E-Mobility’s Shift to a More Efficient Future

What you’ll learn:

- EV developments leading to single-pair Ethernet (SPE) and power over data line (PoDL).

- PoDL, when paired with SPE, is an emerging technology designed to address more data-centric EV requirements.

- Overvoltage and overcurrent protection requirements in PoDL.

Power over data line (PoDL) and single-pair Ethernet (SPE) represent the next steps in the automotive shift toward data-centric electric vehicles. As modern cars incorporate an increasing number of data-centric sensors and subsystems, they now generate more data than traditional designs can efficiently handle. At the same time, automakers are under pressure to reduce weight whenever possible to minimize costs.

PoDL, when paired with SPE, is an emerging technology designed to address both challenges. This article discusses the developments leading to SPE and PoDL, as well as the protection elements implemented to protect against overvoltage and overcurrent events.

Innovations Leading to SPE and PoDL

Several earlier advances have contributed to the concept of “data centers on wheels,” including zonal control, higher voltage wires, and SPE. Today’s cars face the unique challenge of communicating among numerous subsystems, with devices distributed throughout the vehicle.

The traditional domain strategy assigns each subsystem its own communication bus that runs throughout the car. While this approach offers a simpler, intuitive layout, it leads to excessive bulky wiring that runs parallel to each other, requiring long and heavy cable wraps.

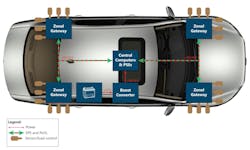

In contrast, zonal control handles the problem not by device function, but by its location (Fig. 1). Zonal control consolidates all devices in a specific area (e.g., hood, trunk, front left door) onto a single cable that connects to the central computer, comparable to a hub-and-spoke model. This design significantly reduces wiring complexity, lowers weight, and enhances serviceability.

Another development to reduce wiring cost is increasing the voltage of power lines (e.g., 24 V or 48 V instead of 12 V). Assuming the powered devices are untouched and require the same electrical power (P = IV), doubling or quadrupling the voltage will halve or quarter the current in the wires respectively.

The current that runs through a wire is inversely proportional to its width/gauge. According to Ohm’s Law (I = V/R), if the current is decreased dramatically, then the wire can be built thinner, reducing both weight and cost.

The last technological development that leads to PoDL is the introduction of SPE. Compared to other modes of wiring (CAN or multi-twisted-pair Ethernet), SPE fills the niche for the needs of automotive communication.

>>Download the PDF of this article

SPE with 1000BASE-T1 protocol can transfer up to 1 Gb/s, which is 100X the data speed compared to CAN FD implementations, allowing for faster and smarter communication. This property and its weight compared to regular two- or four-twisted-pair Ethernet, enables SPE to efficiently transmit data while significantly conserving weight.

Overvoltage and Overcurrent Protection in PoDL

PoDL combines both power and data into one wire. It operates similar to power over Ethernet (PoE), except instead of using a four-twisted-pair Ethernet cable, a single twisted pair, or SPE, is used.

The power-sourcing equipment (PSE) side couples a DC power signal to a high-frequency, low-voltage data signal. On the powered device (PD) side, the DC and data signals are then isolated from each other. The DC voltage is then sent to a DC-DC converter to properly power any relevant subsystems.

Figure 2 features capacitors and inductors to produce a coupling decoupling network (CDN). The capacitor is used to remove any DC power from the data signal, and the inductor filters out any high-frequency signals from the power line.

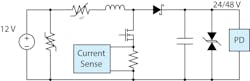

While SPE and PoDL efficiently transfer data and power, they must be protected and secured from any overvoltage or overcurrent events. SPE with PoDL is able to overcome this problem by separating protection into three parts. The primary section includes the protection of the PSE. The PSE typically incorporates a boost circuit to increase the voltage level from 12 V to 24 or 48 V. This is critical for downstream PDs because PSEs are at risk from overvoltage and overcurrent events.

