Schottky Barrier Diodes Geared to Automotive Apps

A diode is one of the basic components commonly used in electronic circuit designs. Diodes are frequently employed in a variety of circuits that handle rectification and protection. In automotive applications, Schottky diodes can rectify a current by facilitating a quick transition from conducting to blocking state. They feature low reverse-leakage current at high temperatures that minimizes circuit losses and increases protection against thermal runaway.

Because these devices have both a high current density and low forward-voltage drop, Schottky diodes serve engineers well in power rectifier applications. In Schottky diodes, sometimes called Schottky barrier diodes (SBDs), metal is substituted for the p-type semiconductor, creating what’s known as a Schottky barrier.

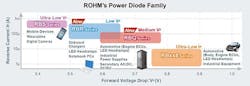

As lower power consumption is required in most applications, the adoption of SBDs in particular is on the rise. To keep pace with growing demand, ROHM Semiconductor strengthened its lineup of SBDs that balance small size with low VF and IR—characteristics demanded by the automotive sector. In a SBD, if VF is lowered to improve efficiency, IR (which is inversely related to VF) will become higher. This increases the risk of thermal runaway, so it’s important to balance both VF and IR when selecting SBDs for circuit design.

ROHM’s expanded portfolio of SBDs includes 24 new models (12 RBR series and 12 RBQ series). These devices—178 altogether—are aimed at protection and rectification circuits. The lineup of automotive-grade SBDs contributes to lower power consumption, smaller size, and higher reliability. New processes enable both series to improve chip performance by 25%, according to the company, resulting in low VF and IR characteristics for the RBR and RBQ series, respectively.

To meet the need for higher voltages, 12 new 100-V products have been added (six for automotive and six for consumer electronics); both the RBR and RBQ series are qualified under the AEC-Q101 standard to ensure automotive-grade reliability. In addition, 12 of the products adopt a compact package (PMDE package 2.5 × 1.3 mm) that reduces mounting area by 42% compared to existing products (PMDU package), again, according to ROHM.

The RBQ series further delivers low IR characteristics that enable stable operation in high temperature environments, significantly reducing the risk of thermal runaway, which is a concern with SBDs. As such, they’re well-suited for automotive powertrain applications as well as for power supplies for industrial equipment that operate in high-temperature environments.

Application examples for the RBR series include LED headlamps and car accessories, while the RBQ series target xEVs, engine ECUs, and secondary rectification in ac-dc and dc-dc circuits. In the RBR series, a standard 3.5- × 1.6-mm package can be replaced with a 2.5- × 1.3-mm size. Reverse power loss in the RBQ series, at 0.4 W, is said to be 60% less than the typical part (4.5-V/20-A type).

ROHM also offers a range of 650- and 1200-V silicon-carbide (SiC) SBDs (some are AEC-Q101 qualified). The company notes that the small capacitance charge of SiC SBDs enables high switching speeds. Its RGWxx65C series of hybrid IGBTs have an integrated 650-V SiC SBD. Using SiC in place of silicon bestows the diode with a higher breakdown voltage and greater current-carrying capacity. As SiC SBDs make power-conversion systems more reliable, they’re routinely found in battery chargers and charging circuits for electric and hybrid vehicles.