An Introduction to Hybrid-Electric Aircraft (Part 3)

What you’ll learn:

- The first commercial aircraft featuring hybrid-electric propulsion systems should be taking their maiden flights in late 2025, offering their operators reductions in fuel consumption and operating costs of 40%-70%.

- Although initially limited to small commuter aircraft, at least one company is already testing prototypes of a larger hybrid aircraft suited for regional services, scheduled to enter production within the next 3-5 years.

- Several ventures are already underway to offer conversion kits for existing commuter-class and regional airliners.

As we’ve seen in Part 1 and Part 2 of this series, hybrid-electric propulsion systems promise to give the electrification of the world's air transportation networks a flying head-start (pun intended). They make it possible to use the relatively low power densities of today's batteries to produce practical aircraft that enjoy significantly lower carbon emissions and operating costs. But when Part 1 was originally posted nearly a year ago, there was still some question about whether the technologies could mature quickly enough to become commercially viable.

During that unplanned delay, those questions were put to rest as the technology matured rapidly and several more companies entered the hybrid-electric market space. We now have a surprising number of viable aircraft designs whose prototypes are undergoing flight tests in preparation for certification and commercial production within the next two to five years.

The designs closest to commercialization are smaller commercial aircraft, ranging from six to 10 passenger commuter/cargo vehicles to regional airliners capable of carrying 20 to 40 passengers (Fig. 1). There are also a few promising longer-term projects to identify the technologies and architectures needed to develop larger, more long-legged aircraft that will help pave the way for the succeeding generation of all-electric airliners.

Hybrid Commuter Craft Fill the Short-Haul Gap

While sexy-looking eVTOL “air taxis” have captured the public’s (and many investors’) attention for nearly a decade, their high costs, limited range, and myriad other issues have delayed even the most promising vehicles’ market entry while restricting many of them to address a relatively narrow range of applications.

As all-electrics stumbled, several new companies jumped in to support NASA's proposed Regional Air Mobility Initiative. It’s intended to encourage the development of a regional air transportation network that makes use of many of the nations' smaller metropolitan, suburban, and rural airports.

Electra Aero

One of the leaders in the race to bring a practical hybrid to the short-haul/commuter market is Electra Aero. Its nine-passenger hybrid e-STOL commuter aircraft is designed to fill a gap in transportation between 50 to 500 miles, bringing air service to thousands of communities where air travel today isn’t a practical or affordable option.

>>Download the PDF of this article, and check out the other parts of this series

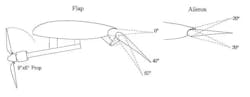

The company does this using a combination of series-type electric propulsion and a "blown lift"2 short take-off and landing (STOL) system. The blown-lift system consists of a series of electrically driven propellers distributed across an aircraft's wing with specialized flaps that enable it to capture the propwash and translate it into lift (Fig. 2).

Electra Aero has already put the EL-2 Goldfinch, an 80% scale technology demonstrator, through a rigorous test program and has proven the basic feasibility of its technologies, which will be used in a full-scale production prototype that’s already under development. Its EL-2 took to the skies for the first all-electric test flight on November 11, 2023, and completed its first flight operating in hybrid-electric mode on November 19. Since then, the EL-2 has successfully completed off-runway test flights, operating from a small grass field near Electra’s facility in Manassas, Va. (see video below).

Following the success of the EL-2, Electra is preparing a full-scale production prototype of the EL9, a nine-passenger air taxi/cargo craft for testing later this year. With an anticipated cruising speed of 200 mph, it’s expected to use 40% less fuel than today's commuter aircraft on a typical 100-mile route.

The production prototype's batteries will be supplemented by a 600-kW electric turbogenerator propulsion system, manufactured by Safran Helicopter Engines, which will provide enhanced power for takeoff and serve as a range extender for missions of up to 500 miles (with 45-minute reserve). Based on initial tests, Electra estimates its production craft will be able to safely operate from airfields as short as 300 feet (Fig. 3).

