This article appeared in Microwaves&RF. It is reprinted here with permission.

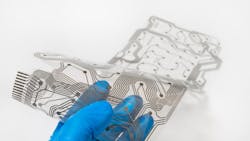

The U.S. Department of Defense (DoD) has much interest in physical flexibility in electronic designs, to the extent that the DoD has made healthy investments in electronic innovator NextFlex. These investments include a recent $154 million award for an Army-led flexible electronics project. Formed in 2015, NextFlex is a consortium of companies, academic institutions, nonprofit organizations, and government organizations with a shared goal of advancing the U.S. position in flexible hybrid electronics (FHE) technology. The list is long and impressive, and includes Analog Devices, BAE Systems, Raytheon Technologies, WL Gore & Associates, Purdue University, and the University of Maryland.The need for durability in the field versus mechanical shock and vibration is clear for many electronic devices, and flexibility built into components such as power supplies and display screens can make a difference in operating lifetimes for many devices. NextFlex is pursuing the development of flexible hybrid electronics (FHE) rather than conventional flexible circuits, with FHE combining printed circuits and components with discrete devices, such as silicon CMOS-based microprocessors and memory (see the figure). FHE technology is a viable candidate for many different types of wearable military electronic health monitors. It is also projected to have tremendous potential for a wide range of commercial electronic applications.

Phase is an important electrical parameter in many military electronic systems, and the phase behavior of FHE-based designs must be studied before the technology can be applied to critical electronic designs. The phase will vary with flexure but, by combining rigid integrated circuits (ICs) and printed circuits on flexible substrates, it is hoped that variations can be minimized and that FHE technology can be applied extensively to durable military electronic devices.

The NextFlex Manufacturing Innovation Institute works with the U.S. Army Combat Capabilities Development Command’s Army Research Laboratory (ARL) and entered into a second cooperative agreement with the U.S. Air Force Research Laboratory (AFRL). As part of the agreements, NextFlex attempts to commercialize FHE prototype circuits developed for the military as part of efforts to establish U.S. leadership in the technology.

“Flexible hybrid electronics is a new way to manufacture electronics that brings together digital additive manufacturing with traditional electronic components,” said Dr. Eric Forsythe, an Army physicist and government program manager for NextFlex. The FHE technology is projected to provide many advantages for future communications and sensor designs in command, control, communication, computers, cyber, intelligence, surveillance, and reconnaissance (C5ISR) systems.

About the Author

Jack Browne

Contributing Editor

Jack Browne, Technical Contributor, has worked in technical publishing for over 30 years. He managed the content and production of three technical journals while at the American Institute of Physics, including Medical Physics and the Journal of Vacuum Science & Technology. He has been a Publisher and Editor for Penton Media, started the firm’s Wireless Symposium & Exhibition trade show in 1993, and currently serves as Technical Contributor for that company's Microwaves & RF magazine. Browne, who holds a BS in Mathematics from City College of New York and BA degrees in English and Philosophy from Fordham University, is a member of the IEEE.