How to Implement Gas Sensors for Indoor Air-Quality Applications

Metal-oxide (MOx) gas sensors, sometimes known as chemiresistors, have been used for more than 30 years in a wide range of products, most notably industrial and safety products. The largest market for these sensors has been in highly specialized, regulation-based applications where requirements are defined by independent governing agencies, and equipment is relatively expensive and intended for use by trained operators.

However, a new range of MEMs-based sensors have hit the market in the past few years, promising smaller sizes, lower prices, and embedded signal conditioners for ease of use and integration. This new class of sensors enables the electronic sense of “smell” to be added to a wide range of consumer-oriented products (including handheld and portable devices such as smartphones), with no special experience or knowledge needed by the end user.

With the growing trend for smart objects and the Internet of Things (IoT), the availability of these new sensors is creating a completely new class of applications and customers looking into MOx sensors and applications. One of the most exciting applications is in the area of indoor air quality. This article will describe the application and integration of a gas sensor into consumer products for air-quality detection.

Air Quality: Why Should We Care?

Worldwide, people spend 90% of their lives indoors, which includes our homes, offices, schools, and cars.1 Modern building methods focus on energy efficiency, which is great for our environment overall. Unfortunately, though, it also results in air quality inside buildings that’s less comfortable and occasionally unhealthy because there’s an insufficient exchange between indoor and outdoor air. The impact on indoor air quality is compounded by the many different sources of indoor air contaminants that can degrade the quality of indoor air. This includes daily activities (cooking, cleaning), materials off-gassing (furniture, paint), and even our lifestyle choices (scented candles, perfumes, etc.).

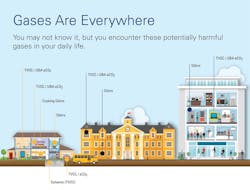

Figure 1 summarizes the different sources of poor indoor air quality. Components of air quality include particulates (e.g. PM2.5) and gases, such as carbon dioxide (CO2) and carbon monoxide (CO), and a wide range of other volatile compounds that are present at trace levels (ppm or ppb).

1. Sources of poor indoor air quality in various locations.

CO is a highly regulated safety gas, which is colorless, odorless, and tasteless. This article focuses on the CO2 and those other volatile components of air quality that prevail in our living spaces. These common sources of poor indoor air quality fall into the category of volatile organic compounds (VOCs), while certain activities and locations can have other indoor contaminants like volatile sulfur compounds (VSCs), also known as “bad” smells.

Though information about regional levels of outdoor air pollution can be relatively easy to find (e.g., the site managed by the Environmental Protection Agency), regrettably, it’s much more difficult to find information on what’s in the air in places where we spend most of our time. With knowledge comes power, and in this case, power includes the ability to change our indoor environments to increase the health, comfort and productivity of our families and ourselves.

Ways to improve indoor air quality can be as simple as turning on a fan or opening a window, especially in a bathroom or kitchen, or could include controlling HVAC systems or air purifiers. Or people could simply make conscious decisions about lifestyle activities and the types of products they use in their personal environments.

What Are MOx Gas Sensors and How Do They Work?

MOx gas sensors, used to detect various gases, are comprised of a heating element, which was traditionally a small ceramic chip. Modern sensors feature a micro hot plate produced in silicon and designed to reach accurate temperatures in the range of 100 to 400°C, while minimizing power use (reducing heat transfer). The sensors also feature a sensing material based on a metal oxide—tin oxide is the traditional choice. A number of other base materials are used, too, and a wide range of additives are available to control the material properties.

Some examples of the design and construction of the sensor element are shown in Figure 2. Sensor manufacturers might spend months or even years perfecting a specific MOx recipe and method of manufacturing to achieve detection of the targeted gases and concentrations.

2. The basic structure of a MOx sensor (left) and examples of an analog and digital device (right).

The sensor signal (resistance) is based on (1) the design of the MOx materials, (2) the operating temperature, and (3) the concentration of gases present in the air. The MOx material is heated to the target temperature (or multiple temperatures, in sequence) and the resulting resistance is measured. Resistances can range from a few hundred ohms up to gigohms, depending on the sensing materials selected, electrode design, and the operating environment.

Sensor manufacturers will typically recommend a temperature of operation (or heater control, e.g. voltage input) to achieve a specific result or set of specifications. Some modern sensor manufacturers will go further in creating an easy-to-use sensor by developing operating methods that can be dynamically controlled with software. Therefore, the user doesn’t have to consider operating temperature or how to control it and correct it for environmental variation.

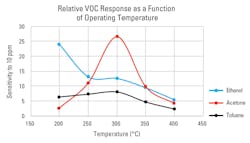

Figure 3 shows a simple example of the sensitivity of a sensor to three different VOCs, which can vary depending on the operating temperature of the sensor. In the real world, air quality is much more complex, and sensor testing includes evaluation of the effect of a wide range of VOCs on the gas-sensor response.

