Using 3D Printing Techniques to Generate Electricity from Waste Heat

This article appeared in Machine Design and has been published here with permission.

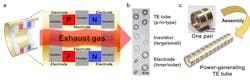

In breakthrough research, engineers affiliated with UNIST (located in Korea’s largest industrial city, Ulsan) have developed a thermoelectric technology to produce power-generating tubes using 3D printing techniques.

Thermoelectric (TE) technologies show promise in enhancing fossil energy efficiencies by generating electricity from waste heat from industrial or automobile exhaust gases. However, typical thermoelectric solutions manufactured in traditional processes do not fulfill efficiency and low-cost requirements. This is especially true for exhaust pipes, noted the researchers.

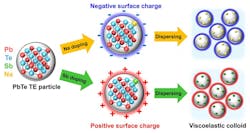

To address this inefficiency, a thermoelectric tube using a 3D printed ink made of lead (Pb) and tellurium (Te) was created. The researchers explained that metal particles were mixed inside a glycerol solvent to provide viscoelasticity, a status that exhibits both viscous and elastic characteristics.

The tube has a high thermoelectric performance at temperatures between 400 and 800°C. This is also the temperature range of a car’s exhaust gases.

The research was jointly led by Professor Han Gi Chae and Professor Jae Sung Son from the Department of Materials Science and Engineering, along with Professor Sung Youb Kim from the Department of Mechanical Engineering, at UNIST.

Their experimental and computational findings demonstrated that the performance of the power-generating TE tube fabricated from 3D-printed PbTe tubes were an effective strategy to design system-adaptive, high-performance thermoelectric generators.

“Through this research, we will be able to effectively convert heat generated by factory chimneys, the most common type of waste heat source, into electricity,” said Son. He added that the tube shape makes it more effective in collecting heat than a conventional rectangular parallelepiped shape.

Chae reported that the use of 3D printing technology in the production of thermoelectric materials can overcome limits of conventional materials. “The new technology for providing viscoelastic characteristics to 3D printed materials will be used in various other sectors,” he said.

Their work has been featured on the front cover of Advanced Energy Materials.

Reference

Jungsoo Lee, Seungjun Choo, Hyejin Ju, et al., “Doping-Induced Viscoelasticity in PbTe Thermoelectric Inks for 3D Printing of Power-Generating Tubes,” Adv. Energy Mater., (2021).

About the Author

Rehana Begg

Editor-in-Chief, Machine Design

As Machine Design’s content lead, Rehana Begg is tasked with elevating the voice of the design and multi-disciplinary engineer in the face of digital transformation and engineering innovation. Begg has more than 24 years of editorial experience and has spent the past decade in the trenches of industrial manufacturing, focusing on new technologies, manufacturing innovation and business.

Her B2B career has taken her from corporate boardrooms to plant floors and underground mining stopes, covering everything from automation & IIoT, robotics, mechanical design and additive manufacturing to plant operations, maintenance, reliability and continuous improvement.

Begg holds an MBA, a Master of Journalism degree, and a BA (Hons.) in Political Science. She is committed to lifelong learning and feeds her passion for innovation in publishing, transparent science and clear communication by attending relevant conferences and seminars/workshops.