Download this article in PDF format.

Japan is a small, island nation, but its efforts in electronic waste recycling are attracting international attention. Could the United States learn from the Japanese model? With a population of more than 127 million, Japan recycles more than 2 million tons of electronic waste annually. America only recycles about 679,000 tons annually, and that figure doesn’t include a large portion of electronics such as televisions, DVD and VCR players, and related TV electronics, per the U.S. Environmental Protection Agency (EPA).

In the States, E-waste represents 2% of America’s trash in landfills, but 70% of overall toxic waste. In fact, according to the EPA, E-waste is still the fastest growing municipal waste stream. Not only is electronic waste a major environmental problem, it contains valuable resources that could generate revenue and be used again. Cell phones and other electronic items contain high amounts of precious metals, such as gold and silver. Americans dump phones containing more than $60 million in gold and silver each year!

The Japanese model has also attracted the attention of Russia, as this nation seeks to launch more significant national recycling efforts. President Vladimir Putin is calling 2017 “The Year of Ecology,” and has stated that improved recycling is a top priority. In fact, Russia hosted the 2nd Congress of Eurasian WEEE Solutions in Moscow this past March.

The Congress, which is part of the Moscow International Recycling Expo, is a platform where those in the Eurasian Economic Union (EAEU) are able to discuss opportunities, solutions, and challenges within the recycling industry, as well as network and develop relationships with recyclers, producers, scientists, regulators, and municipalities, among others key to the industry. The EAEU, which is comprised of the Russian Federation, Belarus, Kazakhstan, Kyrgyzstan, and Armenia, is one of the fastest-growing recycling markets, generating more than 1,500,000 tons of WEEE annually.

Given Japan’s success, and key interest by nations such as Russia, might it not be time for the U.S. to consider other options when it comes to E-waste?

How the Japanese Model Works

In Japan, the electronic waste comes from a number of sources. East Asia is major consumer of electronics and electric appliances, so with each upgrade, millions of outdated models are discarded on a yearly basis. The region also controls a major global share of the import and export of these same products. In addition, trade in electronic waste has been booming in recent years. All of these waste streams combined have raised questions about their potential environmental impacts, and it is these concerns that led Japan to take some significant steps in addressing the issue—and much sooner than most other developed nations.

Japan had already begun to look at the big picture, in terms of electronic waste disposal, back in the early 1990s when they became the first country to enact a law specifically concerning electronic waste. Four factors were behind this legislation:

1. Recognition of the difficulty of disposing of electronic waste compared to other kinds of waste.

2. A major shortage of landfill sites, and concerns about the contamination of soil, groundwater, and other resources.

3. Growing awareness of the benefits of recovering and utilizing the valuable resources contained in electronic waste.

4. The willingness to develop recycling companies as a “venous industry,” a Japanese term for businesses that turn solid industrial waste back into raw materials that can then be used anew.

The groundbreaking Home Appliance Recycling Law went into effect in 1991, and was designed to specifically help control the illegal dumping of items such as televisions, refrigerators, air conditioners, and washing machines. It addressed electronic waste on a number of fronts.

First, the law identified key products that could be targeted for mandatory recycling, such as those which were difficult for local governments to recycle, as well as those containing significant quantities of recyclable resources (e.g., metals) that are inexpensive to recover. It also noted products that could be easily recycled by consumers if they returned them to retailers upon the purchase of replacements. In addition, the law focused on products that could be made more recyclable with certain design modifications.

In 2000, Japan expanded its recycling mandates with the Basic Act on Establishing a Sound Material-Cycle Society, and the addition of its “manifest system.” This system seamlessly tracks waste from the time it leaves the facility where it was produced until it reaches an off-site waste-management facility. At this time, no other country has such a “cradle to grave” tracking system. Not only does this system ensure that materials aren’t disposed of wastefully or illegally, it also clearly outlines the responsibilities of all stakeholders involved in each part of the process.

The role of the consumer, in terms of their recycling responsibilities and how they cooperate with retailers and local governments, is clearly defined as well. Japan has different laws for different products, with some requiring compulsory recycling and others falling under voluntary initiatives.

In recent years, additional laws have continued to refine Japan’s recycling efforts and give them a strong legal mechanism for enforcing the recycling of electronic waste. In addition to the aforementioned products, personal computers and mobile phones are marked for recycling. All of these products combined make up 40% of Japan’s electronic waste.

Japan was also one of the first countries worldwide to implement an Extended Producer Responsibility-based system for electronic waste. This has been modeled on its solid-waste-management system, and has an advanced take-back system and processing infrastructure.

Given the extent of government regulation regarding the recycling of electronic waste, it’s interesting to note that Japan’s rules don’t encompass the process of acquiring a recycling facility or how the recycling is done. Manufacturers can hire anyone they want to build the facility, select the equipment and technology they prefer, and process the waste as they see fit. The only government requirement they must meet is the amount of utilization required from each material that comes into their facility. Manufacturers often want to recycle in the least expensive way possible, which can be less efficient and result in less useful or valuable end products. Japan’s regulations ensure that recycling yields the best possible results.

