AV Transformation Design and Verification Turbocharges OEMs

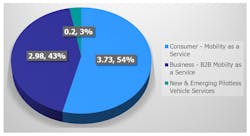

Autonomous vehicles are ushering in a new era of self-driving cars, taxis, trucks, and a host of other means of transport, which is having an enormous impact upon the fortunes of vehicle manufacturers. To stay ahead of the competition, these OEMs require a large investment in new technologies—but the returns can also be huge. Fortune.com predicts that the growth of the autonomous-vehicle (AV) market will account for seven trillion dollars of new economic activity by 2050, so the race to be first to market with fully autonomous vehicles is a big incentive (Fig. 1).

Automotive OEMs that want to start this race at the pole position must find ways to balance R&D spending between refreshing vehicle product lines today and developing the autonomous vehicles of tomorrow. They must collaborate with their supply chain (tier 1s and IC design houses) to foster similar design optimizations. Only in these ways can they bring a complete autonomous-vehicle product to market ahead of the competition.

The big winners will be those OEMs that most effectively integrate the advanced technologies required for autonomous driving into a package that’s reliable, safe, and attractive to consumers — then get those technologies to market quickly with a high level of quality. Accomplishing this requires best-in-class technology solutions that deliver at all stages of production: from IC design and requirements compliance, through systems design and integration, to entire vehicle modeling and simulation.

The answer to this immensely complex engineering challenge is a comprehensive pre-silicon validation environment that supports multi-supplier collaboration and establishes a design-to-simulation-to-emulation solution. Empowered by the performance, capacity, and flexibility of emulation, this solution fits into existing tool flows and provides a true “chip-to-city” approach that accommodates and advances the increasing digitalization of the automotive industry.

Integrated Mobility Solutions

First, let’s take a quick look at the bigger trends propelling this phenomenal shift in the automotive market. The fundamental shift is that the compute power required for AVs will increase significantly compared to existing vehicle electronics, with multicore processing and correspondingly complex software algorithms. This will require closer collaboration across the vehicle supply chain.

Major automotive manufacturers are seeking to stay ahead of the coming industry disruption, but most companies announcing autonomous-vehicle programs are startups or companies from other industries seeking to enter a traditionally impenetrable market. These agile entrants to the automotive sector will pose a threat to OEMs, and they will target the most economically viable segments of the burgeoning AV market.

Yet these companies lack the industry-specific experience and engineering resources to conquer the complexities of AV design. However, even the major automotive OEMs will face challenges that their legacy design flows are ill-equipped to handle. These include:

- The major part of AV verification and validation can no longer be achieved through real-world validation, as the number of test scenarios to properly validate AV systems explodes to millions for SAE level 5. Most estimates predict that autonomous vehicles will require the equivalent of billions of miles of testing to ensure their safety.

- The trend toward AVs creates a shift away from hundreds of ECUs per vehicle, each with relatively simple processors, toward centralized, massive-compute solutions and multicore processing.

- Complex platform electronics, including multiple CPUs, imaging, and AI processors, will require extensive verification of functionality, ISO 26262 safety requirements, and security protocols.

- Multiple system-on-chip (SoC) interfaces and bus protocols need extensive verification and validation to reduce the risk of errors and recalls in the field.

To stay viable, automotive OEMs must develop and leverage partnerships to reshape their value proposition from traditional car ownership to integrated mobility solutions. Vehicles would become highly complex mobile platforms that communicate externally to other vehicles, IoT objects, and the cloud, returning data to the driver or the vehicle electronics to inform decisions on driving.

In other words, the car is a mobile system integrated with other systems, devices, cars, and networks. Thus, OEMs have to integrate and partner with 5G companies, safety and security companies, IoT vendors, etc., elevating them from traditional car makers to vendors of mobile platforms with integrated electronics and software solutions.

Automotive OEMs can capitalize on an integrated mobility focus to leapfrog their competitors through parallel development of software and hardware, using virtualized design and verification technologies that help them understand and make tradeoffs between power, performance, and area in their ICs and SoCs. Virtualization of the software and hardware enables OEMs to create a digital twin of the full vehicle, the only viable solution for verification of autonomous vehicles.

Another advantage can be gained by using integrated data systems for requirements compliance, verification, and validation, from the component to the vehicle level. Seamless synchronization of data between the electrical, mechanical, and software components of a vehicle improves the integration of them into a single system. In addition, by adopting a secure methodology for sharing IP, OEMs will speed up their development, verification, and validation of vehicle electronics and systems.

