Temperature Ruggedness of Passive Components Needs Its Own Perspective

Ensuring system ruggedness and long-term reliability requires addressing multiple challenges. The factors that adversely affect long-term performance include temperature extremes, vibration, mechanical stresses, electrostatic discharge (ESD), and even harsh and corrosive atmospheres.

Certainly, nearly every circuit engineer is familiar with the issue of temperature, and it’s the first issue that needs to be addressed. In most cases, where there’s power, there’s dissipation, and where there’s dissipation, there’s likelihood of heat buildup and temperature increase. Engineers must deal with the consequences of this unavoidable condition, as it often listed as a significant design constraint.

The designer’s hierarchy of concerns usually starts with changes in performance of active devices. Even if the MOSFET or IGBT has a temperature rating that’s high enough, the device parameters can shift dramatically due to well-known changes in factors such as leakage currents. Therefore, the first concern is making sure that the component not only stays within its safe operating area (SOA), but also delivers the needed performance. In some cases, additional temperature-compensation circuits or use of components with compensating temperature characteristics are needed to keep circuit performance within bounds.

After active devices, it’s time to examine the passive components. These tend to have less-dramatic temperature-related drift than semiconductors. Basic RLC components—resistors, inductors, and capacitors—have well-known shifts in specifications due to temperature coefficient of resistance (or inductance or capacitance), which are easier to assess than the changes that occur in active devices. Further, the raw materials used in passives have fairly high temperature thresholds, making their physical implementation a less-daunting challenge than it is for semiconductors. (“Wet” capacitors are another story, of course, since their basic chemistry is adversely affected.)

Resistors Make Their Own Problems

In some ways, the most troublesome component in the RLC trio is the resistor, due to its self-heating. That’s a self-induced and unavoidable consequence of its resistance function. In contrast, any self-heating of capacitors and inductors is due to their “imperfections” (dc resistance of the inductor windings, or equivalent series resistance of the capacitor), rather than their primary role. This means that their main source of heat issues is ambient, not self-induced.

Using a passive device that can withstand those higher temperatures may make it seem like the temperature-related ruggedness concerns become non-issues. But that’s not the case at all. There’s still the harder-to-assess problem of thermal shock, which leads to minute fractures and crack growth. These can occur within the component or at its leads—anywhere there’s a material-to-material mating or joint.

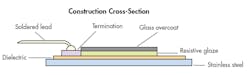

Merging high-temperature, thermal-shock, and vibration ruggedness into a “simple” passive component such as a resistor requires sophisticated design and fabrication, as shown in WDBR series from TT Electronics, which uses a steel substrate.

This impact of thermal shock is greatly aggravated by the on/off cycling of the circuit in which the component is being used, which is typical of automotive applications. The result is thermally induced stress fractures due to repeated expansion/contraction of materials, especially when they have different coefficients of expansion. That’s why the development of a hermetic glass-ceramic seal, which would not be affected by such cycling, was a major material advance in the early 1900s.

Unlike simulations of the effect of higher temperature alone on active- or passive-component performance, modeling the consequences of thermal shock is very difficult. That’s because it often requires determining properties of both the materials and combinations under a variety of test scenarios. In addition, cycling can cause permanent shifts in key parameters of materials.

Designer’s Options Span Operating Sequence to BOM Selection

What options are available to designers? In some cases, systems are deliberately left powered up, or not turned fully off, to limit thermal shock. (Obviously, this is inefficient and often no longer allowed under strict energy mandates.) For example, high-power vacuum tubes often kept “warm,” and theater spotlights (which are still incandescent in most cases) are cut back to about 10-20% of full power when not in use.

A better alternative is use a smarter power controller that slowly turns power on (and sometimes off). In fact, the automated lighting controls now used in most live theaters are programmed to turn the lamp on slowly prior to when the script calls for full lights at a cue point.

Another option is to use passives that are specially designed to live with thermal shock and vibration. For example, the WDBR series of resistors from TT Electronics (12 to 150 Ω) targets applications such as current sensing, dynamic braking, and charge/discharge current limiting in hybrid and electric vehicles. These resistors use steel rather than ceramic for their substrate onto which a thick-film conductor and resistor pattern is printed and fired, and the entire resistor is protected with a high-temperature overglaze (see figure).

Still, the fact remains that the effect of thermal shock is a function of many variables. These include the nominal temperature, the high/low temperature excursion, thermal mass, the specific materials and their temperature coefficients, the mating or bonding between the disparate materials, and amount of associated vibration, to cite a few factors.

There’s actually a quaint reminder of how little was known about the interrelated effects of ambient temperature, thermal shock, and vibration until the mid-20th century, when planes flew higher into thinner, colder air. Metal fatigue was the subject of the dramatic 1951 movie “No Highway in the Sky” starring James Stewart and Marlene Dietrich, in which Stewart portrays an aerospace engineer who discovers why those new planes have been crashing. We’ve come a long way since then, both in our requirements and the ways we meet them. Now, there’s AEC-Q200, the standardized “Stress Test Qualification for Passive Components” for automotive applications.

About the Author

Bill Schweber

Contributing Editor

Bill Schweber is an electronics engineer who has written three textbooks on electronic communications systems, as well as hundreds of technical articles, opinion columns, and product features. In past roles, he worked as a technical website manager for multiple topic-specific sites for EE Times, as well as both the Executive Editor and Analog Editor at EDN.

At Analog Devices Inc., Bill was in marketing communications (public relations). As a result, he has been on both sides of the technical PR function, presenting company products, stories, and messages to the media and also as the recipient of these.

Prior to the MarCom role at Analog, Bill was associate editor of their respected technical journal and worked in their product marketing and applications engineering groups. Before those roles, he was at Instron Corp., doing hands-on analog- and power-circuit design and systems integration for materials-testing machine controls.

Bill has an MSEE (Univ. of Mass) and BSEE (Columbia Univ.), is a Registered Professional Engineer, and holds an Advanced Class amateur radio license. He has also planned, written, and presented online courses on a variety of engineering topics, including MOSFET basics, ADC selection, and driving LEDs.