Download this article in PDF format.

How hard could it be to turn on an LED? Connect the LED in series with an appropriate resistor and hook it up to a dc source with the correct polarity and voilà, instant LED light. Of course, you can do that with a simple LED “pilot” light, but when it comes to lighting multiple LEDs or designing them into homes or vehicles, it’s more of a challenge. As it turns out, efficiency is a big issue. In most cases, the best way to light an LED is to use specially designed linear and/or switch-mode driver ICs.

Sponsored Resources:

- By providing the right topology and features for every LED lighting design

- XDPL8221 Lighting Controller

- XDPL8218 Voltage Flyback IC

LED Lighting Basics

As the technology has progressed, LEDs have gradually replaced incandescent bulbs and CFLs. Increased brightness and lower costs have expedited the changeover from the older lighting technologies. Today, LEDs have found a place in home lighting, automotive, signage, and backlighting for TV sets, video monitors, laptops and tablets, as well as smartphone screens. Simply put, LED lighting has become the dominant method of lighting.

Most LED lighting applications require multiple LEDs to achieve the brightness levels demanded. LEDs may be connected in series, parallel, or some combination. A series connection is usually the best arrangement, as there’s only one current path that’s shared by all of the LEDs, making their illumination the same. In most cases, a series connection is the easiest to implement and troubleshoot. The downside is that if one LED fails (opens), the entire string goes dark.

A parallel connection provides the same voltage to all LEDs. The current in each LED should be the same, but production differences can make the same model LEDs have slightly different currents and brightness levels. The parallel approach isn’t the preferred solution. However, when a large array of LEDs is needed in applications like backlighting and signs, a combination series-parallel arrangement is common. The voltage across each series string in parallel must be exactly the same to prevent current hogging.

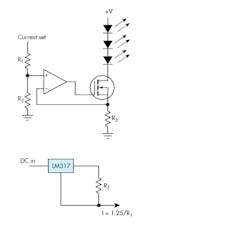

The best way to turn on an LED is to use a current source. This is especially critical when lighting multiple LEDs, usually connected in series. The brightness is a function of current and to have a consistent coherent light source, all LEDs need to be the same brightness. A constant current driver is the solution. Figure 1 shows a couple of legacy examples.

1. Typical constant current sources: An op amp driver for a MOSFET (top); and using a popular three-terminal linear IC regulator like the LM317 as a current source (bottom).

In the top of Figure 1, a MOSFET is the constant-current source driven by an op-amp circuit that sets and controls the current. The bottom of Figure 1 shows how a popular three-terminal regulator like the LM317 can be configured as a constant-current source. The output current is set by the value of R1 and can be anywhere in the 10-mA to 1.5-V range. Such solutions are still viable, but today sophisticated IC LED drivers are available to simplify the application.

A common need in LED lighting is dimming or brightness variation; generally, home-lighting systems and products offer a dimming feature. Multiple methods have been developed to control brightness. Perhaps the most effective is pulse-width modulation (PWM), where a high-frequency rectangular wave signal controls the average current in the LEDs. By varying the duty cycle of the driving wave, brightness can be precisely controlled.

Finally, when a large number of LEDs are used, heat and efficiency become a concern. As a result, linear constant-current driving methods are often unacceptable. The solution has been to develop switch-mode driver circuits that provide not only adequate power, but also high efficiency. The related good news is that a wide range of switch-mode LED drivers are available for virtually all applications.

One company that offers an extensive line of LED drivers is Infineon, and that includes multiple variations of both linear and ac-dc and dc-dc LED switching drivers to address virtually all applications. Some unique applications include LED strips, horticultural, and smart street lighting. In addition, Infineon’s global lighting team supports lighting customer-vendors in designing new LED lighting products and systems.

