Most integrated circuits are implemented on flat, rigid substrates. Sealed, rigid enclosures ranging from plastics to ceramics typically protect these ICs. As a result, system design becomes even more challenging for applications like wearable electronics as well as other applications that require flexibility.

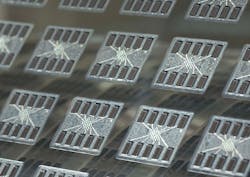

Flexible integrated circuits exist commercially, but they tend to be much more limited than conventional ICs that house billions of transistors. A number of companies have worked to extend their printable storage technology, such as Thin Film Electronics (see “Printable Storage Arrays”) with its Thinfilm Addressable Memory (Fig. 1). Xerox Printed Memory uses this technology to implement a 36-bit writable memory. It targets identification systems including storing lot codes, serial numbers, expiration dates, and geographic codes. Thinfilm Addressable Memory can address counterfeiting as well.

1. Thin Film Electronics ASA is delivering printable storage technology now in the form of Thinfilm Addressable Memory. The technology is used in Xerox’s Printed Memory.

Researchers at Michigan State Univ. have developed a stretchable display (Fig. 2) that combines printed OLEDs and transistors (see “Is a stretchable smart tablet in our future?”). The system uses inkjet printer technology to deposit the display onto a flexible substrate.

This flexible smart fabric is constructed from several nanomaterials and organic compounds. These compounds are used to produce different electronic inks. The team will need another year or two to combine the circuit and display technology into a single device.

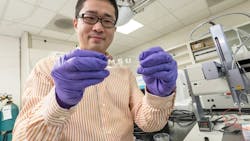

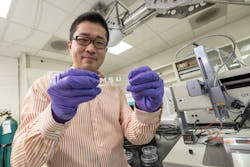

2. Chuan Wang, assistant professor of engineering at Michigan State Univ., shows a stretchable electronic material that he developed with his research team. (Photo by Kurt Stepnitz)

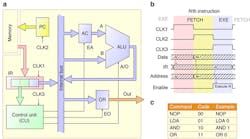

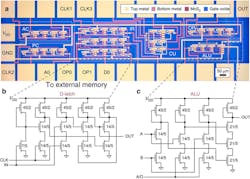

At Vienna University of Technology in Austria, engineers developed a complete microprocessor (Fig. 3) using a molybdenum-disulfide (MoS2) FET semiconductor. The system is built on a substrate that simply acts as a carrier medium. This allows it to be replaced by flexible materials.

3. Vienna University of Technology engineers created a 1-bit microprocessor that implements this architecture using molybdenum-disulfide semiconductor technology.

Of course, it’s only a 1-bit microprocessor implemented with just 115 transistors (Fig. 4), but it can be scaled to larger designs. The device uses a Harvard architecture and memory is off-chip. The system was tested using a number of small applications running at 50 Hz. The speed was limited by the measurement setup.

Fabrication and material development continues forward. Storage capacities and performance are unlikely to match conventional electronics. However, they don’t need to even come close to support sufficiently interesting applications.

4. The Vienna University of Technology chip implements the 1-bit microprocessor using only 115 transistors.

Flexible displays are already a reality. For instance, E ink’s electrophoretic e-paper technology, used in e-readers, is already flexible (see “Designing Low-Power Displays for the Battery-Powered IoT”) and requires no power to maintain an image. Color versions are also commercially available.

Likewise, we see OLEDs arriving into the marketplace (see “What’s the Difference Between TV Display Technologies?” on electronicdesign.com). They provide faster response time than e-paper, but use more power. In both cases, conventional semiconductor chips comprise the drive and display electronics.

To gain a deeper understanding about the technology, you may want to consider attending the Printed Electronics USA show this year in Santa Clara. It addresses a range of topics related to printed electronics, from 3D printing to materials and energy harvesting.

About the Author

William G. Wong

Senior Content Director - Electronic Design and Microwaves & RF

I am Editor of Electronic Design focusing on embedded, software, and systems. As Senior Content Director, I also manage Microwaves & RF and I work with a great team of editors to provide engineers, programmers, developers and technical managers with interesting and useful articles and videos on a regular basis. Check out our free newsletters to see the latest content.

You can send press releases for new products for possible coverage on the website. I am also interested in receiving contributed articles for publishing on our website. Use our template and send to me along with a signed release form.

Check out my blog, AltEmbedded on Electronic Design, as well as his latest articles on this site that are listed below.

You can visit my social media via these links:

- AltEmbedded on Electronic Design

- Bill Wong on Facebook

- @AltEmbedded on Twitter

- Bill Wong on LinkedIn

I earned a Bachelor of Electrical Engineering at the Georgia Institute of Technology and a Masters in Computer Science from Rutgers University. I still do a bit of programming using everything from C and C++ to Rust and Ada/SPARK. I do a bit of PHP programming for Drupal websites. I have posted a few Drupal modules.

I still get a hand on software and electronic hardware. Some of this can be found on our Kit Close-Up video series. You can also see me on many of our TechXchange Talk videos. I am interested in a range of projects from robotics to artificial intelligence.