Personal Solar-Powered Desalination Unit Forgoes Filters

What you’ll learn:

- The shortcomings of conventional desalination units.

- How a new approach was developed and tested, using advanced electronics and chemistry.

- The performance achieved by this unit in field tests.

There’s clearly no need to “make the case” for the benefits of portable, on-the-spot water desalination and purification. While many portable desalination systems based on reverse osmosis are already commercially available, they’re not a good fit for remote locations due to their need for power-hungry, high-pressure pumping and continual user maintenance. If only there was a portable, maintenance-free system that could operate from solar power, right?

It looks like we’re getting very close, as a team based at MIT in conjunction with participants from Northeastern University and the U.S. Army Combat Capabilities Development Command (DEVCOM), has devised, built, and field-tested a 10-kg (22 lb.), portable (42 × 33.5 × 19 cm3) desalination unit. It removes particles and salts to generate drinking water. The system uses a multistage electromembrane processes rather than conventional reverse osmosis (Fig. 1).

The user-friendly design is self-managed—it requires no ongoing user attention since all measurement and control algorithms are embedded in its firmware, and it’s externally controlled by a smartphone. It operates at the push of a single button and automatically generates drinking water that exceeds World Health Organization (WHO) quality standards.

In addition to desalination, the system reduces suspended solids by at least a factor of 10 from the source water, resulting in crystal clear water (<1 NTU) even from the source water with turbidity higher than 30 NTU (i.e., cloudy seawater by the tide). Note: The Nephelometric Turbidity Unit (NTU) is a standard parameter used to measure the turbidity of a fluid or the presence of suspended particles in water.No Filters Needed

Key to the unit’s simplicity in field use is that unlike other portable desalination units that require water to pass through filters, this device uses electrical power to remove particles from drinking water. Eliminating the need for replacement filters greatly reduces the long-term maintenance requirements.

Instead, their unit relies on a technique called ion concentration polarization (ICP), which was pioneered by the MIT group more than 10 years ago (Fig. 2). Rather than using that well-known filtering technique, the ICP process applies an electrical field to membranes placed above and below a channel of water. The membranes repel positively or negatively charged particles—including salt molecules, bacteria, and viruses—as they flow past. The charged particles are funneled into a second stream of water that’s eventually discharged.

ICP + Electrodialysis

The process removes both dissolved and suspended solids, allowing clean water to pass through the channel. Since it only requires a low-pressure pump, ICP uses less energy than other techniques. However, ICP doesn’t always remove all of the salts floating in the middle of the channel. To compensate for this shortcoming, the researchers added a second process known as electrodialysis (ED) to remove remaining salt ions (Fig. 3).

The team used machine learning to find the optimal combination of ICP and electrodialysis modules. The optimal setup includes a two-stage ICP process, with water flowing through six modules in the first stage, then through three in the second stage, followed by a single electrodialysis process.

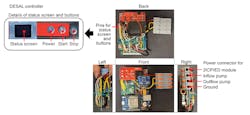

The electronics of the system provide process measurement and management with many closed-loop sensors to monitor key flow rates, concentrations, and other critical factors (Fig. 4).

Due to the nature of the application, the subassemblies as well as the final product had to be compact and rugged, given the nature of the application. It also needed to accommodate the “mixed-signal” design involving electronics as well as pumps, tubing, and fluidic controls (Fig. 5).

Test Results

After running experiments in the lab using water with different salinity and turbidity levels, they field-tested the device at Boston’s Carson Beach. In about half an hour, the device had filled a plastic drinking cup with clear, drinkable water.

The resulting water exceeded WHO quality guidelines, and the unit reduced the amount of suspended solids by at least a factor of 10. Their prototype generated drinking water at a rate of 0.3 liters per hour. It requires only 20 watt-hours per liter—an important performance metric.

“This is really the culmination of a 10-year journey that I and my group have been on. We worked for years on the physics behind individual desalination processes, but pushing all those advances into a box, building a system, and demonstrating it in the ocean, that was a really meaningful and rewarding experience for me,” said senior author Jongyoon Han, a professor of electrical engineering and computer science and of biological engineering, and a member of the Research Laboratory of Electronics (RLE).

He added, “It was successful even in its first run, which was quite exciting and surprising. But I think the main reason we were successful is the accumulation of all these little advances that we made along the way.”

Their work, including an explanation and detailed analysis of the underlying chemistry, is presented in their paper “Portable Seawater Desalination System for Generating Drinkable Water in Remote Locations” published in Environmental Science & Technology (a journal of the American Chemical Society) supported by a comprehensive Supporting Information file. Also check out this two-minute video that provides a hands-on overview:

About the Author

Bill Schweber

Contributing Editor

Bill Schweber is an electronics engineer who has written three textbooks on electronic communications systems, as well as hundreds of technical articles, opinion columns, and product features. In past roles, he worked as a technical website manager for multiple topic-specific sites for EE Times, as well as both the Executive Editor and Analog Editor at EDN.

At Analog Devices Inc., Bill was in marketing communications (public relations). As a result, he has been on both sides of the technical PR function, presenting company products, stories, and messages to the media and also as the recipient of these.

Prior to the MarCom role at Analog, Bill was associate editor of their respected technical journal and worked in their product marketing and applications engineering groups. Before those roles, he was at Instron Corp., doing hands-on analog- and power-circuit design and systems integration for materials-testing machine controls.

Bill has an MSEE (Univ. of Mass) and BSEE (Columbia Univ.), is a Registered Professional Engineer, and holds an Advanced Class amateur radio license. He has also planned, written, and presented online courses on a variety of engineering topics, including MOSFET basics, ADC selection, and driving LEDs.