Buck-Boost Controller Answers Call for Redundant Battery Systems

Because safety-critical systems must work if there’s a power interruption of any kind, the next generation of self-driving vehicles can be expected to borrow a page from the commercial aviation industry: Provide redundancy not only for sensors and computer chips, but for the electrical architectures as well. That includes batteries, regardless of whether a 12- or 48-V system (or both) is in the powertrain.

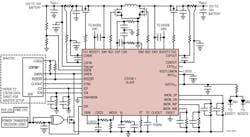

To meet the need for redundancy, Analog Devices developed the LT8708-1. The 98% efficient bidirectional buck-boost switching regulator controller operates between two batteries with the same voltage, thus preventing system shutdown should one of the batteries fail. When the input voltage goes away, the load maintains power without disruption from the battery (or supercaps) by way of the part’s bidirectional capability.

The LT8708-1 operates from an input voltage that can be above, below, or equal to the output voltage, suiting it for two 12-, 24-, or 48-V batteries commonly found in electric and hybrid electric vehicles. The LT8708-1 will also work in 48-V/12-V and 48-V/24-V dual-battery systems.

To add power and phases, the LT8708-1 can be used in parallel with the company’s LT8708. The LT8708-1, which always operates as a slave to the master LT8708, can be clocked out-of-phase and has the capability to deliver as much power as the master.

This 80-V synchronous 4-switch buck-boost dc-dc controller enables six independent forms of regulation: VIN current (forward and reverse); VOUT current (forward and reverse); and VIN and VOUT voltage.

One or more slaves can be connected to a single master, proportionally increasing the power and current capability of the system. The master controls the overall current delivered by the multiphase system. For example, the LT8708 controls the VIN and VOUT regulation voltages through its FBIN and FBOUT pins.

The LT8708-1 has the same conduction modes as LT8708: continuous conduction mode (CCM), discontinuous conduction mode (DCM), hybrid conduction mode (HCM), and burst mode. This allows the LT8708-1 to conduct current and power in the same direction(s) as the master. The master controls the overall current and voltage limits for an LT8708 multiphase system, and the slaves comply with these limits.

The operating mode of the controller is determined through the MODE pin. Forward and reverse current can be monitored and limited for the input and output sides of the converter. All four current limits (forward input, reverse input, forward output, and reverse output) are able to be set independently using four resistors. In combination with the DIR (direction) pin, the chip can be configured to process power only from VIN to VOUT or only from VOUT to VIN, as needed.

The LT8708-1 operates with a single inductor over a 2.8- to 80-V input voltage range and can produce an output voltage from 1.3 to 80 V. It will deliver up to several kilowatts of power depending on the choice of external components and number of phases.

To help designers, Analog Devices offers its demonstration circuit 2596A to evaluate the performance of the LT8708. The demo-board input range is 36 to 75 V. The output voltage is set at 48 V and the output current limit at 6 A.

The LT8708-1 comes in a 5- × 8-mm QFN-40 package. Three temperature grades are available, with operation from –40 to 125°C for the extended and industrial grades, and a high temp automotive range of –40 to 150°C.