Samsung Electro-Mechanics Deepens Automotive MLCC Lineup

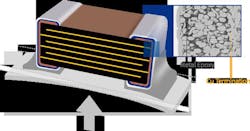

Multilayer ceramic capacitors (MLCCs) are a passive component that supply needed amounts of power for chips, prevent electromagnetic wave interference, and control current so that it flows uniformly and stably in the circuits of electronic products.

Used in automotive power, safety, comfort and entertainment systems, the traditional gasoline-powered car contains at least 3,000 MLCCs, while high-end electric vehicles may use 10,000 MLCCs. What’s more, as an increasing number of car models become equipped with sophisticated arrangements, such as advanced driver-assistance systems (ADAS), demand for MLCCs is being pushed to even higher levels.

Consider that despite the global COVID pandemic, the global MLCC market is forecast to grow from US$13.3 billion this year to US$16.8 billion by 2024 and the automotive MLCC sector is projected to expand its share from 29% to 35% during the period, according to the firm KB Investment & Securities.

Given all of that, it comes as no surprise that Samsung Electro-Mechanics, an electronic parts supplier affiliated with Samsung Electronics, has developed five new types of MLCCs for automobiles—three for powertrain applications and two for anti-lock brake systems—all of which will be supplied to global automakers. The company will be immediately supplying the newly developed MLCCs to a global automotive parts maker that wasn’t identified during the formal product introduction.

An MLCC for powertrains must handle high capacity in a high-temperature and high-pressure environment. Typically, small MLCC case sizes are 0402 and smaller, while larger sizes will be 0603 and greater. A case size of 0402 measures 1.016 × 0.51 mm (0.04 inches by 0.02 inches). Samsung Electro-Mechanics has succeeded in developing a MLCCs in the 2012 size (2.0 × 1.2 mm) with 1.0 µF, the 3216 size (3.2 × 1.6 mm) at 2.2 µF, and the 3225 size (3.2 × 2.5mm) at 4.7 µF.

The company highlighted its use of proprietary ceramic and electrode materials and a precision lamination method as enabling the high electric capacity for each size. Also noted was that its new components can be stably used even at high voltages of up to 100 V. Samsung also pointed out that the existing 12-V automotive electrical system has recently been transforming to a higher voltage of 48 V, so its MLCCs can be widely applied to markets that require high-voltage products such as automotive batteries.

Samsung Electro-Mechanics also introduced two types of MLCCs for anti-lock braking systems (ABS). As automotive ABS is a component directly related to safety, components designed for this subassembly must ensure a high level of reliability. These new ABS-targeted MLCCs are the 2012 (2.0 × 1.2 mm) at 4.7 µF and the same-sized unit at 2.2 µF.

The company said the new MLCCs represent a 20% increased lifespan compared to existing products and a 5% improvement in safety margin. The ability to withstand high voltage also was improved for stable operation under extreme environments such as high temperatures (above 150℃), low temperatures (−55℃), and high humidity (85% or higher humidity), with a greater tensile strength against external impact.

In announcing its new MLCCs, Samsung Electro-Mechanics said its new products pass the rigorous manufacturing criteria of AEC-Q200 (certification for passive automotive components), the time-proven automotive reliability test standard, and they will also satisfy the thorough verification requirements of each client.

The company has stepped up production of automotive MLCCs since 2016 by establishing a dedicated production line in Busan, Korea in 2018, followed by the construction of a new automotive MLCC factory in Tianjin, China. Samsung said it will be able to turn out MLCCs from its Tianjin plant by the end of this year.