Tiny 60-GHz Motion Detector Challenges PIR Approach

Many close-proximity motion detectors use the classic, widely available passive-infrared (PIR) approach, which is effective but has limited sensitivity and adjustability, and can’t “see” through non-metallic materials. The BGT60LTR11AIP developed by Infineon Technologies AG intends to change that by offering improved movement sensitivity and directivity via its miniaturized 60-GHz radar with embedded antenna. Announced at “electronica virtual 2020,” Infineon maintains that this is a cost-effective replacement for conventional PIR sensors for low-power or battery-powered applications.

Dubbed the XENSIV radar sensor, it can be integrated into such systems to “wake” them up or put them to sleep or auto-lock when no motion is detected for a defined amount of time. It can also trigger other functions based on motion or direction of motion detection. Applications go beyond the obvious of alarm and security systems and cameras to include smart-home devices like thermostats, smoke detectors, kitchen appliances, lighting systems, and other “wake-up” scenarios.

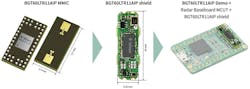

The BGT60LTR11AIP MMIC, a fully integrated microwave device measuring 3.3 × 6.7 × 0.56 mm, operates as a Doppler-based motion sensor (Fig. 1). It includes antennas in package (AIPs) with an 80-degree field of view as well as integrated detectors for motion and direction of motion. Adjustable performance parameters include detection sensitivity, hold time, and frequency of operation, and unlike many 60-GHz devices, it can use standard, low-cost FR4 circuit-board material.

An internal state machine enables operation of the device in an autonomous mode without any external microcontroller, providing digital outputs indicating motion and direction of the target. In this mode, it detects a human target at up to five meters with power consumption of less than 5 mW.

Furthermore, for experienced radar users, the MMIC also supports semi-autonomous and SPI modes where raw data is available and can be extracted for signal processing on a PC or an external MCU. This sampled radar data could be used to develop customized algorithms, and a 10-meter detection range is possible with less than 2 mW power consumption.

Since a device such as this usually needs designer evaluation, Infineon also offers a demo arrangement that includes the BGT60LTR11AIP “shield,” as well as the Infineon Radar Baseboard MCU7 (Fig. 2).

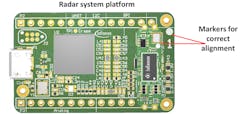

The shield demonstrates the features of the BGT60LTR11AIP MMIC and gives the user a “plug and play” radar solution. It’s optimized for fast prototyping of designs and system integration as well as initial evaluation of features and functions. The shield measures 20 × 6.25 mm and includes an option to solder onto other PCBs such as an Arduino MKR board or an Infineon Radar Baseboard MCU7 for extra flexibility (Figs. 3 and 4).

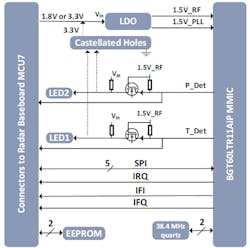

As noted, the PCB can use standard FR4 laminate because the antennas are integrated into the chip package. The bottom side of the shield has the connectors to the Radar Baseboard MCU7, and the castellated holes on the edges of the shield PCB provide additional access to the detector outputs and power-supply signals of the shield (Fig. 5). By using these holes, the BGT60LTR11AIP shield can be soldered onto other PCBs.

Note: Castellated holes are indentations created in the form of semi-plated holes on the edges of the PCBs; they help to mount one PCB board on top of another during assembly (see the Reference below).

Infineon also provides extensive documentation for this product, including:

- AN599, “Radar baseboard MCU7: 60 GHz radar system platform” (23 pages)

- AN608, “BGT60LTR11AIP shield: 60 GHz radar system platform” (21 pages)

- AN625, “User’s guide to BGT60LTR11AiP: 60 GHz radar” (48 pages)

The radar demo kit BGT60LTR11AIP can be ordered now, while the single chip will be available in Spring 2021.

Reference

PCB Directory, “What are Castellated Holes on a PCB?”

About the Author

Bill Schweber

Contributing Editor

Bill Schweber is an electronics engineer who has written three textbooks on electronic communications systems, as well as hundreds of technical articles, opinion columns, and product features. In past roles, he worked as a technical website manager for multiple topic-specific sites for EE Times, as well as both the Executive Editor and Analog Editor at EDN.

At Analog Devices Inc., Bill was in marketing communications (public relations). As a result, he has been on both sides of the technical PR function, presenting company products, stories, and messages to the media and also as the recipient of these.

Prior to the MarCom role at Analog, Bill was associate editor of their respected technical journal and worked in their product marketing and applications engineering groups. Before those roles, he was at Instron Corp., doing hands-on analog- and power-circuit design and systems integration for materials-testing machine controls.

Bill has an MSEE (Univ. of Mass) and BSEE (Columbia Univ.), is a Registered Professional Engineer, and holds an Advanced Class amateur radio license. He has also planned, written, and presented online courses on a variety of engineering topics, including MOSFET basics, ADC selection, and driving LEDs.