Sampling the Product Line

To help meet today’s lighting needs, Infineon offers an array of topologies and features to address all types of LED lighting designs. Some of its high-performance LED drivers include:

BCR601 Linear LED Driver

The BCR601 uses an external N-channel MOSFET or NPN bipolar transistor to deliver and control the current to an LED string. A key feature of the BCR601 is active headroom control that improves the efficiency of the IC. The IC monitors the output and provides feedback to an ac-dc supply by way of an optocoupler. As a result, the headroom for proper operation is reduced to its lowest possible value, thereby boosting efficiency. The BCR601 usually gets its dc input from a separate ac-dc supply such as the XDPL8218.

XDPL8218 Voltage Flyback IC

The XDPL8218 implements an ac-dc flyback switching regulator. It includes power factor correction (PFC) and a secondary-side regulator for a solid constant-voltage output. This IC usually works with Infineon’s CoolMOS P7 power MOSFETs. With dozens of configurable parameters that are easily adjusted with the XDPL8218 GUI, users can design more efficient, reliable, and differentiated LED supplies. Typical efficiency is greater than 90%.

XDPL8221 Lighting Controller

The XDPL8221 Lighting Controller, a cost-effective dual-stage driver with advanced features and configurable parameters, is flexible enough to accommodate almost any LED driver’s need. The IC uses a flyback-topology switching circuit to achieve efficiency up to 90%. It features PFC, low harmonic distortion, and adaptive temperature protection. Dimming uses PWM control.

The XDPL8221 also includes a standard UART serial interface that permits connection to an external microcontroller, wireless device, or sensor. This makes it possible to monitor the performance of the IC and control the device output. One-time programmable (OTP) memory lets the designer set the electrical parameters of the device.

LITIX Automotive LED Drivers

LITIX linear ICs use a constant-current regulator to stabilize LED brightness over a wide range of variations encountered in a vehicle, such as battery/system voltage and extreme temperatures.

The LITIX family of auto LED drivers are dc-dc converters that feature one to three outputs, each capable of delivering 120 mA of constant current. Dimming is by way of PWM and an enable (EN) input provides easy off-on control. Output current is set by an external resistor. Built-in protection features are included for overvoltage, noise spikes, and ESD, which often crop up in a vehicle’s hazardous environment. The LITIX devices also have integral diagnostic capability. Versions of the LITIX ICs are available for headlights, taillights, and interior lighting.

An Application

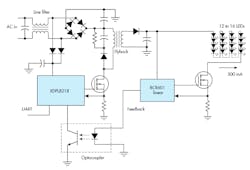

Figure 2 shows a highly recommended application of a two-stage driver that uses a XDPL8218 digital flyback controller in combination with a BCR601 linear LED driver. It offers the constant-current output required by the LEDs, as well as a full switch-mode controller that brings efficiency to the circuit.

2. Here, a simplified LED driver uses a digital flyback controller in a dual-stage combination with a linear driver to maximize the efficiency and other benefits for LED control.

The XDPL8218 gets its input from the ac line and incorporates PFC. This IC operates a flyback converter that powers the BCR601 linear driver and LEDs. The BCR601 uses an external MOSFET to power the LED array. A key feature of this circuit is the feedback from the linear driver by way of the optocoupler. This allows the controller to minimize headroom in the linear output to maintain the highest possible efficiency.

Sponsored Resources:

- By providing the right topology and features for every LED lighting design

- XDPL8221 Lighting Controller

- XDPL8218 Voltage Flyback IC

Related Resources:

About the Author

Lou Frenzel

Technical Contributing Editor

Lou Frenzel is a Contributing Technology Editor for Electronic Design Magazine where he writes articles and the blog Communique and other online material on the wireless, networking, and communications sectors. Lou interviews executives and engineers, attends conferences, and researches multiple areas. Lou has been writing in some capacity for ED since 2000.

Lou has 25+ years experience in the electronics industry as an engineer and manager. He has held VP level positions with Heathkit, McGraw Hill, and has 9 years of college teaching experience. Lou holds a bachelor’s degree from the University of Houston and a master’s degree from the University of Maryland. He is author of 28 books on computer and electronic subjects and lives in Bulverde, TX with his wife Joan. His website is www.loufrenzel.com.