Fast-Switching 650-V Automotive Hybrid IGBT Has Built-In SiC SBD

What you'll learn:

- Key specifications that separate this new IGBT apart from others.

- What is a freewheeling diode?

- The multiple benefits of using SiC over silicon.

As automakers and tier 1s strive to develop more efficient systems, they’re broadening the types of power semiconductors used in various vehicle converter and inverter circuits. In turn, semiconductor suppliers are contributing by developing both low-loss silicon carbide (SiC) and conventional silicon power devices.

Last week, for example, Rohm announced its new RGWxx65C series of hybrid IGBTs with an integrated 650-V SiC Schottky barrier diode (SBD). Insulated gate bipolar transistors (IGBTs) contribute to higher efficiency and energy savings for a wide range of high-voltage and high-current applications. An IGBT's value comes from the combination of its fast yet smooth switching ability and its high efficiency, which saves energy while maintaining performance.

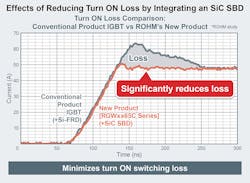

The RGWxx65C series utilizes Rohm’s low-loss SiC Schottky barrier diodes in the IGBT’s feedback block as a freewheeling diode that has almost no recovery energy and thus minimal diode switching loss (Fig. 1). A freewheeling diode is used to protect the circuit from damage due to abrupt reduction in the current flowing through the circuit. It’s also known as a flyback diode.

In addition, since the recovery current needn’t be handled by the IGBT in turn-on mode, it reduces IGBT turn-on loss. According to Rohm, both effects together result in up to 67% lower loss over conventional IGBTs and 24% lower loss compared with superjunction MOSFETs, when used in vehicle chargers. This results in lower power consumption.

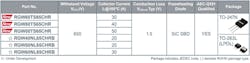

You will note from Figure 2 that the series of three new parts varies with regard to collector current (Ic), ranging from 30 to 50 A. An IGBT circuit has three terminals called collector (C), gate (G) and emitter (E). The collector current represents the dc current level that will take the junction to its rated temperature. In a typical operation, voltage is applied between the collector and the emitter. This causes a current to flow from the collector to the emitter. When a current overload occurs, collector current rises rapidly until it exceeds that which the device can sustain with the applied gate voltage.

The hybrid IGBTs feature an integrated 650-V SiC Schottky barrier diode. The total capacitive charge (QC) of SBDs is small, reducing switching loss while enabling high-speed switching operation. In addition, unlike Si-based fast-recovery diodes (FRDs), where the reverse recovery time (tRR) increases along with temperature, SiC devices maintain constant characteristics, resulting in better performance.

The SiC Advantage

Compared to silicon, SiC parts offer superior material advantages such as wider bandgap, higher thermal conductivity, and higher critical breakdown field strength. These devices are capable of operating at high voltages, high frequencies, and at higher junction temperatures, resulting in reduced heatsinking. This is important because when Si-based devices become smaller in terms of area, it becomes more difficult to extract the heat generated by electrical conversion processes. SiC dissipates the heat better.

SiC Schottky diodes also can replace Si diodes in inverters. By replacing Si diodes with their SiC Schottky diode counterparts, the losses of an inverter should decrease considerably. Consequently, compared with silicon power devices, SiC power devices are expected to have a great impact on inverter efficiency, weight, volume and reliability.

Since SiC Schottky diodes have negligible reverse recovery, they don’t stress the main switches as much as Si diodes. Therefore, it’s possible to operate a Si-SiC hybrid inverter at higher switching frequencies.

The Rohm hybrid IGBT devices, qualified under the AEC-Q101 automotive reliability standard, are well-suited for automotive and industrial applications that handle high power, such as onboard chargers and dc-dc converters used in electric vehicles.

By way of review, in an electrically powered vehicle, VAC power is taken from a socket, converted into dc power in the car, and then used to charge the batteries. The charger power blocks consist of an ac-dc front end followed by a dc-dc converter to provide the charge voltage to the battery. The key factors for this kind of application are high efficiency, high power density, and provision for bidirectional energy flow. SiC technology matches all of those requirements.

In addition to these hybrid IGBTs, Rohm offers products utilizing silicon FRDs as the freewheeling diode, as well as products without a freewheeling diode. The company is focusing not only on product and technology development for SiC power devices, but on silicon products and driver ICs as well. A range of design support material is available on Rohm’s website, including simulation (SPICE) models and application notes on drive circuit design. Samples of the hybrid IGBTs are available now, with mass production scheduled for December 2021.