Enhanced 0.13-µm BCD Process Targets Auto Power Electronics

In electric drive vehicles, power electronics govern the operation of inverters, converters, on-board chargers, the speed of the motor, the torque it produces, and the performance of other systems in which a unidirectional or bidirectional flow of energy is occurring.

Driven by the steadily increasing adoption of EVs, the global market for power electronics is projected to reach $30.01 billion by 2026, registering a CAGR of 35.5% according to Allied Market Research’s recently published report, "Power Electronics for Electric Vehicle Market (2019–2026).” Overall, IHS Markit technology research, now a part of Informa Tech, predicts the automotive semiconductor sector—including power products—is forecast to grow from $42 billion in 2019 to approximately $60 billion in 2023.

To help designers build competitive power products that can achieve the necessary higher efficiency, reliability and regulation accuracy (as well as reduce BOM costs and time-to-market), MagnaChip Semiconductor, a Korea-based designer and manufacturer of analog and mixed-signal semiconductors, announced a new 0.13-µm BCD (bipolar-CMOS-DMOS) process with improved performance.

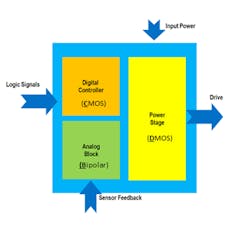

Invented by STMicroelectronics in the mid-1980s, BCD represents a family of silicon processes, each of which combines the strengths of three different process technologies onto a single chip: bipolar for precise analog functions such as signal control, CMOS (complementary metal-oxide semiconductor) for digital design, and DMOS (double-diffused metal-oxide semiconductor) for power and high-voltage elements.

BCD technology, also offered by other vendors including Analog Devices, Bosch Infineon, Reneseas, Texas Instruments, and major foundries like TSMC, brings many advantages to a silicon integrated circuit: improved reliability, reduced electromagnetic interference and smaller chip area footprints.

The product spectrum of the BCD power IC industry is, generally speaking, divided into two areas: high-voltage BCD and high-density BCD. High-voltage BCD enables reliable coexistence on the same chip of low-voltage control circuits and very high-voltage DMOS stages with typical voltage capability up to 800 V. High-density BCD is driven by the need to integrate more complex and diversified functions on the same chip as well as guarantee high quality and reliability in all types of application environments.

Certain end markets, including automotive, require that power ICs are capable of achieving high-temperature reliability and high operational voltages. This is especially the case for EVs and hybrid electric cars, as more 48-V battery systems are adopted to improve fuel efficiency and reduce carbon-dioxide emissions. At the same time, the fast-growing Li-ion battery market for EVs and energy storage is moving to taller battery-cell stacks that require higher voltages.

For this reason, the new MagnaChip process has been certified as Grade-1 under AEC-Q100, a reliability standard for automotive electronics. Therefore, it’s suitable for diverse automotive power semiconductors, including motor-driver ICs, battery-management systems (BMS), and dc-dc ICs used to increase (boost) or decrease (buck) battery voltages to accommodate the voltage needs of motors and other vehicle systems such as lighting and infotainment.

When applied to this newly enhanced 0.13-µm BCD process, MagnaChip’s Multi-Time Programming (MTP) IP enables a chip to be reprogrammed at least 1,000 times, according to the company. This becomes a desirable feature for power semiconductors that require repeatable memory programming, such as motor-driver ICs, power-management ICs, and level-shifter ICs. Also, unlike its previous 0.13- µm BCD method, the new process doesn’t require additional photo layers as a result of IP design optimization. By virtue of no additional layers, MagnaChip's BCD process should allow its customers to shrink cost and time-to-market.

YJ Kim, Chief Executive Officer of MagnaChip, commented: “Along with the rapid growth of the automotive power semiconductor market, demand is rising for foundry technologies with the highest possible reliability and cost competitiveness. Thanks to our BCD know-how and manufacturing expertise, I believe MagnaChip is more than capable to be the leading service provider in the growing automotive power semiconductor market."

With the introduction of this process, Kim adds, the company plans to launch targeted marketing activities to attract more automotive semiconductor designers as customers.