To mitigate this, PSE circuits include metal-oxide varistors (MOVs) or multilayered varistors (MLVs) and transient-voltage-suppression (TVS) diodes for overvoltage protection. PPTC resettable fuses are utilized for overcurrent protection, and precision shunts for current monitoring. MOVs or MLVs are excellent at dealing with large overvoltage events. Typically, MOVs and MLVs are placed in parallel with voltage sources that can supply high currents such as a 12-V lead-acid battery. They’re economical and capable of handling several hundred amps in a compact size.

Like the MOV and MLV, a TVS diode is a reliable technology that has precision overvoltage clamping action. This device clamps excess voltage, ensuring voltage entering the SPE cable doesn’t exceed the expected value (either 24 or 48 V). The second protection measure uses polymer positive temperature coefficient (PPTC) resettable fuses for overcurrent and to mitigate overcurrent events from damaging cables, traces, or critical devices.

Current sensing plays an important role as well. For the boost converter to detect perturbations in the input or output power, the current-sense resistor, and its sensing circuitry, are constantly monitoring for overcurrent events. These components are implemented in the PSE boost converter (Fig. 3).

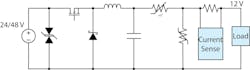

As discussed earlier, assuming the SPE cable is carrying higher voltage, the voltage must be stepped down for use by the PD or load. This is achieved by using a buck DC-DC converter. Like the PSE, the PD also requires proper protection from overvoltage or overcurrent events. Multiple devices accomplish this goal, such as current sensors, MOVs, TVS diodes, and PPTC resettable fuses (Fig. 4).

Current sensors are especially critical in systems with fluctuating voltage and current. Reliable current sensors are constructed using a voltage divider measured with a low-resistance shunt. MOVs perform like more robust TVS diodes, able to divert large voltages away from sensitive components. PPTC fuses are typically resettable, making them valuable in an automotive application where re-servicing may be limited due to active use. Since DC-DC converters operate at various voltage levels, each protection device must be rated accordingly.

The last protection measure to ensure safety from overvoltage and overcurrent incidents is to protect the SPE data line itself. As shown in Figure 5, transient blocking units (TBUs) and MOVs or MLVs are used to protect the data line of the SPE.

TBUs act similarly to resettable PPTC fuses and are preferred in the data line due to their high-speed reaction, operating in the nanoseconds. Being able to react to a surge the nanosecond it occurs ensures that delicate circuitry is protected while preserving as much data as possible.

Alongside the TBU devices, MLVs offer low-capacitance overvoltage protection from both electrostatic discharge (ESD) and surge for data lines. With the importance of signal integrity, low-capacitance devices such as MLVs are preferred for signal-line protection such as SPE. They also offer low-voltage clamping in small packaging.

Conclusion: PoDL, SPE, and Protection for Next-Gen Data Networks

The evolution of automotive data networks, exemplified by PoDL and SPE technology, marks a significant step toward creating more efficient and secure vehicular systems. By integrating power and data onto a single line, PoDL addresses the dual challenges of reducing vehicle weight and supporting the increasing data demands of modern sensors and subsystems.

Crucial to this advance is the implementation of robust protection mechanisms. Overvoltage and overcurrent safeguards, including TVS diodes, PPTC resettable fuses, MOVs, and TBUs help ensure network resilience against electrical surges. These protective measures not only protect power and data connections, but they also elevate the overall reliability and safety of the vehicle's electronic ecosystem.

>>Download the PDF of this article

About the Author

Jed Boyer

Power Applications Engineer, Bourns Inc.

Jed Boyer serves as a Power Applications Engineer at Bourns, with the responsibility to help design innovative circuit protection solutions that ensure reliability and safety. Boyer’s experience includes helping customers with component selection and collaborating on application-specific designs. He holds a BSEE from the University of Illinois at Urbana-Champaign.