Pre-Silicon Autonomous Validation Environment

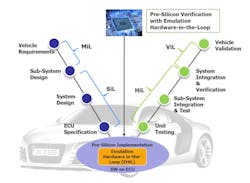

Unfortunately, the traditional verification flows for AV systems suffer a pre-silicon verification gap that prevents them from meeting these challenges. Virtual prototyping provides fast, high-level models, but it delivers insufficient accuracy for pre-silicon verification. Hardware-in-the-loop, which uses the actual silicon chip, is effective when hardware is stable. However, it stumbles with non-deterministic behavior, and because hardware is difficult to debug, hardware-in-the-loop tools are only useful for post-silicon verification.

Logic simulation, i.e., software-in-the-loop, is hardware-accurate and offers excellent debugging capabilities, but it’s too slow and lacks the capacity for full-SoC and system-of-systems verification. Finally, hardware prototyping is both fast and hardware-accurate, but it lacks capacity and has poor debug capabilities. Furthermore, its slow compile times and long time-to-visibility makes full-SoC and system-of-systems verification difficult.

Unless OEMs can fill the pre-silicon verification gap with upgraded verification capabilities, they will be stranded in the pit stop. Only hardware emulation has the capacity, performance, throughput, debug capabilities, and applications to deliver a fully virtualized solution for both a digital twin of a vehicle, and for closing the pre-silicon verification gap (Fig. 2).

Hardware emulators typically run from 1,000 to 10,000 times faster, compared to a software simulator running on a general-purpose computer. An emulator includes a hardware system, operating system software, and software applications. Emulation technology enables new design and verification methodologies, including virtualization, on everything from chips to systems-of-systems, and can be shared across global teams.

Emulation has been field-proven and is a trusted platform that can enable OEMs to transition from software-in-the-loop to hardware-in-the-loop. For example, the Veloce emulation platform from Mentor, a Siemens Business, can connect to software-in-the-loop tools and electromechanical tools. It’s the centerpiece of Siemens’ PAVE360 program for integrated autonomous-vehicle design and verification flow, which enables capabilities for full, closed-loop validation of the sensing, decision-making, and actuating paradigm at the heart of all automated driving systems (Fig. 3).

Closed-loop validation hinges on rigorous pre-silicon validation of deterministic (rules-based) and non-deterministic (AI-based) approaches to safe self-driving in the context of the full digital twin. This pre-silicon autonomous validation environment extends digital-twin simulation beyond processors to include automotive hardware and software subsystems, full vehicle models, fusion of sensor data, traffic flows, and even simulation of the smart cities through which self-driving cars will ultimately travel.

Such comprehensive pre-silicon validation environments for multi-supplier collaboration across the automotive ecosystem enable and accelerate the development of innovative autonomous-vehicle platforms. It fits into the traditional automotive tool flow, connects to well-known tools, and supports the tools that speak to well-known automotive standards and interfaces; e.g., SystemC/IEEE TLM, and the Electromechanical/Functional Mockup Interface (FMI).

Emulation provides a portfolio addressing design exploration, validation, and verification of autonomous vehicles to optimize R&D spending on AV development. A pre-silicon autonomous validation environment provides continuity from the IC requirements and design stage through systems design and integration, enabling OEMs and their suppliers to develop safe, reliable, and secure autonomous platforms on time and on budget. It also supports collaboration between OEMs and suppliers, through parallel development in a simulated environment.

Conclusion

OEMs will be able to create a sustainable, competitive advantage in the market by embracing this transformational change in the way they design and verify the complex electronics and software needed for autonomous vehicles. An emulation-based, hardware-in-the-loop solution delivers on the verification needs for autonomous driving.

Emulation delivers on the industry need for pre-silicon verification of AV chips. It provides solutions across global teams for functional safety needs, using realistic driver scenarios, vehicle dynamics, and metrics for power analysis in a virtual environment with the speed and capacity needed for successful hardware/software integration. By providing accurate, integrated toolsets for the functional verification of automotive SoCs and ECUs, including safety and low-power analysis capabilities, emulation allows tier 2/semi suppliers to deliver platforms to OEMs that meet their specifications and reduce the risk of costly recalls.

Richard Pugh is a Product Marketing Manager in the Emulation Division at Mentor, a Siemens Business.

About the Author

Richard Pugh

Product Marketing Manager, Emulation Division, Mentor, a Siemens Business

Richard Pugh is a Product Marketing Manager in the Emulation Division at Mentor, a Siemens business. He has more than 30 years of EDA experience, with a focus today on verification solutions for ADAS applications and autonomous vehicles.