The recent Siemens PLM World conference in Phoenix included a host of new product announcements as well as innumerable presentations about how product lifecycle management (PLM) is changing everything from design flow to product delivery. One of the keynotes highlighted the idea of personalized production that ties into technologies like 3D printers. Siemens is working with companies like Adidas to generate custom products for each individual. The idea of a perfect fit for shoes, clothes, cars, etc. is a possibility.

This idea reminded me of the book A Mote in God’s Eye (Fig. 1) by Jerry Pournelle and Larry Niven. It’s a science-fiction novel that features a race of aliens nicknamed “moties” that have many specialized subspecies including “engineers.” The engineers have technical abilities while their “watchmakers” can build and customize just about anything, resulting in custom-made solutions for everything from food processors to spaceships.

1. A Mote in God’s Eye, a novel by Jerry Pournelle and Larry Niven, is about humans that discover a race of aliens nicknamed “moties” that have many specialized subspecies, one of which can create custom devices.

Dealing with the moties and their watchmakers proved to be an interesting challenge, but the idea of creating custom solutions for a consumer isn’t unknown, just hard to do in many instances. Typically, a custom solution is often expensive and time-consuming to deliver, making the approach impractical when it comes to the mass market.

Siemens, and other PLM vendors, see PLM technology and technologies such as additive manufacturing to be a way to deliver this type of solution in quantity as well as quality. This also ties into the idea of digital twins and the industrial Internet of Things (IIoT), where devices may be customized for their particular application. This requires not only the ability to create and configure a device, but to manage and support it over time where the device is just one of hundreds or millions.

Continuous Updates

Siemens PLM has a number of major software components, including Teamcenter, Simcenter mechatronics simulation, Capital software, NX CAD software, and Polarion application lifecycle management (ALM) software. New versions and features were announced for each; however, the major change across the board is the move to continuous release.

Continuous release has been done in many other software arenas, such as consumer software where updates are automatic and transparent while version numbers are hidden. The approach has the advantage of getting new features and bug fixes to users more quickly. It can reduce deployment costs since the IT department doesn’t have to continually update software. This approach also provides a more predictable schedule for updates, making planning easier.

The process is actually more complicated for a vendor like Siemens and its customers because this isn’t one product, and many of the software tools involved also support third-party software. Making sure updates across the product line are compatible is critical, but it puts the onus of regression testing on the vendor. Of course, Siemens customers will be able to manage the flow of updates, as finding a problem in the field due to updates can have catastrophic effects for critical projects.

Solid Edge Enhancements

Solid Edge 2019 adds electrical and printed-circuit-board (PCB) design tools to its software suite. There’s also new requirements-management capabilities and fully integrated simulation analysis support. Users will be able to take advantage of secure, cloud-based project collaboration. All of this is designed to improve end-to-end digital-twin design and support.

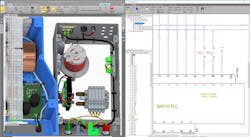

2. The Solid Edge Wiring Design provides design and simulation tools for the rapid creation of wiring diagrams and verification of electrical systems.

The Solid Edge Wiring Design (Fig. 2) is a graphical authoring environment for creating wiring diagrams. It also handles verification of electrical systems. Simulation support can address design challenges such as short and open circuits, voltage drop, fusing, and wire sizing errors.

The Solid Edge Harness Design software adds harness and formboard design tools. These have automated part selection, design validation, and manufacturing report generation. The Solid Edge PCB Design tools provide schematic capture and PCB layout support. They’re all integrated with the mechanical design tools to reduce costly errors.

Solid Edge 2019 also incorporates new modular plant design capabilities, which includes Solid Edge P&ID Design and Solid Edge Piping Design improvements. Solid Edge P&ID provides 2D flow diagram and symbol support that meets strict governing requirements for plant design. The Solid Edge Piping Design has new features such as automated 3D piping design with comprehensive 3D part libraries and fully automated isometric drawing output for plant design.

Furthermore, Solid Edge 2019 offers additional support for the latest additive-manufacturing capabilities: improved control of shapes, weight and strength, and specific factors of safety. It automates print preparation, including multi-color, multi-material printing capability. This reduces the bill-of-materials size and parts inventory, plus it decreases dependency on costly manufacturing equipment. With these new capabilities, manufacturers are able to produce low production lots very quickly and affordably.

About the Author

William G. Wong

Senior Content Director - Electronic Design and Microwaves & RF

I am Editor of Electronic Design focusing on embedded, software, and systems. As Senior Content Director, I also manage Microwaves & RF and I work with a great team of editors to provide engineers, programmers, developers and technical managers with interesting and useful articles and videos on a regular basis. Check out our free newsletters to see the latest content.

You can send press releases for new products for possible coverage on the website. I am also interested in receiving contributed articles for publishing on our website. Use our template and send to me along with a signed release form.

Check out my blog, AltEmbedded on Electronic Design, as well as his latest articles on this site that are listed below.

You can visit my social media via these links:

- AltEmbedded on Electronic Design

- Bill Wong on Facebook

- @AltEmbedded on Twitter

- Bill Wong on LinkedIn

I earned a Bachelor of Electrical Engineering at the Georgia Institute of Technology and a Masters in Computer Science from Rutgers University. I still do a bit of programming using everything from C and C++ to Rust and Ada/SPARK. I do a bit of PHP programming for Drupal websites. I have posted a few Drupal modules.

I still get a hand on software and electronic hardware. Some of this can be found on our Kit Close-Up video series. You can also see me on many of our TechXchange Talk videos. I am interested in a range of projects from robotics to artificial intelligence.