Eliminate Resistive Cabin Heating in Electric Vehicles

Members can download this article in PDF format.

What you’ll learn:

- Significant impact of EV cabin heating on EV range.

- Improvements to resistive heating.

- Alternatives to resistive heating.

Beyond the basic efficiency of electric propulsion, physics isn’t always kind to electric vehicles (EVs). Indeed, one of the most significant operational challenges for EVs is temperature management of numerous components such as permanent magnets, batteries, motors, and power electronics, all of which have a preferred range of operating temperatures. Many kinds of sensors, both active and passive, are employed to meet those systems requirements.

But in many parts of the world, the most challenging temperature control problem is providing sufficient heat to keep windows defrosted and vehicle inhabitants reasonably comfortable. It’s a challenge that relies on sensor technology as well as a growing list of approaches to generating heat.

Resistive heating—simple and reliable—has been the chosen means of delivering warmth for most EVs on the market. Resistive heating devours energy, though, and can easily halve the range of an EV. In some cases, the impact may be even more severe.

Searching for a Resistive-Heating Alternative

That fact has engineers eyeing additional or alternative means of keeping cabins cozy, even perhaps burning hydrocarbons to help preserve battery life!

Currently, the default resistive-heating solution is the positive temperature coefficient (PTC) resistive heater. Rather than relying on fixed-resistance metal coils as a heating element, PTC heaters employ a variable resistance semiconductor thermistor to generate heat. The semiconductor properties have the benefit of yielding a roughly stable temperature output, which could effectively be increased or decreased via air circulation or a separate thermostat.

Conveniently, PTCs can be created in many shapes and form factors; materials are typically ceramic or polymer. To achieve maximum effectiveness, delivering heat where it’s really needed, resistive PTC heating is often used in EV seats and even steering wheels, where it can directly warm occupants with minimal waste. Sensors and intelligence further ensure that PTCs deliver exactly the heat needed, without further waste of energy.

However, particularly for larger vehicles, PTCs haven’t necessarily been adequate. A Vermont transit organization, in its report on testing EV buses, admitted it was forced to add a combustion-based heating system to the vehicles to keep their range from degrading too significantly. And even with that boost, some vehicles had to be taken out of service during the coldest months.

EV Combustion Heaters

Unsurprisingly, many solutions on the market harness combustion to keep occupants and even batteries and drivetrains at an optimal temperature while also providing critical defrosting functions to ensure visibility. Auxiliary, combustion-based heaters have been available since the earliest years of the automotive age.

Indeed, one of the better-known manufacturers, Eberspächer, started manufactured preheaters for Volkswagen Beetles in the mid-20th century. Based in Germany with North American operations in Mississauga, Ontario, Canada, the company provides fuel-operated heating solutions that can run on diesel, gasoline, ethanol, and bio-ethanol. These combustion heaters can deliver between 1.3 and 5.6 kWh at 80% efficiency, a heat output that would tax even large battery packs.

Still, the need to separately fuel combustion heaters, the additional complexity they bring, and the desire to live up to the zero-carbon goals of the EV community has designers looking deeper for solutions.

With that concern in mind, engineers and researchers are starting to consider alternatives that might be less power-hungry. The most obvious, and one already in use by many EV makers, including Tesla, is the heat pump.

Heat Pump Potential

Not only are heat pumps very efficient, they also have a significant range of heat output and, of course, can potentially be used to provide cooling (a separate subject). Unfortunately, some of the advantages begin to evaporate when temperatures decline. Below zero Celsius, power consumption begins to rise significantly. And at even colder temperatures, it becomes difficult to continue to generate sufficient warmth for passengers, meaning PTC resistance heaters are still often required as backup.

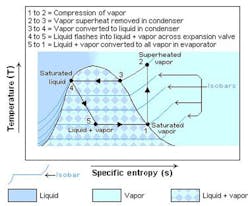

However, there are some indications that heat-pump performance can be significantly improved. Its “efficiency” in terms of the task of heating derives from its ability to extract energy from the ambient environment. So, the energy expended to operate the heat pump is effectively multiplied in the output it creates.

Different refrigerants are the starting point for further improvement (see figure). Ozone-depleting chlorofluorocarbons such as R-12 and R-22 are long gone. Many successor products are kinder to the ozone, but they tended to have high global warming potential (GWP) when they find their way into the atmosphere.

Further low-temperature performance boosts could come from hydrocarbon “refrigerants” such as propane and butane. They perform especially well at low temperatures, and if released into the atmosphere, are less problematic than chlorofluorocarbons (CFCs), hydrochlorofluorocarbons (HCFCs), hydrofluorocarbons (HFCs), and hydrofluoroolefins (HFOs) in terms of their GWP. Of course, both are more familiar as highly inflammable fuels, which makes them potentially risky for heat-pump applications, especially in the confined environment of an EV.

Ammonia, familiar from large, industrial refrigeration applications, is also getting a look, but its potential toxicity poses challenges, too. Still, getting big improvements in heating with much less expenditure of energy would be a big step toward making EVs practical.

Other components in an EV heat-pump system are also capable of improvements, such as compressors that can deliver higher pressures while using less power and/or compressors that better adjust output to demand. Finally, potential material choices and other minor improvements may move the needle a bit on the performance of heat exchangers.

Harvesting Waste Heat

Related to heat pumps is the potential to harvest waste heat from vehicles systems, either directly or integrated with a heat-pump system. The complexity here, for which sensors are vital, is the need to maintain proper temperatures for all of these systems, something that’s usually done through a WEB circulation system. This could be tapped for cabin warmth, but in cold conditions, it would need to avoid taking too much energy.

In all of these approaches to heating and/or cooling, knowledge is literally power. In other words, sensors and intelligence are essential. Efficient operation must be ensured, thereby contributing substantially to vehicle performance. Safety is also a factor at every stage.

So, EV passenger comfort must be considered within a broader environment, and its complexity recognized. That complexity is the key to achieving the cumulative performance breakthroughs needed to keep consumers happy and ensure a long future for EVs.

References

“Hyundai/Kia’s EV Heat Pumps a Benchmark for Other Brands,” Hyundai Motor Group.

“Sensing to solve EV thermal challenges,” SAE International.

About the Author