This article is part of the TechXchange: EV Battery Management

Members can download this article in PDF format.

What you’ll learn:

- Design considerations for the power solution in an 800-V system.

- How an 800-V bus system impacts EV design.

- How 800 V enables reduced charging time.

- How InnoSwitch3-AQ ICs deliver solutions for 400-, 600-, and 800-V EV designs.

Many countries are enacting legislation to increase the number of electric vehicles (EVs), with the goal of phasing out or eventually banning petrol and diesel vehicles. While early adopters may have been motivated by environmental benefits, a sizable portion of the market also remains concerned with range limitations and charging times of EVs.

The automotive industry is being challenged to innovate and create solutions that appeal to a larger audience, which is driving the trend to higher battery voltages. Most of the passenger EVs on the road today run using 400-V batteries. EV buses and trucks are 600-V-class vehicles, and 800 V is starting to be adopted for passenger vehicles.

The introduction of 800-V systems, a significant step up from existing 400-V systems, is happening faster than many predicted. What are the benefits of an 800-V system, and how do they help solve some of the problems that have been barriers to consumers and slowed the rollout of electric vehicles?

How Does an 800-V Battery Impact the Vehicle Design?

The core elements of a brushless dc (BLDC) motor are the rotor that generates a dc magnetic field (typically permanent magnets or a dc armature winding) and the stator that contains copper windings through which ac current is passed.

Motion relies on the interaction of the rotor magnetic field and a rotating magnetic field generated by time-controlled currents in the stator windings. As the motor operating voltage increases for a given input power, it reduces the input RMS current and, therefore, the stator winding copper losses. Losses are typically reduced by a factor of 4 using an 800- versus a 400-V supply.

This offers the opportunity to reduce the copper winding wire diameter, which decreases the overall volume as well as increases the packing efficiency, allowing for smaller motors. The same lower current requirements in an 800-V system reduce not just the motor copper losses, but loss in the entire system wiring loom, introducing weight, space, and cost savings.

Typically, 800-V systems also move from silicon-based IGBTs to silicon-carbide (SiC) MOSFETs. SiC devices provide much higher switching speeds and thus lower switching losses. As a result, the operating frequency will increase, which further reduces motor losses due to reduced harmonic currents.

Lower weight improves handling and acceleration, valuable in the high-end sports car market. Together with reduced losses, it improves range, which directly relates to battery and therefore vehicle cost. Liberated space can be used to increase the size of the battery pack and, in turn, the range, or it can be allocated to increased passenger cabin space. Want a larger trunk? Smaller motors help there, too. It’s worth noting that a larger battery pack also will increase the charging time, but 800 V helps as well.

Reduced weight, volume, and losses create options for vehicle designers balancing cost, performance, and range for specific market segments. Reduction in costs makes the solution more accessible to the mid-range consumer market, not just high-performance vehicles.

Range is one of the key items when considering the switch to electric vehicles. For some, it’s a matter of convenience, and a desire to make long journeys easier. For commercial vehicles, extending the range means more efficient delivery routes, more time out on the road, fewer vehicles to cover the same area, and better operating costs.

800 V Enables Reduced Charging Time

Charging time is a challenge for consumers, as well as commercial vehicles. For urban drivers and commuters, overnight charging at home is often enough. However, planning a longer trip, especially if it exceeds the range of the vehicle, means also planning a route that provides charging stations at appropriate times.

Though chargers are typically placed with amenities nearby, it’s still undesirable to have to wait. For commercial vehicles the issue is more complicated: Returning to the depot to recharge, or having the vehicle sit idle for 90 minutes while it charges in the field, cuts into productivity and directly impacts the business’s bottom line.

How does an 800-V architecture help? As we have noted before, doubling the voltage cuts the current in half for the same power. During charging, heat dissipation is a limitation both for the charging cable and the vehicle charger inlet and internal wiring.

Moving from 400 V to 800 V allows for doubling of the charging rate for the same losses. This has several benefits. The first is straightforward—reduced charging time. If the charging power is doubled, it will take half the time to recharge, though in practice the improvement is less. Not so obvious is utilization of charging stations. If the dwell time of a charging vehicle is half, then double the number of vehicles can utilize a given charger.

Both Porsche and Kia have new all-electric vehicles whose range is starting to approach the median range for gas cars, and with charging times more comparable to refueling at a gas station with a quick stop to pick up supplies. The newest range of charging stations deployed have a 400-kW maximum rating, which is more than enough for the 800-V architecture.

Porsche’s fully electric sports car, the Taycan, has a range of 420 km (260 miles). It uses the 800-V battery architecture and can charge from 5% to 80% in just 22.5 minutes on a fast-charging station at 300 A (240 kW). It’s still capable of using 400-V charging stations, which would take around 90 minutes. Kia announced its EV6 800-V-architecture car, which charges from 10% to 80% in just 18 minutes using a maximum power of 239 kW, with an extended range version that reaches 480 km (300 miles).