3. The effect of temperature on sensitivity to a target gas. By changing the operating temperature, or method of heater control, the sensor can be tuned to detect different gases.

The resistance of the MOx gas material is a function of the gas concentration of the sensor. The mathematical description for the relationship between gas concentration and conductivity follows a power law behavior as shown in the equation:2

RMOx = A·c−α (1)

RMOx = MOx resistance

A = constant, based on the MOx material used

c = gas concentration

α = exponent, based on the MOx material used

The change in resistance with changing gas concentrations could range from a few percent to several orders of magnitude, depending on the amount of gas present, the design of the MOx material, and the operating temperature selected. Larger changes in resistance are typically preferred. This is a twist on the classic signal-to-noise ratio consideration: larger response to the gas of interest (signal) compared to sensor drift and response to changing environmental conditions (humidity, barometric pressure, environmental temperature). Together, these comprise the noise. As with other measurement systems, the better the signal-to-noise, the better the result.

While traditional analog gas sensors require user calibration, some manufacturers provide calibrated output and libraries of pre-compiled code with their sensors to make integration easier.

Measuring Air Quality with Sensors

Users can integrate sensors in a wide variety of locations. Each of these locations can have different sources of poor air quality, and different actions that could be taken to improve the air quality. Examples of some common consumer products that could benefit from an indoor air-quality sensor are shown in Figure 4.

4. These consumer products could benefit from an indoor air-quality sensor.

Bedroom Example

The primary source of air quality in bedrooms is furnishings (especially if carpet or paint is new) and humans. When we breathe, we increase both CO2 and VOCs in the air. A total VOC (TVOC) sensor with optional CO2 correlation would be very useful—the effects of CO2 on our sleep and cognitive function are alarming.3

Objective measurements of sleep quality improve with reductions in CO2, as does performance on tests of logical thinking skills. With the information provided by the sensor, a user could decide to open a window, or open a door to the larger area of the house. HVAC and thermostat-control companies could consider the bedroom a zone to be controlled, not just via temperature, but also via air quality, when people are sleeping.

Kitchen Example

Cooking and cleaning both cause short-term increases in VOC levels, which can sometimes reach quite high levels. This information could be really interesting from a user point of view, in order to understand the effect on air quality from cooking and cleaning activities and choices. The information could prompt user actions, such as opening windows, or manually turning on the kitchen ventilation, or keeping the range hood on for longer amounts of time. The method of sensor operation can be tuned to kitchen odors, and an algorithm to turn a fan on or off, and control ventilation speed would be a very useful tool for appliance manufacturers. A cook’s life would be significantly easier when the range hood can turn on automatically, and turn off once the levels of VOC are decreased.

Office Example

In many ways, an office is similar to a bedroom, in that the biggest contributor to poor air quality is human occupation.4 However, because there can also be different products used (dry erase markers, surface cleaners, dry-cleaned clothing, perfumes), as well as people eating at their desks, the level of both VOC and CO2 can fluctuate throughout the day.

Modern energy-efficient buildings reduce the quality of air by limiting exchanges with outside air, lowering energy costs at the expense of employee comfort and productivity. The use case for an air-quality sensor is somewhat similar to a bedroom, and a sensor that was measuring both VOCs and estimating CO2 would be very helpful. The sensor could be tied into central air-conditioning systems to optimize both energy efficiency and productivity.

The idea of demand-controlled ventilation has been around for many years, but traditional sensors are expensive to buy, implement. and maintain. In addition, individual employees could take control of their comfort and health with personal and portable air-quality detectors and air purifiers.

Debra Deininger is Director of Industrial Sensing at Integrated Device Technology (IDT).

References

1. European Environment Agency, “Indoor Air Quality.” Published April 15, 2013; last modified June 3, Jun 2016. https://www.eea.europa.eu/signals/signals-2013/articles/indoor-air-quality.

2. Fraden, J., Handbook of Modern Sensors: Physics, Designs, and Applications. Springer, San Diego, Calif., USA, 2016

3. “The effects of bedroom air quality on sleep and next-day performance.” Indoor Air, Oct. 2016; 26(5):679-86. doi: 10.1111/ina.12254. Epub 2015 Nov 5. https://www.ncbi.nlm.nih.gov/pubmed/26452168

4. https://hbr.org/2017/03/research-stale-office-air-is-making-you-less-productive

About the Author

Debra Deininger

Director, Industrial Sensing

Debra is the Director of Industrial Sensing at IDT, and was previously the CEO of Synkera Technologies, a gas sensor developer and supplier acquired by IDT in 2016. Debra has over 25 years of experience in gas detection, with a career that has spanned nearly all aspects of the sensor business, including R&D, manufacturing, marketing & sales, strategic planning, and management. Debra has overseen integration of sensors into many different types of products and applications, including life & property protecting facility equipment, process-control equipment, air-quality instrumentation, and personal weight-loss monitors. Her educational background is Analytical and Materials Chemistry.