Download this article in PDF format.

They may be small, sometimes almost invisible, but sensors are essential ingredients in almost every industrial system, whether powered by electricity, water, steam, wind, or waves. They’re going to be even more important in the future as the Internet of Things transforms standalone systems into a network of connected devices, almost all of them having integrated sensors. In fact, they will key players in helping commercial, industrial, government, and other large buildings reap significant energy savings, especially in heating, ventilation, and air-conditioning (HVAC) systems.

Only recently has there been an emphasis on connecting the many sensors within HVAC and other systems together to produce an “intelligent” building. The reasons for that have as much to do with recognition of the need for achieving energy efficiency as they do with the technology required to deliver it.

It’s safe to say that until the 1970s, few people paid much attention to “energy efficiency” at all—and why would they as gasoline and oil prices had remained low for decades? The wakeup call came in 1973’s oil crisis (Fig. 1), followed by another in 2000 that together increased the price of both by an order of magnitude. Energy efficiency could no longer be ignored. So today, achieving the highest possible energy efficiency is a key goal in every industry in which power conservation is essential.

Sponsored Resources:

1. It’s not hard to find the point of the “wakeup call,” when oil prices surged around 1973, sagged, and then rose again in the early 2000s. Even though have since dropped (but are still around $73 a barrel), the need for energy efficiency is now well established. (Source: U.S. Energy Information Administration)

Technology, the other primary factor, has advanced dramatically over the years. Smaller digital components have replaced larger analog versions, and wireless-communications components and systems have made huge leaps in performance, miniaturization, and in the sheer number of choices. Together, technology and the awareness of, and need for, greater energy efficiency collectively make possible the creation of more efficient buildings.

Predictive Maintenance

To be truly intelligent, all systems in the building must be able to communicate with each other in near real time, and collectively transmit data from their sensors and other components to a central point where the information can be analyzed and acted upon. In addition to reducing energy consumption, the overall goal is to enable predictive maintenance and make the environment more comfortable for its occupants.

For example, temperature sensors monitor the entire structure and sections within it; pressure and airflow sensors detect flow rates, filter performance, and other conditions; and humidity sensors complement temperature sensors to determine the comfort level in the building more precisely. The energy consumption and operational conditions in a building with hundreds of zones can be assessed and performance augmented through automated adjustments to these sensors and other equipment to optimize efficiency and comfort.

System managers, whether locally or almost anywhere via the internet, already rely to some degree on these capabilities. However, in the future, they will become far more proficient in handling building management and require far less manual operation.

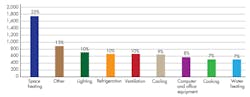

The benefits are potentially enormous. Commercial buildings consume huge amounts of energy in the U.S. (Fig. 2), resulting in annual energy costs of more than $200 billion. Even incremental increases in the efficiency of a building can reap financial benefits for the owner or operator, with the added benefit of allowing predictive maintenance to be performed based on trends in sensor operational data. Although the drive toward higher efficiency has been driven in part by the U.S. Department of Energy (DOE) and state and local governments, building owners and their tenants are also spearheading these efforts.

2. Commercial buildings consume huge amounts of energy, and space heating is the primary contributor. (Source: U.S. Energy Information Administration, 2012 data, in trillions of BTUs)

Generally speaking, the more granular the approach, the better the results. That is, buildings are increasingly being separated into zones, each having its own sensors, rather than a single floor as before. Therefore, it becomes possible to “tune” conditions very precisely. When combined with occupancy sensors that detect the presence of human activity, HVAC and lighting in a zone can be modified accordingly.

The Digital Takeover

It should come as no surprise that digital sensors are replacing their analog predecessors in HVAC systems, because they can dramatically reduce wiring costs by communicating data wirelessly via one of the many available protocols. Even if they continue to use wired connectivity, they benefit from the advantages digital technology provides in so many other scenarios, such as plug-and-play installation, hot-swap capability, and automatic reconfiguration.

Digital sensors also eliminate the need for recalibration, because the required information is stored in the sensor itself. And whether wired or wireless, one can troubleshoot these sensor networks almost effortlessly from a remote location. The sensors in the networks increasingly have self-diagnostics as well.

These sensors have also become far more accurate in recent years, and now many types have performance equal to, and sometimes better than, their analog counterparts. On top of that, they provide the benefit of continuously monitoring their own performance and reporting any anomalies through the network.

For example, TE Connectivity’s M5600 wireless pressure transducer (Fig. 3) is designed for measuring liquid or gas pressure in environments ranging from water to steam and corrosive fluids. Its integrated Bluetooth Low Energy (4.0) transceiver eliminates the need for a wired connection to provide connectivity and has a maximum range of 65 ft. The transducer is powered by a lithium coin-cell battery, with an operating life of up to two years before battery replacement. It incorporates a 24-bit ADC for analog-to-digital conversion and has accuracy of ± 0.25%. Measurement range is up to 15 klb/in.2

3. TE Connectivity’s M5600 wireless pressure transducer, which uses Bluetooth to communicate with the network, operates from a coin-cell battery.

A major change is also taking place in building-management systems that have traditionally been proprietary but are increasingly using open solutions. In addition to allowing for greater interoperability between hardware from different manufacturers, this approach dramatically simplifies the overall implementation of intelligent buildings. When HVAC controls, power management, and central plant equipment and lighting are all managed by a single solution based on an open architecture, far greater performance can be achieved at less cost and in a shorter timeframe.

Although the vast installed base of proprietary systems will take many years to transition to open solutions, it’s clear that this is the trend. Of course, there are also a variety of available open solutions, each one with its own advantages and disadvantages. So, it remains to be seen which one will ultimately become the most widely deployed. As has been the case in many other applications, it’s likely that several solutions will be used in a given building based on its advantages in a specific scenario.

Sponsored Resources:

- Brochure, Sensor Solutions for HVACR

- Trend Paper, Sensing Change: Six HVACR Trends moving the industry forward

- Now you see them, Now you don't

Related References: