Four New Battery Varieties Highlight Toyota’s BEV Roadmap

This article is part of the TechXchange: EV Battery Management.

What you'll learn:

- Details on production estimates for the Toyota's new BEV facility.

- The three liquid-electrolyte battery types under development.

- Breakthrough that led to an advanced solid-electrolyte battery which is also under development.

Toyota aims to create a niche for itself in the mercurial business environment for electric vehicles (EVs). To achieve that goal, the company recently announced a new battery-electric-vehicle (BEV) factory that will begin production of models in 2026. These vehicles will be powered by a range of new batteries. Details have been released on four next-generation batteries consisting of both liquid- and solid-electrolyte battery technology.

Takero Kato, president of the new production facility, indicated that these next-generation models will account for 1.7 million of the 3.5 million BEVs expected to be sold globally by Toyota by 2030. He also highlighted how a range of battery technologies will be key to appealing to a wider customer base.

“We will need various options for batteries, just as we have different types of engines. It is important to offer battery solutions compatible with a variety of models and customer needs,” said Kato.

Improved Performance in Liquid-Electrolyte Batteries

The batteries that Toyota needs are coming. Liquid electrolytes are the current mainstream battery technology for BEVs. Toyota is working on improvements including higher energy density, cost competitiveness, and faster charging speeds.

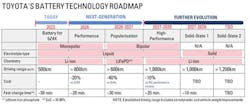

Three main battery types are under development: Performance, Popularization, and High Performance:

Performance Batteries

Performance (lithium-ion) batteries are planned for introduction in conjunction with the next-generation Toyota BEVs from 2026. The Performance battery will increase driving range to more than 800 km (497 miles) when combined with improved vehicle aerodynamics and reduced vehicle weight.

This battery is also expected to offer a 20% cost reduction compared to the current Toyota bZ4X EV crossover as well as a rapid recharging time of 20 minutes or less for 10% to 80% state of charge (SOC).

Popularization Batteries

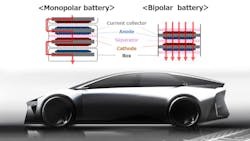

Toyota is developing Popularization (lithium iron phosphate) high-quality, lower-cost batteries to give customers a range of options, similar to the choice they have today with different powertrains. The Popularization battery is constructed using the bipolar technology the company pioneered for its nickel-metal-hydride (NiMH) batteries, combined with inexpensive lithium iron phosphate (LiFePo) as the core material.

In bipolar NiMH batteries, a cathode is applied to one side of a metal component called a current collector and an anode to the other. Several of these structures, which are known as “bipolar electrodes,” are stacked together to form a battery.

Toyota expects the Popularization battery to reach the market in 2026-27. Benefits include a 20% increase in driving range compared to the current Toyota bZ4X, a 40% reduction in cost, and a fast recharging time of 30 minutes or less for a SOC of 10% to 80%.

High-Performance Batteries

Toyota is also developing a High-Performance (lithium-ion) battery that combines its bipolar structure with lithium-ion chemistry and a high-nickel cathode to achieve a driving range capability of more than 1,000 km (621 miles) when combined with improved aerodynamics and reduced vehicle weight.

The High-Performance battery promises a further 10% reduction in cost compared to the Performance battery, and a rapid charging time of 20 minutes or less for a SOC of 10% to 80%. Market introduction is planned for 2027/28.

Breakthrough in Solid-State Batteries

Solid-state batteries have long been regarded as a potential game-changer for battery-powered EVs. Toyota claims to have made a breakthrough in its quest to improve the durability of this technology.

Toyota said its solid-state lithium-ion batteries have a solid electrolyte that allows for faster movement of ions and a greater tolerance of high voltages and temperatures. These qualities make the batteries suitable for rapid charging and discharging, as well as for delivering power from a smaller form factor.

Until now, the tradeoff has been an expected shorter battery life, but Toyota’s recent advances are said by the company to have overcome this challenge. Toyota has moved its focus to bringing solid-state batteries into mass production. The aim is for the batteries to be ready for commercial use by 2027/28.

The technology was initially slated for introduction in hybrid electric vehicles (HEVs), but now the company’s primary focus is on its use in next-generation BEVs.

Toyota’s first solid-state battery is expected to come with a 20% increase in driving range compared to the Performance battery (approx. 1,000 km/621 miles) and a fast charging time of 10 minutes or less for 10% to 80% SOC.

Toyota already has a higher specification Li-ion solid-state battery under development, targeting a 50% improvement in cruising range compared to the Performance battery.

Optimizing Battery Height to Boost Range

Aerodynamics plays a key role in determining the driving range of all vehicles. Consequently, Toyota’s quest to maximize the range of its BEVs begins with a focus on reducing or optimizing the vehicles’ drag-coefficient (Cd) rating.

Toyota took this a step further by concentrating on CdA—the drag coefficient multiplied by A, the vehicle’s frontal area—as the multiplication effect of the frontal area has a much greater bearing on range capability.

The height of the battery is central to Toyota’s thinking. Typically, the battery is located beneath the vehicle floor, which can increase the vehicle’s overall height. This, in turn, will have a multiplier effect on the CdA, and thus on the vehicle’s range performance.

However, if the battery’s height can be reduced, then it follows the vehicle’s overall height can be lowered, CdA can be improved, and ultimately, it will increase overall range.

The battery pack in today’s Toyota bZ4X is around 150 mm (about 6 inches) high. Toyota plans to reduce battery height to 120 mm, and to 100 mm in the case of high-performance sports models where a low hip-point is also desirable (the hip-point is the theoretical relative location of a driver’s hip in a vehicle).

Read more articles in the TechXchange: EV Battery Management.