Automotive Photorelay Handles Up to 1,000-V Battery Rails

In many designs, a suitable single-function building-block component that functions as the interface between two disparate subsystems plays a critical role. One such class of component is the optocoupler (the level-shifter is another), as it provides prudent and often mandated galvanic (ohmic) isolation via an optical barrier. These isolation requirements are now rapidly increasing due to the higher battery-pack voltages in all-battery and hybrid electric vehicles (BEVs and HEVs) as well as power-storage systems.

Addressing this situation, the TLX9160T solid-state photorelay from Toshiba Electronic Devices and Storage Corporation (TAEC) targets vehicle requirements related to the battery management system (BMS), ground fault detection, and identifying faults with mechanical relays. This photorelay is the solid-state functional equivalent of the basic, normally open (NO), 1-Form-A classic single-pole single-throw (SPST) electromechanical relay (Fig. 1).

With an infrared LED optically coupled to a photo-MOSFET, it boasts a high output-withstand voltage (VOFF) of at least 1,500 V and is capable of operating from a supply voltage (VDD) of up to 1,000 V, ensuring that it’s compatible with the vast majority of traction batteries. The maximum forward current (IF) is 30 mA while on-state current (ION) is 50 mA and off-state current (IOFF) is just 100 nA.

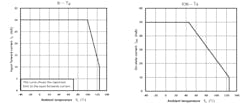

Temperature dependence—a critical factor for these devices in their target applications—is defined in the seven-page datasheet, which also provides other static and dynamic-performance characterizations (Fig. 2).

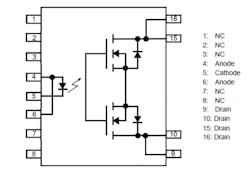

What’s the difference between a photocoupler (optocoupler) and a photorelay? A Toshiba FAQ addresses this question: “A photocoupler consists of an LED at the input side and a photodetector at the output side combined together inside, and a photocoupler product varies depending on the type of photodetector at the output side. Its main varieties include a transistor-output photocoupler, IC-output photocoupler, Triac-output photocoupler, and MOSFET-output photocoupler (called a ‘photorelay’)” (Fig. 3).

Their FAQ answer continues: “A photorelay is a device with two MOSFETs connected common-source at the output stage provided with functionality equal to that of a mechanical relay or lead relay. Since the MOSFETs have linear output characteristics in their voltage-current characteristics, this device is distinctive in that it cannot only function as a simple switch, but also switch analog signals.”

At the voltages supported by this photorelay, standards are rigorous and meeting them requires careful attention to details. The modified SO16L-T package is made from a resin material in IEC60664-1 material group I, which has a Comparative Tracking Index (CTI) exceeding 600. Also, the TLX9160T has four fewer pins (pins 11 to 14 are removed from the standard SO16L package) to meet spacing mandates.

The product features a creepage distance of at least 5 mm at its detector, ensuring that it’s compatible with supply voltages up to 1000 V (pollution degree 2) as defined by IEC60664-1. As a result, the isolation voltage (BVS) is 5,000 Vrms (minimum) and internal creepage and clearance distances are 8 mm.

The device is fully AEC-Q101 qualified with an operating temperature (Topr) of −40 to +125°C. In addition to the datasheet, a 12-page application note “Automotive high-voltage photorelay’s applications and withstanding voltage” provides useful tutorial insight.

About the Author

Bill Schweber

Contributing Editor

Bill Schweber is an electronics engineer who has written three textbooks on electronic communications systems, as well as hundreds of technical articles, opinion columns, and product features. In past roles, he worked as a technical website manager for multiple topic-specific sites for EE Times, as well as both the Executive Editor and Analog Editor at EDN.

At Analog Devices Inc., Bill was in marketing communications (public relations). As a result, he has been on both sides of the technical PR function, presenting company products, stories, and messages to the media and also as the recipient of these.

Prior to the MarCom role at Analog, Bill was associate editor of their respected technical journal and worked in their product marketing and applications engineering groups. Before those roles, he was at Instron Corp., doing hands-on analog- and power-circuit design and systems integration for materials-testing machine controls.

Bill has an MSEE (Univ. of Mass) and BSEE (Columbia Univ.), is a Registered Professional Engineer, and holds an Advanced Class amateur radio license. He has also planned, written, and presented online courses on a variety of engineering topics, including MOSFET basics, ADC selection, and driving LEDs.