Keep Those Wearable Technology Power Budgets Lean And Mean

Visitors to Munich's enormous TechFest, AKA Electronica 2014, will have to be pretty fit to stand any chance of getting around a show that has approximately 2700 exhibits.

So given that strenuous challenge, a visit to one of the show's booths displaying the latest in wearable medical related electronic products that can check and monitor your health could prove very pertinent.

The wearable medical market is already recognized as a booming sector with analysts predicting that by 2016 the global market will see the sale of just over 100 million devices

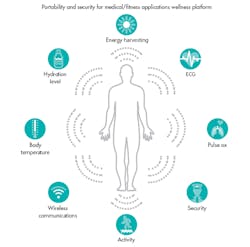

At the show a new Wellness Platform developed by Maxim Integrated Products will be displayed (Fig 1). This is a suite of design hardware and software that according to the company will assist electronics designers to optimize wellness device performance and also cut research and development costs

There is no doubt that wearable medical and fitness devices will not only help people to live healthier lives but will also greatly assist the remote monitoring of patients who have serious chronic illnesses.

At the heart of the Wellness Platform is the MAX32600, a highly integrated ARM Cortex-M3 low-power microcontroller with high-precision analog performance. Its integrated Trust Protection Unit provides the a good level of security with onboard public key authentication, data encryption and tamper detection. This is important because it will help to ensure data cannot be compromised. Recent reports have shown that some wearable electronics with insufficient integrated security are prone to hacking, particlularly if using Bluetooth communication technology.

Requiring minimal discretes, the onboard configurable analog front-end (AFE) of the microcontroller includes high current LED drivers and facilitates one or more wellness metric measurements, such as heart rate monitoring (HRM) and galvanic skin response (GSR). The MAX32600 is available in 192-ball, 12mm x 12mm ChipArray Thin Core Ball Grid Array (CTBGA), 120-ball, 7mm x 7mm CTBGA, and 108-ball wafer-level packaging.

What It Can Find Out About You

The Wellness Platform is designed with several body measurements in mind, all of which will be exhibited as demonstration examples at Electronica 2014.

The Wellness Watch, co-developed with Logic PD, is a low-power watch incorporating several components from the platform. It allows users to monitor heart rate, oxygen level, movement, position, temperature, and mood response.

The Pulse Oximetry Patch measures blood oxygen content and the company's Fit 2 Shirt, which communicates over a Bluetooth connection, measures electrocardiogram response, blood pressure, temperature, blood oxygen content, heart rate and activity level. Maxim Integrated say it is smaller, more accurate, more secure, and has a longer battery life than its previous generation of fitness shirts.

The NFC Temperature Patch, featuring the MAX66242 DeepCover Secure Authenticator chip, is a passive NFC tag that remotely measures temperature while using energy harvesting as the power source. Energy harvesting is a particularly important design advantage when it comes to wearable electronic products although battery technology will still be relied on to support certain products. The Wellness Platform does include the MAX14676 which is a tiny power and battery management solution.

Included as part of the Wellness Platform design programme a Product on Module (PoM) board and a separate application board with medical wellness sensors is being created using components from the Wellness Platform. This board will program the ARM microcontroller, configure built-in analog peripherals, operate with built-in security, drive the RF links and sensors, and manage the system power.

Ultra Low Power IoT Platform

So efficient low power technology coupled with capable communications are essential design elements for wearable products.

Accordingly Taiwanese foundry TSMC has just launched the foundry’s first ultra-low power technology platform aimed at a range of connectivity applications for the Internet of Things (IoT).

TSMC’s ultra-low power process lineup expands from the existing 0.18-micron extremely low leakage and 90-nanometer ultra low leakage nodes and 16-nanometer FinFET technology to new offerings of 55-nanometer ultra-low power (ULP), 40ULP and 28ULP, which support processing speeds of up to 1.2GHz.

The wide spectrum of ultra-low power processes from 0.18-micron to 16-nanometer FinFET is suitable for a variety of smart and power-efficient applications in the IoT and wearable device markets.

Compared with their previous low power generations, TSMC’s ultra-low power processes cut operating voltages by 20% to 30% to lower both active power and standby power consumption and enable significant increases in battery life by 2X to 10X when much smaller batteries are demanded in IoT/wearable applications.

A valuable advantage offered by TSMC’s ultra-low power technology platform is that engineers can use TSMC’s existing IP via the Open Innovation Platform. Designers can re-use IPs and libraries built on TSMC’s low-power processes for new ultra-low power designs to boost first-silicon success rates and to achieve fast time-to-market product introduction. Some early design projects with customers using 55ULP, 40ULP and 28ULP nodes are scheduled in 2014 and risk productions are planned in 2015.

About the Author

Paul Whytock Blog

European Editor

Paul Whytock is European Editor for Penton Media's Electronics Division. From his base in London, England, he covers press conferences and industry events throughout the EU for Penton publications and its Engineering TV and Radio services Qualified to HNC Full Technological Certificate standard, Whytock trained as an automotive design engineer with Ford Motor Company prior to entering technical journalism.