TSN: Converging Networks for a Better Industrial IoT

Download this article in PDF format.

Implementation of the Industrial Internet of Things (IIoT) certainly generates its share of challenges, one of the biggest being the convergence of information-technology (IT) and operational-technology (OT) networks. Currently, these networks exist in separate domains—dedicated gateways provide limited communication in each direction. To enable cyber physical systems, though, these networks need to converge, whereby nodes interact with each other using the IIoT.

The current architecture for controlling factory automation is hierarchical. Enterprise resource planning (ERP) applications at the highest level provide an integrated management and automation of business core processes, progressing down to manufacturing execution systems (MES) that control the manufacturing process. Programmable logic controller (PLC) systems execute the automation tasks using connected industrial devices like electric drives, sensors, or I/Os, which reside at the lowest level of the hierarchy.

These levels, as a whole, are often called the “Automation Pyramid” (Fig. 1), illustrating the broad amount of devices at the bottom and high-performance computers at the top. Layers of the pyramid illustrate the hierarchies.

Different layers in the pyramid have different network requirements. While higher layers need high bandwidth and flexible network topologies, lower layers need deterministic behavior and the capability to transport samples in constant intervals with low packet delay variation. This leads to multiple networks that work side-by-side.

The Urge to Converge

A converged network will address several challenges that currently exist in today’s disparate network architecture:

- More transparency: All data from all hierarchies can be made accessible to every element in the factory without translation in between.

- Less network planning: More flexible topologies enable easier changes.

- Less CapEx: Reduction of cabling; reduction of gateways between networks with different protocols.

- Less OpEx: Reduction of network administration effort.

- More bandwidth: Avoid limitation to one network speed.

- Optimized for M2M: Ready for interworking between machines with common data model like OPC UA across the entire factory.

This convergence is provided by time-sensitive networking (TSN). TSN is a set of IEEE 802 sub-standards that, when implemented, enable deterministic communication over Ethernet networks while keeping the benefits of communication in best effort manner, on that same network.

TSN introduces different traffic classes that share the same link. TSN network configuration reserves resources for streams with deterministic time characteristics. TSN, therefore, enables one common network to be implemented that supports multiple communication standards.

Such a network opens the door to several improvements over standard Ethernet. Standard Ethernet communication isn’t time-aware; it distributes the data over the entire bandwidth of the link with packets queued in order for transmission. TSN implements time awareness with scheduled traffic at configured offsets in cyclic intervals. That follows a schedule distributed by a network configuration controller. Further TSN features introduce Filtering and Policing for TSN streams, seamless redundancy, and support for cyclic data transmission, while also providing pre-emption for higher-priority packets.

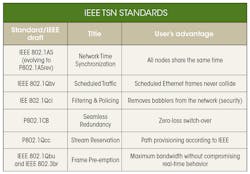

TSN is defined by a set of IEEE 802.1 standards that specify the implementation (see table). As of September 2017, four of these standards are adopted, while the remainder is still within the Task and Working Group stages.

These standards are implemented over Ethernet (IEEE 802.3 Physical layer) and support star, chain, ring and mixed topologies and they are not limited to a specific data rate. Industrial applications will use 100Mbit and 1Gbit data rates mainly. Therefore, TSN provides the convergence between the IT and OT networks. This convergence reduces the cost of implementing the network, significantly lowering the cost of ownership and operation.

TSN Implementation

Proper implementation of TSN requires a solution that can provide a low latency and deterministic response at TSN end points and TSN bridges. Many applications solve this challenge by combining a processor and a FPGA connected over a high-speed link such as PCIe. This two-chip solution not only increases occupied board space, power consumption, development time and cost, but also prevents a holistic integrated solution from being developed. Furthermore, segmenting the design between two devices increases the complexity of verification.

To avoid those issues, providers are opting for alternatives such as All Programmable Zynq-7000 and Zynq UltraScale+ MPSoC devices to implement their solutions. These devices, which combine a processing system (PS) and programmable logic (PL) for the implementation of acquisition, control, and processing applications, introduce:

- The ability to interface and control a wide range of sensors, actuators, motors and other application-specific interfaces.

- The ability to implement complex processing at the edge, e.g., machine learning, sensor fusion, image processing, and real-time analytics.

- Scalability concerning the number of network interfaces.

- Security and the ability for the device and system to be secure in terms of information assurance, anti-tamper, and trust.

The Zynq devices also support any-to-any interfacing and the ability to couple PS and PL.

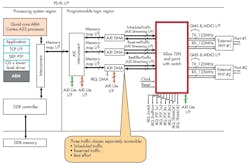

Looking deeper at the systems-on-a-chip (SoCs), they incorporate Xilinx's 1G/100M TSN Subsystem LogiCORE IP, which consists of FPGA logic for MAC, TSN Bridge, and TSN Endpoint. The TSN design with dedicated logic resources guarantees that the timing behavior is strictly deterministic.

Software that runs in the PS is for network synchronization, initialization, and interfacing with network configuration controllers for stream reservation. The software is designed to run on Petalinux and will be published for Yocto builds.

The LogiCORE IP also has an optional integrated time-aware L2 switch that creates the chain or tree topology required in many industrial applications without allocating another port at an external TSN switch. Seamless Redundancy (P802.1CB) also requires the additional port. With the complete IP (Fig. 2), the user can freely configure before synthesis whether or not the switch shall be integrated.

Once instantiated, the TSN IP core provides individual AXI Streaming ports for each traffic class. Scheduled traffic, reserved traffic, and best effort traffic are supported. The AXI Streaming ports connect to infrastructure that’s introduced by Xilinx’s Vivado Design Suite. AXI Lite is used in the configuration of the TSN blocks.

A ready-to-use implementation for evaluation purposes includes direct memory access (DMA) separately for each of the traffic classes. The evaluation system (Fig. 3) can be used to test the behavior between Xilinx components or when combined with third-party equipment or with protocol analyzers.

Since PL is flexible, it also provides the ability to update the IP core as TSN standards and market-segment specific conformance tests progress. On the other hand, devices with fixed hardware implementations (like custom ASICs and application-specific standard products, or ASSPs) lack the option to introduce functional changes along the TSN evolution.

To demonstrate the TSN IP core in action, Xilinx created a demonstration application for both the ZCU102 and ZC702 development boards. Connecting two of these boards (Fig. 4) allows network traffic to be transmitted and received, enabling validation of TSN networking capabilities.

The Industrial Internet Consortium (IIC) offers a TSN testbed (of which Xilinx is a member) with which companies can do vendor interoperability testing, along with testing of high-performance and latency-critical applications. This testing can occur both formally on one of the two permanent testbeds located in either the USA or Europe.

Conclusion

To enable deployment of the cyber physical systems for Industrie 4.0 and IIoT, there needs to be convergence between IT and OT networks. TSN makes it possible to converge these networks, creating significant advantages in network connectivity, scalability, and cost of deployment and ownership. For more information, click here.

About the Author

Adam Taylor

Adiuvo Engineering and Training

Adam Taylor is an expert in design and development of embedded systems and FPGAs for several end applications. Throughout his career, Adam has used FPGAs to implement a wide variety of solutions from radar to safety-critical control systems, with interesting stops in image processing and cryptography along the way.

Most recently, Adam was the Chief Engineer of a space imaging company, being responsible for several game-changing projects. He is the author of numerous articles on electronic design and FPGA design, including over 200 blogs on how to use the Zynq for Xilinx. Adam is a Chartered Engineer and Fellow of the Institute of Engineering and Technology, and is the owner of Adiuvo Engineering and Training, an engineering and consultancy firm.