Fast-switching gate-driver ICs make for ideal motor inverter switches in electric vehicles (EVs) or hybrid electric vehicles (HEVs). They take direct current from the car’s battery and convert it into high-voltage, high-current energy to power the motor. In this way, the performance of gate-driver ICs is directly connected to the performance of an EV.

Power Integrations, a provider of gate-driver technology for medium- and high-voltage inverter applications, recently introduced the SIC1182KQ (1200 V) and SIC1181KQ (750 V) drivers, both AEC-Q100-qualified. The two SCALE-iDriver devices are optimized for driving SiC MOSFETs in automotive applications, offering rail-to-rail output, fast gate switching speed, unipolar supply voltage supporting positive and negative output voltages, integrated power and voltage management, and reinforced isolation between the controller and the semiconductor device.

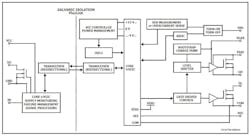

Reinforced galvanic isolation is provided by the company’s FluxLink technology, enabling safe, cost-effective designs for inverters up to 300 kW. FluxLink is a high-speed bidirectional communications link that sits across the isolation gap. Its signaling protocol provides high EMI and magnetic-field immunity, and exceeds the IEC61800-4-8 and IEC61800-4-9 standards in all three axes. It features a low propagation delay and low jitter of only ±5 ns.

FluxLink not only isolates the low-voltage input control side of the device, but also communicates back any fault conditions measured on the high-voltage side of the device back across the barrier to a microcontroller responsible for controlling and monitoring the device’s operation. The proprietary feedback technique permits precise control without the need for a bulky optocoupler and capacitive- or silicon-based inductively coupled solutions. It also avoids the performance compromises inherent in primary-side regulation (PSR), such as limited accuracy and efficiency and poor transient response versus no-load consumption.

Critical protection features include drain-to-source voltage (VDS) monitoring; SENSE readout; primary and secondary undervoltage lockout (UVLO); current-limited gate drive; and advanced active clamping (AAC), which facilitates safe operation and soft turn-off under fault conditions. AAC in combination with VDS monitoring ensures safe turn-off in less than 2 µs during short-circuit conditions to quickly protect the system in the event of a fault. The device uses the semiconductor device drain-to-source voltage to detect a short-circuit utilizing a sensing resistor network.

Gate-drive control and AAC features allow gate resistance to be minimized, thus reducing switching losses and maximizing inverter efficiency.

Michael Hornkamp, senior director of marketing for automotive gate-driver products at Power Integrations noted: “Silicon-carbide MOSFET technology opens the door for smaller, lighter automotive inverter systems. Switching speeds and operating frequencies are increasing; our low gate resistor values maintain switching efficiency, while our fast short-circuit response quickly protects the system in the event of a fault.” He added, “Even if a power device causes catastrophic driver failure, SCALE-iDriver’s isolation remains intact, ensuring that no part of the chassis will carry life-threatening high voltages.”

The new single-channel gate drivers provide up to 8 A and suit SiC MOSFETs with standard gate-emitter voltages from +15 V, with various negative voltages in the range from −3 to −15 V. The devices, which exhibit high external magnetic-field immunity, come in a compact eSOP package and are available now.