Designing for Solid-State Batteries: The Next EV Frontier

What you’ll learn:

- The state of the art for solid-state batteries (SSBs).

- How the market is trending and why preparing now for SSBs makes sense.

- Engineering tips that can support development and implementation of SSBs.

As the electric-vehicle (EV) industry races toward higher efficiency and greater range, solid-state batteries (SSBs) have emerged as one of the most promising technologies on the horizon. These advanced batteries are being hailed for their potential to deliver significantly higher energy density, faster charging times, improved safety, and a longer operational lifespan compared to traditional lithium-ion batteries.

Yet, despite their advantages, solid-state batteries remain largely in the research and pilot stage, with several technical and economic barriers preventing widespread commercialization. Still, it’s important for EV designers to grasp the potential and, more importantly, be prepared with designs that can be adapted to solid-state batteries when/if they become commercially viable.

The Cutting Edge: Who’s Leading the Charge?

A number of major players are pushing the boundaries of solid-state battery development. Toyota, for instance, announced plans to release solid-state EVs as early as 2027. The company claims its prototypes can deliver over 1,000 km of range and recharge in just 10 minutes—an ambitious leap forward that’s still undergoing real-world testing.

Meanwhile, U.S.-based QuantumScape is developing lithium-metal solid-state batteries with a ceramic electrolyte. Laboratory results are promising, indicating the ability to reach an 80% charge in approximately 15 minutes and achieve energy densities greater than 400 watt-hours per kilogram. Solid Power, supported by automotive giants BMW and Ford, launched pilot production of 100 amp-hour cells designed for vehicle integration and testing.

Other battery heavyweights like CATL, LG Energy Solution, and Samsung SDI are exploring hybrid designs that combine solid and liquid electrolytes, aiming to create a smoother transition path from current lithium-ion technology to fully solid-state systems.

What are the Breakthroughs and Innovations?

The use of lithium-metal anodes is central to achieving the high energy densities promised by SSBs. In parallel, researchers are developing a range of solid electrolytes—sulfide-based, oxide-based, and polymer-based—all of which offer distinct advantages and tradeoffs in terms of conductivity, manufacturability, and chemical stability.

>>Download the PDF of this article, and check out the TechXchange for similar articles and videos

A key technical focus continues to be dendrite suppression. Dendrites—needle-like lithium formations—can grow during charging, potentially short-circuiting batteries. Solid-state designs aren’t immune but seem to be better at controlling or even eliminating dendrite growth, offering a potential major safety advantage over conventional cells.

What are the Barriers to Mass Adoption?

Despite the breakthroughs, major hurdles remain. One of the most significant involves the materials used. While sulfide electrolytes offer excellent ionic conductivity, they’re extremely reactive with air and moisture, making manufacturing complex and costly. Interface resistance between the solid electrolyte and electrode materials can also increase over time, diminishing both efficiency and battery life.

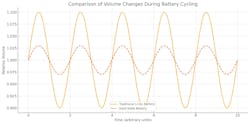

Another challenge lies in managing volume changes during battery cycling (see figure). These expansions and contractions introduce mechanical stress at the electrode-electrolyte interfaces, which can lead to cracking and eventual performance degradation.

On the production side, solid-state batteries require entirely new manufacturing infrastructure, from dry rooms to high-precision quality-control systems. Scaling up from lab to factory is a delicate and expensive process, complicated further by the materials' extreme sensitivity. Currently, production costs for solid-state batteries are estimated to be 2X to 3X higher than those of conventional lithium-ion batteries.

And while dendrites are less likely to form in solid electrolytes, they’re not entirely eliminated. Under high current densities, lithium dendrites can still penetrate grain boundaries, posing a risk of short circuits and reducing cycle life.

What are the Signs of Progress So Far?

Despite these challenges, the industry has already celebrated several important milestones. Companies like QuantumScape and Solid Power have demonstrated solid-state cells capable of more than 800 to 1,000 charge-discharge cycles in lab conditions. In addition, both have delivered multi-layer pouch cells to original equipment manufacturers (OEMs) for vehicle testing, signaling growing readiness for real-world applications. Recently, Stellantis and Mercedes announced further accomplishments.