Currently, local governments collect electronic waste not subject to replacement purchase from consumers and transport these materials to collection centers run by the producers. Depending on the items purchased, and the circumstances, consumers may also pay retailers to pick items up—if the consumer has purchased a replacement item, then the retailer automatically picks up the older item. Consumers help bear the burden of recycling costs via fees that are levied on goods as they’re turned in for recycling. Retailers and distributors also pay fees.

In 2001, Japan implemented the Law for the Promotion of Effective Utilization of Resources, which requires manufacturers to recycle goods and reduce the generation of waste.

According to the Association for Electric Home Appliances (AEHA), as a result of these laws and regulations, in 2013, 556,000 tons of electronic waste were officially collected and treated in Japan—that’s roughly 24% of the electronic waste generated for that year.

Technology Plays a Vital Role

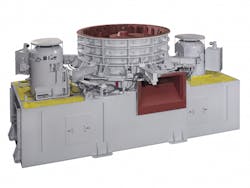

The advent of sophisticated recycling technology has played a major role in the success of Japan’s electronic-waste recycling program. Japan has approximately 100 major electronic waste facilities, as well as numerous smaller, local collection and operating facilities. Out of the 100 major plants, more than 30 utilize the Kubota Vertical Shredder to reduce the size of the electronic waste. With the Vertical Shredder holding roughly 30% of the market share, it’s clearly the preferred choice of electronic-waste operators. In fact, Kubota has long dominated the Japanese market, and has been selling this shredding technology to the recycling industry for more than 40 years.

The Kubota Vertical Shredder is widely used to grind down electronic waste into various particle sizes.

The mighty Kubota Vertical Shredder can process large and small domestic appliances, metal scrap, and other bulky items, thanks to some unique features that make it indispensable to the recycling industry. It breaks down and grinds up materials down to one inch or less in size in a single pass, and the particle size can easily be adjusted.

The Vertical Shredder can be used as a standalone unit or in combination with other processing technology, which tends to be the most popular option. Close to 400 users have already taken advantage of its powerful breakers and multiple layers of grinders to process a broad variety of waste materials.

swissRTec of Switzerland is a frequent distributor of the Kubota Vertical Shredder technology. The company is a leader in designing, building and commissioning turnkey e-waste, scrap-metal, and ASR (automotive shredder residue) recycling facilities. The company’s core focus is the shredding, delamination, and separation of valuable raw waste materials from waste compound materials.

“More than 40 years of proven technology are built into the Kubota Vertical Shredder,” says Mario Zoellig, CEO of swissRtec. “It is efficient, compact, and does pre-shredding and secondary shredding in a single pass. Output particle size can be as small as one-quarter inch when processing ASR. Most important, choke rings allow for adjustment of particle size—no screens are required. It is designed for continuous operation, is versatile, and very efficient to operate.”

The Kubota Vertical Shredder comes in various models, sizes, and power options to fit the diverse needs of recycling customers, and works well in combination with the swissRTec Delamination Mill. The Delamination Mill is an “impact mill” that uses thousands of collisions to break down pre-shredded composite materials, isolate various components, and then mill them into tiny, smooth balls that are easily separated.

Without such technology, recycling on a large scale, such as that embarked on by Japan and contemplated by Russia, would not be possible or profitable. With efficient recycling systems, for every one million cell phones that are recycled, 35,274 pounds of copper, 772 pounds of silver, 75 pounds of gold, and 33 pounds of palladium are recovered.

“The technology available with the Kubota Vertical Shredder and the swissRTec Delamination Mill meets the operating needs of today’s companies,” says Zoellig. “The shredder provides optimal flexibility for serving various industries, and that, combined with the fine processing capabilities of our Delamination Mill, allows companies to process waste more efficiently. When you recycle, you cannot control your intake—you have to deal with the materials that come your way. But our shredder allows you to better adapt to what comes in, and thus make processing more productive and economical.”

Whether Russia follows Japan’s lead and issues government mandates regarding the recycling of electronic waste, or relies on privatization and entrepreneurship to grow their recycling industry, one thing is clear: Recycling of electronic waste is essential as the problem will only expand not diminish. The bright spot is that with the right technology, it can also be quite lucrative, create essential jobs, and generate new revenue streams.

About the Author

Crystal Ward Kent

Owner and freelance writer

Crystal Ward Kent is a freelance writer based in New Hampshire and the owner of Kent Creative, a writing, design, PR, and marketing firm. She writes on a wide range of topics, but specializes in the environment, energy, and medical fields.

Bernhard Mueggler

President and CEO

Bernhard Mueggler is president and CEO of swissRTec America, a subsidiary of swissRTec International. swissRTec is a builder of recycling systems. Mueggler, a native of Switzerland, has more than eight years of experience in the recycling industry.