Collaboration Delivers Integrated Solutions for ADAS and Self-Driving Vehicles

Artificial intelligence (AI) and machine learning (ML) are ubiquitous for advanced driver-assistance systems (ADAS) and self-driving vehicles. This involves a growing number of sensors generating lots of data that needs to be processed in real time. ML models are being deployed based on billions of bytes of data recorded in the field in addition to simulations, but more is needed to further refine and improve the models in current and future vehicles.

Utilizing vehicles in the field as well as test vehicles are ways of obtaining this information, which can then be used in AI training in the cloud. However, the two terabytes of data per hour that today’s vehicles can generate would swamp any currently existing wireless communication link, so reducing the amount of information that’s sent to the cloud is critical.

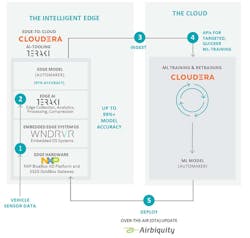

Over-the-air (OTA) updates complete the loop by providing updated models to those vehicles. This isn’t a real time cycle with changes being made automatically based on current inputs, but it does allow for the generation of new models that can then be certified and downloaded to the vehicles.

Such a process involves lots of hardware and software components. Consequently, The Fusion Project (Fig. 1) has been started to make this loop easier to implement and maintain. The project initially targets intelligent vehicle lane-change detection, but it will address all aspects of ADAS and self-driving vehicles as time goes on.

The initial group of companies cover all the bases in the loop:

- Airbiquity: OTA software management

- Cloudera: Data lifecycle solutions and cloud services

- NXP: Vehicle processing platforms

- Teraki: Edge data AI

- Wind River: Intelligent systems platform software

The integration of the hardware and software in the loop is a work in progress. Developers will also need to work with the companies individually—it’s possible to use different solutions within the design.

The current framework is based on data-acquisition support on NXP hardware running Wind River’s operating system, along with Teraki’s analytics and compression support that helps reduce the amount of information shipped to the cloud (Fig. 2). Cloudera’s cloud provides support for obtaining data from the vehicles as well as running the software for further analytics and ML training. Airbiquity’s secure OTA updates complete the loop by delivering updated models that are more efficient and accurate.

Though the loop is easy to understand, getting all of the pieces to work together isn’t easy. The companies have integrated the systems that provide an overall solution, but it must incorporate additional hardware and software. Likewise, developers will have to work with each of the companies individually, but with the knowledge that the pieces work together and have been tested in an overall solution.

“Automakers are constantly challenged with implementing complex technologies such as those required for the next phase of advanced ADAS and autonomous-vehicle features,” says Phil Magney, Founder and President of VSI Labs, and former Co-Founder of the Telematics Research Group. “There are many facets to a next-generation data-management technology stack that continuously improves and deploys AI machine-learning models, so automakers need a vehicle-to-cloud solution like the one created by The Fusion Project that leverages key technologies from across the automotive ecosystem.”

Automotive complexity continues to intensify and integrating systems has thus become a major part of providing solutions in the automotive space. Having much of this integration in place can significantly reduce time to market as well as lower overall costs.

About the Author

William G. Wong

Senior Content Director - Electronic Design and Microwaves & RF

I am Editor of Electronic Design focusing on embedded, software, and systems. As Senior Content Director, I also manage Microwaves & RF and I work with a great team of editors to provide engineers, programmers, developers and technical managers with interesting and useful articles and videos on a regular basis. Check out our free newsletters to see the latest content.

You can send press releases for new products for possible coverage on the website. I am also interested in receiving contributed articles for publishing on our website. Use our template and send to me along with a signed release form.

Check out my blog, AltEmbedded on Electronic Design, as well as his latest articles on this site that are listed below.

You can visit my social media via these links:

- AltEmbedded on Electronic Design

- Bill Wong on Facebook

- @AltEmbedded on Twitter

- Bill Wong on LinkedIn

I earned a Bachelor of Electrical Engineering at the Georgia Institute of Technology and a Masters in Computer Science from Rutgers University. I still do a bit of programming using everything from C and C++ to Rust and Ada/SPARK. I do a bit of PHP programming for Drupal websites. I have posted a few Drupal modules.

I still get a hand on software and electronic hardware. Some of this can be found on our Kit Close-Up video series. You can also see me on many of our TechXchange Talk videos. I am interested in a range of projects from robotics to artificial intelligence.