Bob Pease took exception to poor user interfaces. I, too, have railed against poor design that makes a product hard to use. There’s another important aspect to industrial design, and that’s the cost needed to build the product. One problem I saw in the auto business in Detroit was that the designers would carve the car’s exterior and interior in clay, and then it was if it was set in stone. The big bosses had all approved it, and no lowly engineer could complain the design was hard to build.

This could turn into a fiasco. The 1980 pickup truck redesign I worked on had a plastic dashboard. It was justified by management as a cost reduction, but the real reason was that it allowed a snazzier design. The competing pickup had a plastic dash, so the design was seen as a competitive issue. The early prototypes of the dashboard were acrylic plastic.

The first crash test showed a major problem. The crash test dummy’s head would shatter the dash on impact. Due to the nature of acrylic plastic, the break would leave long sharp shards of broken plastic around where the head impacted. When the dummy’s head would bounce back, the sharp plastic shards would rip the dummy’s face off. Interestingly, since breaking the plastic absorbed a lot of the crash energy, the dummy did not “die,” it just looked horrible. Juries tend to award lots of money to people with lacerated faces.

Dashed Cost

The company made the expensive decision to replace the cheap acrylic plastic with polycarbonate, or perhaps it was a polycarbonate-ABS blend. This dashboard would not shatter when the crash test dummy’s head hit it. It would bounce the head back, breaking the neck. The new design might kill you, but at least you would have a good-looking corpse. At least dead people don’t sue. The plastic upgrade wiped out the supposed cost reduction for the plastic dashboard.

I should note the old pickup truck model had a dashboard that was steel, covered with a foam pad. This turned out to be ideal for crash protection. The foam pad protected your face from lacerations, while the steel underneath would bend, absorbing the energy from the crash. It did not break your neck or lacerate your face. It also provided structure—the cab was stronger since the dashboard was welded into the cab structure. This led to the next cost penalty, when Belgian block rough-road testing showed we needed to add several steel tube supports so that the plastic dash did not waggle and bob as you went over rough roads. Trucks are supposed to be tough, after all.

The cost penalty for the plastic dash was pretty bad already. That’s when I noticed that the cost assumptions of the electrical group where I worked had not taken into account that the plastic dash meant we had lost all the “free” grounds for electrical devices in the dash. Back then, 18-gauge wire was a penny a foot and a penny a termination. That was bad enough for the radio and other devices, but it really got expensive for the heavy-gauge ground needed for the cigarette lighter. Now the pretty stylish dash loved by the industrial designers was turning into a serious cost penalty.

I should note that an engineer’s job in the old auto business was not to design cars. That was done by the stylists and a bunch of MBA (Masters in Business Administration) types called product planners. Engineers were supposed to make the car cheap. The whiz-kid finance people that had taken over in the 1960s just kept beating on us to make a cheap car. When we did, no one wanted to buy it, and the management was actually surprised. So, an engineer that went five cents over cost targets would have his career sidetracked. If you lost them 50 cents, you would expect to be fired.

Tone-Deaf High-Volume Design

1. The Bose Lifestyle Model 20 stereo from 1996 has a pretty exterior that hides an expensive-to-build nightmare.

A problem occurs when the industrial designers have no concept of modern high-volume manufacturing. I ran into this recently when I fixed an old Bose Lifestyle 20 stereo (Fig. 1). When it came out in 1996 it was a pretty, swoopy, modern design for the times. It has some user interface annoyances. For instance, there’s nothing to tell you that you just pull up on the front cover to make it smoothly swing up to reveal the six-disk CD player and the control buttons (Fig. 2).

2. The front cover swings up, held down by a magnet resisting a damped spring mechanism.

The real sin of the industrial designers was to make the design of this consumer product very hard to build. I think it was similar to the auto business. The shape and locations of the controls and displays were set in stone by some stylist, and the poor engineers were sent in afterwards to make the thing work. I have heard the same thing about the original Polycom conference phones. They were stylish and pretty and looked like a spaceship, but they were very expensive to build.

A friend asked me to fix this Bose stereo. The display was dead, and there were videos on the internet showing how to replace five capacitors in the display power supply to fix it. As my pals say, "It's always a capacitor."

I made my own video of fixing the display:

As I worked on the unit, it became apparent that the industrial designers had no concept of low-cost consumer electronics design. I accept the cost of the spring and damper that made the front cover smoothly swing up; that’s something the user touches and that’s where you should spend some money. What bothered me were design decisions that made the unit not only expensive, but hard to service.

The first hassle was that the metal top was just a thin cover held on with little plastic trees (Fig. 3). There’s nothing to tell you to pry up on the cover with a putty knife to get it off. One of the plastic trees de-bonded from the cover—another service hassle nobody needs.

3. The metal top cover is held on with plastic “trees” that snap into the redundant plastic top cover. The top left tree has come unglued and is still in the base. A copper tab grounds this metal cover for radio-interference reduction.

Next hassle was the dark plastic display cover (Fig. 4). It snapped in, and there was no way to tell how to pry it off without breaking anything.

4. The vacuum-fluorescent display is covered by this dark plastic cover. It snaps in, but there’s no indication how to unsnap it.