Demand for Electra's hybrid commuter craft appears to be strong, with roughly 2,200+ aircraft pre-orders and options already placed by over 35 operators. While it’s unlikely that all of the pre-orders will translate into actual sales, expectations that there would be sufficient demand enabled the company to successfully complete a $115 Million Series B funding round. The funding is intended to finalize the design of the EL9 and establish commercial manufacturing operations.

Retrofits to the Rescue

In addition to several other clean-sheet designs, a lot of activity involves modifying existing certified conventional aircraft with hybrid-electric propulsion. Instead of reinventing the wheel, using a proven airframe greatly reduced development time and cost. It enabled engineers to focus the majority their efforts on developing the technology behind the propulsions systems that will power tomorrow's aircraft. Time-to-market is also shortened by simplifying the usually lengthy process of obtaining government airworthiness certification

For example, at least two projects are underway to re-power Cessna's venerable Model 208 "Caravan" utility aircraft with a hybrid-electric system. The solution that appears to be closest to market is a retrofit kit, developed by Ampaire. It will allow operators to swap the 208’s Pratt & Whitney PT6 for a hybrid diesel-electric system that will burn 50% to 70% less fuel and cut hourly operating costs by up to 40% (Fig. 4).

NOTE: The fourth and final installment of this series will include additional details on the two hybrid Cessna 208 projects currently underway, plus several other important hybrid-electric conversion projects. Stay tuned…

Hybrid Power for Regionals

Moving further up the aero-food chain, several significant projects are being conducted to develop hybrid propulsion systems for use in both new and existing type-certified regional-class airframes. Since turboprops already enjoy an efficiency advantage over jets for shorter distance (100-400 miles) missions, they could provide momentum for commercial retrofits of existing airframes that serve as an economical "bridge" technology until all-electric propulsion becomes more practical.

Heart Aerospace’s ES-30

One of the most notable developments in the hybrid-electric market space is Heart Aerospace’s ES-30. The 30-passenger airliner is a clean-sheet design developed to address both ambitious global emission targets and the stringent economic challenges facing operating regional air services (Fig. 5).

The ES-30 is powered by a pair of small turboprop engines mounted outboard and two electric motors inboard. During takeoff, the craft uses both power systems, which enable it to take off from fields as short as 1100 meters. Once at cruise altitude, the pilot can shut down its turbines for up to 200 km of all-electric cruise. Its turboprops can be switched on to support flights as long as 800 km.

The ES-30’s batteries can be recharged in 30 minutes and are carried in easily swappable modules that form part of the fuselage. Besides providing quick access for service, the modules can be easily swapped as battery technology improves.

In late 2024, Heart unveiled a full-scale all-electric demonstrator craft, dubbed the Heart X1, which was built at its Gothenburg, Sweden facility. Heart said that the X1 will initially be used for ground-based testing, focusing on charging operations, taxiing, and other procedures, with its first flight anticipated to occur sometime in late 2025 at its Plattsburg, N.Y. facility. The X2, a full hybrid version of a demonstrator airframe, is already under construction and expected to make its maiden flight in 2026.

A longer, more detailed tour of the X1 can be viewed by clicking on this link.

BONUS: If you want to get a feel for what it would be like to fly the ES-30, Microsoft’s Flight simulator supports a very realistic model of aircraft, which includes its flight characteristics and the operating details of its unique hybrid-electric propulsion system. Follow this link for a walk-through of the simulation.

Heavy Hybrids on the Horizon

At the time of this article, most significant efforts for the commercialization of hybrid technologies for larger (100+ seats), longer-legged (1000+ miles) airliners are in their very early stages. Due to their higher complexity, cost, and risk, the timelines for these projects are typically measured in decades and often being undertaken as public/private partnerships with NASA, DOD, or other federal agencies.

