter with a measuring range of 10-4 to 104 Ω was used to measure volume resistivity.

The volume resistivity was calculated from the following formula:

ρ = RA / L

where ρ = volume resistivity (Ω-cm); R = measured resistance (Ω); A = area of conductive elastomer (cm2); and L = measure thickness (cm).

The gasket volume resistivity test data was listed in two groups due to the range of the test results:

Interpreting the Test Results

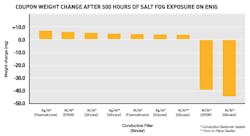

- Overall comparison: FIP gaskets outperformed even the electrically conductive elastomers after salt fog exposure.

- Within the FIP gaskets tested, a nickel-aluminum filled silicone material outperformed a silver-plated aluminum silicone material in volume resistivity and gasket dimensional change.

- Silver-plated aluminum and nickel-aluminum filled, electrically conductive elastomer gaskets outperformed the nickel-graphite-filled electrically conductive elastomers in aluminum coupon weight loss, but exhibited more gasket swelling, resulting in greater dimensional and volume resistivity changes.

- Nickel-graphite filled elastomers were highest in average coupon weight loss but showed the least change in volume resistivity and thickness.

- No significant differences determined in nickel-aluminum vs silver-aluminum filled materials, regardless of silicone or fluorosilicone resin system.

Gasket Material Choices are Application-Dependent

Choosing the right gasket requires an understanding of both electrical and mechanical requirements of the application. Shear forces, environmental effects, compression set, method of application and pricing are just some of the factors influencing the decision. Ultimately, the material spec’d also must be cost-effective, equipment- and system-compliant with military and commercial EMI/EMC and environmental test requirements.

For more information, visit www.parker.com/chomerics.