In a classic case of silly design, the metal top was just an appearance cover for the real top cover (Fig. 5). Beside two screws, there were little hooks molded into the cover that you had to somehow know to pry back with a small screwdriver to get the cover off.

5. The redundant plastic top cover is held in with two screws and four large molded-in hooks that you have to know how to pry back in order to release the assembly.

The underside of the top cover had the swinging front cover attached (Fig. 6). What was astonishing was the left side of the swinging assembly was not attached to anything. It just flops around, and is captivated when you install the top cover to the base.

6. The underside of the plastic top cover has the swinging front cover attached, but only on one side.

More absurd yet was the small block that was captivated (Fig. 7). It had to be rotated to a certain position. It was easy to put it together with the block 180 degrees out, and then the cover would not assemble on the left side.

7. One side of the swinging front cover is hinged to a small loose block. It must be oriented correctly so that the round portion fits into a recess in the bottom cover. Note the plastic tree that came unglued from the metal cover is still in place.

Electronic “Hydra”

8. The interior of the unit has a six-CD changer on the left, and a complex electronic assembly on the right.

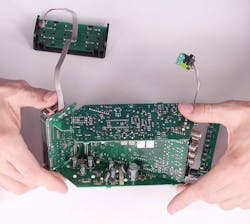

With the top cover off, astonishment gives way to dismay (Fig. 8). The whole left side of the unit is the six-CD changer, and it’s likely a purchased assembly. No problem there, it’s spring-cushioned and lifts out after you disconnect a single ribbon cable (Fig. 9). The dismay comes from the electronics. The main assembly has five printed circuit boards (PCBs). They are soldered together with jumper wire assemblies. Slots in the display board try to align the two vertical boards. One of those boards is the display power supply with the bad capacitors.

9. The CD changer lifts out to show several circuit boards; some snap in, others are captivated with you put the top cover on.

In addition to those five PCBs, there’s a PCB for the buttons, connected with a ribbon cable. Another PCB and ribbon is for a few RCA jacks on the back. The designers caused yet more expense with a little board that just held the headphone jack (Fig. 10). That board also served as an infuriating service puzzle. There was a tiny tab at the bottom you pushed, which let the board rotate about the headphone jack. Then you could pull it out of the lower case. All of these boards had ribbon cables, and near as I could tell, they were not connectorized on either end, unlike the CD changer ribbon cable.

10. The headphone jack is on a little PCB that’s retained by a tiny tab at the base. It’s a real puzzle.

All these dangling parts made the electronics assembly look like some demon Hydra (Fig. 11). The ribbon cables also needed clips and routing features in the case—more expense and hassle.

11. The electronics assembly is incredibly complex and expensive to build.

The underside of this monstrous assembly would reveal the dried-out electrolytic capacitors that needed replacement (Fig. 12). Since the solder-side of the board was facing outward, at least I could use a solder sucker to remove the capacitors.

12. The underside of the electronics assembly shows the problem capacitors that dry out and fail over time. This unit is as complex and hard to work on as a car stereo.

I’m not saying engineers should solely style products so that they are easy to build. Then you end up with what I call “Soviet” design." You should not design a product for the convenience of the engineers, but for the convenience of the customer. Yet there are really good industrial designers that understand the cost implications of their pretty, swoopy CAD (computer aided design) models.

Approaches that Make Cents

Perhaps if the engineers were included in the styling review, they could have shown the kludge-fest of all these circuit boards. Then the stylist could have redesigned things a little more conducive to actually making the product. I have read that 90% of the cost of your product is established in the design phase. Sure, the purchasing agents can beat on the suppliers for a few cents here and there, but most of the cost in this design was dictated by the thoughtless styling.

The methods of low-cost design are well-known. There are concepts like Z-axis assembly, where the product goes together like a cake, with one layer put down on the top of the other. That usually implies you put the top cover down on the bench upside down, toss in a single PCB and a few mechanical components, and then plop down the bottom cover that you screw together with four or more identical-length screws. It’s less a puzzle and much more serviceable. This also means its way cheaper to rework when there’s a problem in assembly or, heaven forbid, a recall.

Coming from the automotive business, perhaps I dwell too much on cost. Yet consumer electronics have even greater cost pressure, so I would expect this high-volume stereo to have better industrial design. Even when I worked at military aerospace companies, cost always mattered. Plus, when it’s simple to design, it’s simple to build—and it’s simple to maintain, and it’s simple to recycle and scrap. Be sure to ask to see those industrial design models in the preliminary stages, so you can give an engineer’s perspective on the cost, service, and reliability aspects. That fancy industrial design contract house might make a pretty design, but they don’t have to live with the cost of putting it together.

About the Author

Paul Rako

Creative Director

Paul Rako is a creative director for Rako Studios. After attending GMI (now Kettering University) and the University of Michigan, he worked as an auto engineer in Detroit. He moved to Silicon Valley to start an engineering consulting company. After his share of startups and contract work, he became an apps engineer at National Semiconductor and a marketing maven at Analog Devices and Atmel. He also had a five-year stint at EDN magazine on the analog beat. His interests include politics, philosophy, motorcycles, and making music and videos. He has six Harley Sportsters, a studio full of musical instruments, a complete laboratory, and a video set at Tranquility Base, his home office in Sun City Center Florida.