Energy density—a key benchmark for EV battery performance—has surpassed 350 to 400 Wh/kg in prototype cells. It represents a significant improvement over the 250 to 280 Wh/kg commonly seen in current lithium-ion batteries.

What Do Electrical Engineers Need to Know?

SSBs may operate over different voltage and thermal profiles than Li-ion. As such, thermal management must accommodate potentially lower heat generation but less passive cooling (due to denser packaging), in other words, a different though potentially no less challenging problem.

These considerations arise from differences in materials, charging behavior, energy density, and safety characteristics. It’s familiar territory, but with some important new factors that can’t be ignored:

What are the Thermal Design Considerations?

Solid-state batteries typically generate less heat during charging and discharging due to lower internal resistance and reduced parasitic reactions. However, high-power applications and fast charging can still produce substantial localized heating, especially near the solid electrolyte-electrode interface.

Furthermore, SSBs can exhibit localized hot spots, especially where interface contact is poor or where current density is high. The solid electrolyte's lower thermal conductivity (compared to liquid electrolytes) can lead to heat build-up in certain regions.

These factors mean thermal-management systems (TMSs) may need to adapt. Passive cooling may suffice in some low-power SSB applications, but EVs will likely require active cooling systems (air, liquid, or phase-change materials). Cooling strategies may need to shift from bulk fluid flow to localized heat extraction (e.g., heat pipes or embedded fins).

SSBs will often have different operating temperature windows compared to existing batteries. For example, some solid electrolytes (especially sulfides) operate best above ambient temperatures (e.g., 40 to 60°C) to achieve optimal conductivity while others (e.g., certain polymers or oxides) require thermal pre-conditioning or heating elements, especially in cold climates.

What are Some Electrical Design Considerations?

To optimize voltage range and efficiency, some SSBs may operate at higher nominal and peak voltages. This may require re-engineering of inverters, DC-DC converters, and battery-management systems (BMS).

Higher energy density means that for the same pack volume, more current may be needed during high-power draw. Therefore, busbars, contactors, and interconnects must be optimized for lower resistance and minimal inductive losses.

As noted, the higher energy density and voltage could challenge existing BMS. At a minimum, new algorithms may be needed for state-of-charge (SOC) estimation and balancing. Both SOC and state-of-health (SOH) estimation algorithms must be updated, as SSBs demonstrate different voltage profiles and degradation mechanisms. In particular, monitoring needs to be more sensitive to temperature gradients, mechanical degradation (e.g., loss of interface contact), and pressure changes in the pack.

Because of insulation and dielectric requirements, high-voltage solid-state cells may require enhanced electrical isolation and improved dielectric barriers, especially when using thin solid electrolytes prone to puncture or breakdown.

Conversely, the electrode-electrolyte interface in SSBs often has higher resistance than in liquid systems, particularly if not well-bonded. As a result, the design must include uniform pressure application across cells, minimal mismatch in expansion/contraction coefficients, and, in general, the incorporation of compression frames or spring systems in module design.

Why are Compression Systems So Crucial?

Compression structures can’t be neglected. These structures are needed to maintain internal contact pressure because in solid-state batteries, good physical contact between the solid electrolyte and electrode materials is essential for efficient ion transfer. Unlike liquid electrolytes that flow to fill gaps, solid components must be pressed together to maintain low interfacial resistance.

Compression ensures continuous contact during expansion/contraction cycles, prevents delamination or gaps that can increase resistance or cause battery failure, and compensates for manufacturing tolerances or thermal expansion mismatches.

During charge and discharge, both traditional and solid-state cells experience minor mechanical expansion and contraction. Without proper pressure management, cells can crack, delaminate, or experience layer separation, which may lead to capacity fade and shorter cycle life. Compression frames or springs absorb these changes and distribute force evenly across all cells.

Finally, these structures have a role in improving structural integrity and safety since battery packs must endure vibration and shock from both road conditions and/or crashes, thermal cycling from driving and fast charging, and aging-related deformation.

References

Solid-state batteries, their future in the energy storage and electric vehicles market.

>>Download the PDF of this article, and check out the TechXchange for similar articles and videos

About the Author