Fast charging times make a crucial difference to commercial vehicles that can have a quick charge to extend their working day and delay a return to the depot for a full charge until the evening. Importantly, these faster charging times also fit into the 30- to 40-minute mandated rest periods in many regions.

800-V Adoption Has Been Faster than Expected

The automotive market has adopted the 800-V architecture faster than was initially anticipated. Porsche led the way, but it’s not just sports cars—Kia and several China manufacturers now offer 800-V vehicles. As is typical for the automotive market, innovations start in the higher-end vehicles and slowly work their way down to the mass market as the technology becomes more affordable. The benefits offered by 800-V systems include cost savings that the mid-range consumer market can utilize much sooner than was first thought.

As the automotive market embraces the 800-V architecture, we will undoubtedly see companies pushing the benefits of higher-voltage systems even further. These benefits scale up—thus, 900 V and beyond can increase these further, pushing range, weight, and charging times even more. The infrastructure will need to keep pace; the new 400-kW charging stations are already enabling this direction.

Design Considerations for the Power Solution in an 800-V System

High-voltage connected subsystems in an EV typically require a high- to low-voltage power supply. The increase to 800 V requires much higher isolation and voltage ratings.

An EV battery pack consists of many individual cells connected in a series/parallel combination. Each individual cell operates over a voltage range of 3.1 to 4.2 V. For a nominal 800-V system, there are approximately 198 cells in series, giving an overall pack voltage of 610 to 835 V.

An additional 20 to 30 V are typically added due to voltage rise during regenerative braking, giving a maximum voltage of 865 V. The power-supply internal switch must be rated significantly above this voltage. For a flyback converter, an additional 150 to 200 V must be added, giving a switch stress of 1065 V. Applying the usual 20% derating yields a specification of at least 1.33 kV.

Another important design consideration is the need for a low-voltage startup, typically 30 to 40 V. The vehicle safety systems need to power-up first, to make sure all of the control electronics are operational before anything can start to move, or faults potentially occur. Designing a power supply that runs from 30 V to >900 V can be challenging.

New High-Voltage Solutions

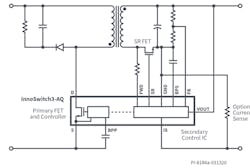

On this front, Power Integrations (PI) added two new AEC-Q100-qualified, 1700-V-rated ICs its InnoSwitch 3-AQ family. They help solve the design challenges for 800-V systems, bringing a host of features needed in the automotive space and a path to higher voltages for future designs (Fig. 1).

This simple flyback converter design integrates the SiC switch and both primary and secondary controllers. InnoSwitch3-AQ ICs use FluxLink for isolation, allowing the secondary controller to be the main controller. This unusual architecture means the secondary side determines when to switch the primary, enabling synchronous rectification without the usual drawbacks, such as incorrect switching time, and covering fault conditions.

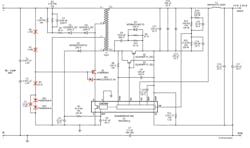

InnoSwitch3-AQ has a 30-V startup, critical to powering up the safety systems in automotive applications. Discrete solutions require additional components on the primary side to make the 30-V startup possible, which comes at quite a cost. Every component attached to the high-voltage rail must be tested for several failure modes, so PI’s higher integration helps in terms of system savings, reducing tests cases by up to 50% (Fig. 2).

Part-count reduction is crucial in EVs. Fewer parts results in a reduced failure rate due to the parts themselves, but also fewer solder joints, increasing reliability. Board area savings are even more significant, reducing weight and increasing power density, as well as creating more interior space.

The unique architecture of the InnoSwitch3-AQ IC allows it to sit across the isolation barrier, on an area of the PCB that can’t usually be populated. In practice, it could be placed underneath the transformer. This design doesn’t consume PCB space, which makes a meaningful difference to designers.

Tight output regulation eliminates the need for extra dc-dc converters to produce additional rails; they can be provided. Due to the FluxLink architecture and ±2% regulation, it only takes two switching cycles to get from zero load to full load and slew the power delivery from zero to maximum (Fig. 3). This means the output capacitors also are much smaller. With efficiency over 90%, heat dissipation is reduced enough to eliminate the need for an external heatsink. These features create further reductions in size, space, and component count.

No-load power consumption isn’t often a critical parameter, but for an EV, where the battery is always connected, this could drain a parked vehicle’s battery. The <15-mW no-load consumption offered by the new InnoSwitch3-AQ parts ensures a passenger returning to their car at an airport won’t be stranded.

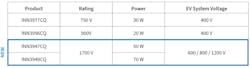

With the addition of the new 50- and 70-W output devices, the InnoSwitch3-AQ family offers solutions for EV designs using 400 V, 600 V, 800 V, and beyond (see table).