Unique Filament, Nozzle Yield 3D-Printed Optoelectronics

You’re undoubtedly familiar with what’s popularly known as “3D printing” using a variety of solidified, extruded plastic and metal filaments to fabricate unique shapes and objects. But what if the filaments could be more than just structural elements and become embedded functioning optoelectronic sources and receptors? That’s what a team based at MIT has done, opening new options for both “playful” structures as well as potentially very useful ones.

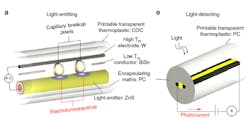

Rather than use single-material fibers, their approach extrudes a filament with a complex internal structure made up of different materials arranged in a precise configuration, all surrounded by a polymer cladding (Fig. 1). These internal components in the filament included metal wires to serve as conductors, semiconductors for active functions, and polymer insulators to prevent wires from shorting to each other.

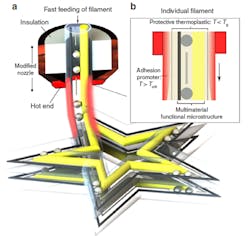

Although the 3D printer was a standard fused-deposition-modeling (FDM) unit, their custom nozzle is designed to operate at a lower temperature than standard 3D-printing nozzles while pulling the filament through faster. As a result, the outer layer of the multi-element fiber gets partially molten and the interior stays cool and solid—filament-created embedded electronic functions are unaffected. The surface of the filament melts just enough to make it adhere solidly to adjacent filaments during the printing process, to produce a sturdy 3D structure.

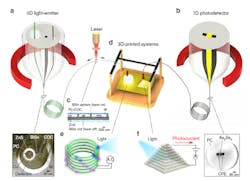

The filaments, which are structured by material and design for light emission and detection, are printed into fully connected 3D serpentine and spherical sensors (Fig. 2). The sensors are capable of spatially resolving light at micron-level dimensions across their centimeter-scale surface.

To make the fibers themselves, the constituent materials are initially assembled into a larger-scale version called a preform. The preform is then heated and drawn in a furnace to produce a very narrow fiber that contains all those materials, in their same exact relative positions but greatly reduced in size (Fig. 3).

As a tangible and vivid demonstration, the team produced a model-airplane wing with embedded LEDs using a filament with eight different materials (Fig. 4). MIT doctoral student and team member Gabriel Loke noted that until very recently, “a printer capable of depositing metals, semiconductors, and polymers in a single platform still did not exist, because printing each of these materials requires different hardware and techniques.”

The work is described in detail in their readable paper published in Nature Communications, “Structured multimaterial filaments for 3D printing of optoelectronics, ” Supplementary Information, and a 20-second video “3-D Printing of Photodetecting Pyramid.” The project was partly supported by the National Science Foundation, the U.S. Army Research Laboratory and the U.S. Army Research Office through the Institute for Soldier Nanotechnologies.

About the Author

Bill Schweber

Contributing Editor

Bill Schweber is an electronics engineer who has written three textbooks on electronic communications systems, as well as hundreds of technical articles, opinion columns, and product features. In past roles, he worked as a technical website manager for multiple topic-specific sites for EE Times, as well as both the Executive Editor and Analog Editor at EDN.

At Analog Devices Inc., Bill was in marketing communications (public relations). As a result, he has been on both sides of the technical PR function, presenting company products, stories, and messages to the media and also as the recipient of these.

Prior to the MarCom role at Analog, Bill was associate editor of their respected technical journal and worked in their product marketing and applications engineering groups. Before those roles, he was at Instron Corp., doing hands-on analog- and power-circuit design and systems integration for materials-testing machine controls.

Bill has an MSEE (Univ. of Mass) and BSEE (Columbia Univ.), is a Registered Professional Engineer, and holds an Advanced Class amateur radio license. He has also planned, written, and presented online courses on a variety of engineering topics, including MOSFET basics, ADC selection, and driving LEDs.