If NASA’s R&D budget doesn’t fall victim to the turbulent politics of the present administration, the aerospace industry will continue to benefit from its work in advanced hybrid-electric propulsion technology. Similar to how the federally funded agency helped develop some of the technical developments that enabled the emergence of jet aircraft in the 1950s, NASA has been addressing some of the longer-term issues needed to make electric aviation a reality.

Although several airframe manufacturers appear to be working with NASA with early-stage studies for large hybrid-electric aircraft, they’re very reluctant to share any significant technical details about their work. We can, however, infer a lot about the types of technologies and strategies they’re using from publicly funded R&D efforts undertaken by NASA and other aerospace organizations.

NASA's SUSAN

Built to carry a maximum of 180 passengers with a 750-mile economic range and a 2,500-mile design range, NASA’s SUbsonic Single Aft eNgine (SUSAN) Electrofan is product of the Single-Aisle Turboelectric Aircraft with Aft Boundary Layer Propulsion (STARC-ABL) program.

Like the STARC-ABL concept vehicle, SUSAN is a hybrid-electric aircraft with a single tail-mounted turbofan engine that provides thrust and power to 16 electric propulsors located on the wings. This configuration uses large-scale power extraction along with a high-power electrical system transmitting 20 MW of power from the engine to the wing propulsors. NASA says that SUSAN's goal is to reduce emission levels by 50% within the next few decades.

Other NASA Hybrid Aircraft Projects

NASA has been investigating several other electrified propulsion systems for aircraft, including fully turboelectric, partially turboelectric, and parallel hybrid-electric systems, including the N3-X concept shown in Figure 6.

Though never intended for direct commercialization, the 300-passenger, hybrid wing body concept showcases a collection of design techniques and technologies that would enable it to meet NASA’s goal of a commercial airliner that achieves a 70% fuel burn reduction per-passenger-mile. The blended wing achieves a very high lift-to-drag ratio, which when combined with the higher propulsive efficiency of the engine’s high fan bypass ratio and improved boundary layer ingestion, could enable it to fly as far as 7,500 nmi between fueling stops.

References

1. Antcliff, Borer, Sartorius, et al., "Regional Air Mobility: Leveraging Our National Investments to Energize the American Travel Experience," NASA Langley Research Center, January, 2021, Document ID# 20210014033.

2. Christopher B. Courtin, R. John Hansman, Mark Drela, "Flight Test Results of a Subscale Super-STOL Aircraft," MIT, January 2020, International Center for Air Transportation (ICAT), Report No. ICAT-2020-01.

>>Download the PDF of this article, and check out the other parts of this series

Next in This Edition of PowerBites

More PowerBites

About the Author

Lee Goldberg

Contributing Editor

Lee Goldberg is a self-identified “Recovering Engineer,” Maker/Hacker, Green-Tech Maven, Aviator, Gadfly, and Geek Dad. He spent the first 18 years of his career helping design microprocessors, embedded systems, renewable energy applications, and the occasional interplanetary spacecraft. After trading his ‘scope and soldering iron for a keyboard and a second career as a tech journalist, he’s spent the next two decades at several print and online engineering publications.

Lee’s current focus is power electronics, especially the technologies involved with energy efficiency, energy management, and renewable energy. This dovetails with his coverage of sustainable technologies and various environmental and social issues within the engineering community that he began in 1996. Lee also covers 3D printers, open-source hardware, and other Maker/Hacker technologies.

Lee holds a BSEE in Electrical Engineering from Thomas Edison College, and participated in a colloquium on technology, society, and the environment at Goddard College’s Institute for Social Ecology. His book, “Green Electronics/Green Bottom Line - A Commonsense Guide To Environmentally Responsible Engineering and Management,” was published by Newnes Press.

Lee, his wife Catherine, and his daughter Anwyn currently reside in the outskirts of Princeton N.J., where they masquerade as a typical suburban family.

Lee also writes the regular PowerBites series.