3 Trends Propel Vehicle Electrification

Download this article in PDF format.

The automotive industry is pursuing vehicle electrification on several fronts, with key initiatives driving trends in three areas. First, the addition of 48-V batteries helps manage power-hungry loads at lower currents while reducing weight and boosting efficiency. Second, the evolution toward the wireless battery-management system (BMS) offers improved reliability while also boosting efficiency. Third, a powertrain combo-box architecture improves power density, increases reliability, and optimizes cost.

Sponsored Resources:

- Bridging 12 V and 48 V in dual-battery automotive systems

- Three questions to ask about wireless BMS for hybrid and electric vehicles

- Integrate your powertrain systems to create an EV combo-box architecture

Bridging 12-V and 48-V Systems

The 12-V lead-acid battery has had a long run in the automotive industry. But in the face of increasingly strict emission regulations and growing power requirements driven by advanced electronics and the conversion from mechanical to electronic components, the 12-V system can no longer go it alone. In response, the industry has developed a 48-V lithium-ion battery-based system that can deliver higher power at lower currents.

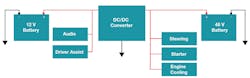

Note that the 48-V system doesn’t replace the 12-V system, but rather works alongside it. While the 12-V system powers loads involving infotainment, lighting, and window controllers, the 48-V system can support heavier loads such as starter-generator units, air-conditioning compressors, active chassis systems, turbochargers, and regenerative braking.

Also note that the two systems don’t work in isolation. To that end, you can use a bidirectional buck-boost controller to support a dual-bus topology that bridges the 12- and 48-V rails in dual-battery systems.

The basic components for such a bridging system are shown in Figure 1. Bidirectional power transfer supports the charging of either battery and allows each battery to provide power to the opposite battery’s power rail in the event of an overload condition. A buck converter can transfer power from the 48-V rail to the 12-V rail, while a boost converter can transfer power from the 12-V rail to the 48-V rail.

Two converters, however, take up valuable board real estate and increase system complexity and cost. In contrast, Texas Instruments’ (TI) LM5170-Q1 buck/boost controller implements all of the control circuitry necessary for bidirectional energy conversion, making systems simpler compared with discrete implementations. Employing multiple controllers in parallel allows the 48-V rail to deliver up to about 10 kW.

To enable you to explore your design options with the LM5170-Q1, TI offers the LM5170 bidirectional converter evaluation module (EVM). You can control the power-flow direction using either an external signal or an onboard jumper. Through onboard interface headers, you can operate the EVM with a digital signal processor (DSP), FPGA, MCU, or other digital controller. Paralleling two or more EVMs creates a multiphase interleaved converter for higher power.

TI also has a bidirectional dc-dc converter reference design for 12-V/48-V automotive systems. The reference design specifies two LM5170-Q1 devices and a C2000 TMS320F28027F MCU for power-stage control.

Wireless BMS for Hybrid and Electric Vehicles

The second trend toward vehicle electrification involves the evolution toward a wireless BMS, which promises improved reliability and reduced vehicle weight to boost efficiency. The traditional wired-BMS architecture connects battery packs in a daisy-chain configuration, posing manufacturing and maintenance challenges. In contrast, a wireless BMS employs wireless chipsets to communicate voltage and temperature data from each cell to the BMS microcontroller. The reduction in cables lowers weight and saves cost.

- First, is it reliable? You can quantify the reliability of the wireless link and network by measuring packet error rates and the probability of successfully sending a message between a transmitter and receiver—the latter should be better than 99.999%.

- Second, is the wireless BMS safe? Ideally, the system should meet the requirements of Automotive Safety Integrity Level D, as defined by the International Organization for Standardization 26262 road-vehicle standard.

- Third, is it secure? Systems should provide encrypted messages using security enablers such as cryptographic accelerators with key exchange and refreshment mechanisms to prevent security breaches.

You will also want to take into account issues related to design flexibility, serviceability, and measurement capability. A wired BMS, with its larger overall footprint and cumbersome wires, limits flexibility and is more difficult to service, while the wireless BMS offers a smaller footprint, more design flexibility, and more options for placement within the vehicle. In addition, time-synchronized voltage and current measurements could be challenging for a wired BMS, while a wireless BMS naturally enables time-synchronized measurements.

Careful consideration of all these issues can help you determine whether a wired or wireless BMS is most appropriate for your design.

EV Combo-Box Architectures

The third trend involves the move toward an electric-vehicle powertrain combo-box architecture, which can improve power density, increase reliability, and optimize cost while simplifying design and assembly. It also provides the means to standardize and modularize.

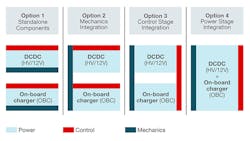

A combo-box architecture integrates equipment such as an inverter, power-distribution unit, high-voltage dc-dc converter, and onboard charger. You can implement a combo-box architecture in many ways. A combo box incorporating an onboard charger and high-voltage dc-dc converter illustrates four common options (Fig. 2).

Option 1 makes use of standalone components. With option 2, the dc-dc converter and onboard charger share a mechanical housing; the cooling system can be shared or split. Option 3 employs control-stage integration and is now evolving toward option 4, which adds power-stage integration. Option 4 offers the best cost advantages, because it minimizes the required number of power switches and magnetic components. Nevertheless, it requires the most complex control algorithm. In addition, a highly integrated combo box requires careful magnetic integration for optimal performance, and you will need an efficient cooling system to dissipate the heat generated within the smaller box.

Conclusion

Dual 48-V and 12-V battery topologies, wireless battery-management systems, and combo-box architectures are key milestones on the road to vehicle electrification. These technologies can keep costs low and offer engineers flexible design opportunities to make vehicles more efficient, reliable, and serviceable.

Sponsored Resources:

About the Author

Rick Nelson

Contributing Editor

Rick is currently Contributing Technical Editor. He was Executive Editor for EE in 2011-2018. Previously he served on several publications, including EDN and Vision Systems Design, and has received awards for signed editorials from the American Society of Business Publication Editors. He began as a design engineer at General Electric and Litton Industries and earned a BSEE degree from Penn State.