Automotive Digital Quad Isolator First to Meet “Grade 0” Temp Spec—Transceiver Follows Suit

Isolation of digital signals is needed for a wide range of reasons: signal integrity, floating grounds, separating high- and low-voltage signals, and user safety. It’s a requirement in automotive designs that just a few decades ago didn’t need it, or were served by low-speed electromechanical relays that, of course, are inadequate for isolating today’s data links. While there are various all-electronic and thus high-speed options for data isolation, doing so in a small wide-temperature package is definitely a challenge.

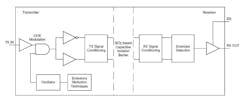

To address these needs, Texas Instruments introduced what it says is the industry’s first digital isolator qualified to the “Grade 0” ambient operating temperature specification of the Automotive Electronics Council (AEC)-Q100 standard. Designed to protect low-voltage circuitry from high-voltage “events” in hybrid-electric-vehicle (HEV) and electric-vehicle (EV) systems, the 100-Mb/s ISO7741E-Q1 quad-channel isolator uses SiO2-based capacitive-coupling techniques to achieve 1.5-kVRMS working voltage with 5000 VRMS isolation ratings per UL 1577 (Fig. 1).

The isolator supports temperatures up to the Grade 0 maximum mandate of 150°C. Thus, it eliminates the need to design and implement additional cooling systems to reduce operating temperatures to below 125°C, which is the maximum temperature that devices qualified only to Grade 1 can support.

The multichannel isolator operates from a wide supply range of +2.25 to 5.5 V, providing level translation between those two voltages. Other electrical ruggedness ratings include up to 12.8-kV surge-withstand capability along with a ±100-kV/μs typical common‐mode transient immunity (CMTI) rating. Power consumption is 1.5 mA per channel at 1 Mb/s while propagation delay is 10.7 ns (both typical) with a 5-V supply.

The comprehensive 34-page ISO7441E-Q1 datasheet provides a full array of static, dynamic, temperature-dependent, and voltage-dependent characterizations and graphs. Despite its fairly high voltage ratings, the device is housed in 10.3- × 7.5-mm, 16-lead SOIC package, and is priced at US$1.49 in 1,000-unit quantities.

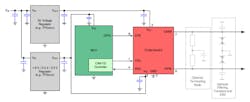

Of course, isolation of a data link alone solves only part of the end-to-end design problem. To provide Controller Area Network with Flexible Data-Rate (CAN FD) communications, TI also introduced the TCAN1044EV-Q1, which is rated for Grade 0 150°C temperature operation as well (Fig. 2).

This high-speed transceiver meets the physical-layer requirements of the ISO11898-2:2016 high-speed CAN specification and supports both classical CAN and CAN FD networks up to 8 Mb/s. It’s available in an 8-lead, 4.90- × 3.91-mm SOIC for US$0.43 in 1,000-unit quantities and has a detailed datasheet, too.

More information on AEC-Q100 automotive temperature grades and why Grade 0 is critical for in-vehicle network signal isolation can be found in the TI blog, “Solving high-temperature isolation design challenges with Grade 0 digital isolators”; TI’s capacitive-isolation technology is also discussed in its “Capacitive Isolation Technology” posting.

About the Author

Bill Schweber

Contributing Editor

Bill Schweber is an electronics engineer who has written three textbooks on electronic communications systems, as well as hundreds of technical articles, opinion columns, and product features. In past roles, he worked as a technical website manager for multiple topic-specific sites for EE Times, as well as both the Executive Editor and Analog Editor at EDN.

At Analog Devices Inc., Bill was in marketing communications (public relations). As a result, he has been on both sides of the technical PR function, presenting company products, stories, and messages to the media and also as the recipient of these.

Prior to the MarCom role at Analog, Bill was associate editor of their respected technical journal and worked in their product marketing and applications engineering groups. Before those roles, he was at Instron Corp., doing hands-on analog- and power-circuit design and systems integration for materials-testing machine controls.

Bill has an MSEE (Univ. of Mass) and BSEE (Columbia Univ.), is a Registered Professional Engineer, and holds an Advanced Class amateur radio license. He has also planned, written, and presented online courses on a variety of engineering topics, including MOSFET basics, ADC selection, and driving LEDs.