Simplify Isolated CAN, Power Interfaces for HEV 48-V Systems

Designing for today’s automobiles is a balancing act. Between meeting increasingly strict emissions standards and powering the growing number of on-board systems and gadgets, today’s vehicles need to be as efficient as they are high-powered.

To achieve this convergence of efficiency and power, engineers are relying more heavily on systems that combine 48-V electric power operation with conventional gas engines, as with hybrid electric vehicles (HEVs). This approach ensures that vehicles meet strict carbon-dioxide (CO2) emissions while also improving performance and drive quality.

While much has been said about dual-battery automotive systems themselves, I would like to focus on a critical and sometimes overlooked component in these combined 12- and 48-V systems: galvanic isolation. Galvanic isolation is used for immunity against ground noise and to protect 12-V systems in case of ground lifts or fault conditions in the 48-V systems to which they connect.

In this article, I will discuss the need for isolation in 48-V automotive applications, and describe a compact, efficient, robust and low-noise method for isolating 48-V systems through the control area network (CAN) interface.

The Need for Galvanic Isolation in Vehicles Using 48-V Batteries

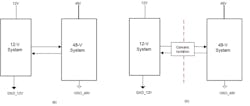

Even in vehicles that use a 48-V battery (usually lithium-ion), a conventional 12-V lead-acid battery still powers control electronics and lower-power devices. Systems running on these two supplies need to communicate with one another. For example, a 48-V starter generator is controlled by the engine controller operating off the 12-V battery. The grounds of both systems connect to the car chassis. While, theoretically, the two systems can directly connect to each other (Fig. 1a), galvanic isolation (Fig. 1b) is almost always necessary because of these reasons:

- Transient ground potential differences: The grounds of 12-V systems connect directly to the car chassis using bolts. The grounds of 48-V modules connect to the car chassis using cables that can be a few feet long. The high amount of switching currents present in 48-V systems such as the starter generator or ac compressor, combined with the inductive nature of the ground cable, may result in transient ground noise that can easily corrupt low-voltage 3.3-V or 5-V communication signals. Galvanic isolation is necessary to ensure reliable data transfer.

- Ground lift on the 48-V side: Sometimes under fault conditions or during maintenance, the GND_48V in Fig. 1a could disconnect from the chassis. The 48-V supply to the module, which in turn is connected to the 48-V battery, may still be intact. In this situation, all internal nodes of the 48-V system, including the interface to the 12-V system, can float up to 48 V. This poses a danger to 12-V systems, since its input/output ports may not be designed to handle 48 V. In Fig. 1b, this same fault condition doesn’t stress the 12-V system. The 48 V appears across a galvanic-isolation barrier that’s usually rated for much higher voltages (like 2.5 kV).

- Short-circuit conditions: In Fig. 1a, any short circuit inside the 48-V system can result in the 48 V appearing at the interface to the 12-V system. This potential hazard can jeopardize many circuits operating on the 12-V supply, including those critical to the safe operation of the vehicle. Galvanic isolation can help ensure that any short circuits on the 48-V system don’t propagate to the 12-V side of the vehicle.

1. Direct and galvanically isolated connection between 12- and 48-V systems.

Isolating 48-V Systems Using the CAN Interface

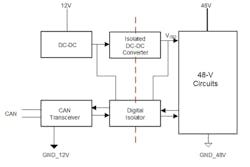

It’s possible to achieve galvanic isolation in multiple ways, with the isolation boundary drawn at different locations inside the system. Fig. 2 shows a popular approach that achieves isolation at the CAN interface. Isolating at the CAN interface versus elsewhere in the system has the benefit of using the least number of isolation channels—just two channels of isolation are sufficient. This reduces cost and board space.

2. Shown is an example of galvanic isolation between the 12- and 48-V sides in a mild hybrid electric vehicle.

An isolated dc-dc converter derives an isolated power supply, VISO, that powers parts of the 48-V system. VISO ensures that the digital isolator and critical parts of the 48-V system have power available for operation, even if the 48-V battery is fully discharged. VISO can also be used to put the 48-V side into a safe state in case GND_48V disconnects.

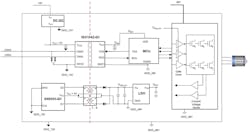

New integrated isolated CAN transceivers and isolated dc-dc power-supply controllers are now available that help simplify the isolated CAN interface in 48-V systems. Fig. 3 shows an example 48-V starter generator. You can use similar isolation architectures for other 48-V systems, such as dc-dc converters, battery-management systems, heaters, and air compressors.

3. This 48-V starter-generator uses an isolated CAN transceiver with a push-pull isolated power supply.

Single-chip integrated isolated CAN transceivers such as Texas Instruments’ (TI) ISO1042-Q1 (Fig. 3, again) integrate high-voltage galvanic isolation with a high-performance CAN transceiver to help reduce board area while improving timing parameters. From the CAN point of view, low loop delays and skews enable high-speed data communication using CAN Flexible Data-Rate. Isolation provides immunity against conducted and radiated disturbances. Redundant or reinforced isolation will supply extra margin for protection under fault conditions.

When used with an external transformer, a push-pull transformer driver like TI’s SN6505-Q1, also shown in Fig. 3, can generate an isolated power supply, VISO_HV, (in the range of 10 to 15 V) to power metal-oxide semiconductor field-effect transistor (MOSFET) gate drivers, and a lower VISO (in the range of 3.3 to 5 V) to power the microcontroller and digital side of the isolated CAN device.

The push-pull topology uses two low-side switches that are on in alternate clock phases to transfer power continuously across a center-tapped isolation transformer. The topology employs feed-forward regulation, with the output voltage controlled purely through transformer ratios. Continuous power transfer results in much lower peak currents compared to other topologies, leading to lower emissions and higher efficiency. The symmetric drive also prevents transformer saturation, resulting in compact transformers.

On the 12-V side, a non-isolated dc-dc converter or buck can generate a 5-V supply to supply the CAN transceiver, while also serving as the input voltage for the push-pull isolated dc-dc converter. Using a buck up front makes the system insensitive to variations in the 12-V battery power supply that can be caused by load changes. Also, operating with a lower input voltage (5 V vs. 12 V) results in smaller transformers.

Conclusion

Galvanic isolation is a very important consideration in automobiles using 48-V battery power. Isolation is used for immunity against ground noise, as well as to protect 12-V systems in case of ground lifts or fault conditions in the 48-V systems to which they connect. Examples of systems that use 48-V power in HEVs include starter-generator, electric turbo chargers, electric pumps, air conditioners, heaters, electric suspension, and driver assistance. Integrated isolated CAN transceivers, combined with push-pull-based isolated dc-dc power supplies, provide a compact, efficient, robust, and low-noise technique for isolating 48-V systems.

Anant Kamath is a Systems Engineer at Texas Instruments.

About the Author

Anant Kamath

Systems Engineer

Anant Kamath has been a systems engineer with Texas Instruments since 2002. He graduated with a Bachelor of Technology in Electrical Engineering from the Indian Institute of Technology, Madras, India. In his current role, Anant is responsible for definition and application support for industrial and automotive high-voltage isolation products. His work also includes product compliance to component and end equipment standards that deal with isolation, electrical safety, and EMC.