Wireless BMS: Perils and Possibilities for Electric Vehicles

What you'll learn:

- What’s the difference between traditional BMS and wireless BMS?

- What are the most popular wBMS architecture types?

- Impact of wireless BMS on EV manufacturing and maintenance costs.

- How to integrate wireless BMS into battery architecture.

A battery-management system (BMS) is one of the key components of electric vehicles. It’s crucial for ensuring safety, longevity, and managing the performance of battery packs. The BMS controls the state of health and state of charge of the battery cells, thus optimizing their stability through cell balancing. It oversees such core parameters as cell voltage, current, and temperature to make sure everything is within safe limits.

Today, most automotive manufacturers are trying to decrease the resource intensity of their designs. While wired BMS has proven reliable over time, it heavily relies on copper wiring and electrical connectors, which can wear out over time. Locating and repairing these issues is usually very costly.

Such system imperfections of wired BMS design provoked the emergence of a wireless BMS. Transitioning to wireless BMS significantly simplifies the design of high-voltage batteries (800 V and higher) and improves their overall reliability and safety.

This article focuses on the differences between traditional and wireless BMS, comparing their strengths and weaknesses while exploring various wireless BMS architectures.

Wired BMS

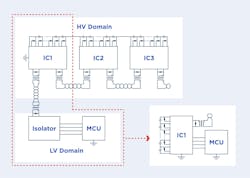

The architecture of a traditional wired setup consists of multiple analog front-end (AFE) chips. AFEs serve as intermediaries between BMS and battery cells, which are grouped into modules. Each module typically has from six to 24 cells.

The AFE chips monitor the cell’s temperature and voltage, as well as control cell balancing. They’re placed on a printed-circuit-board assembly (PCBA), which communicates with a BMS to manage the entire battery system’s functionality.

The wiring, leadframe, or flexible printed circuit (FPC) keep the module’s cell terminals connected to the PCBA. Such a design is replicated several times, creating a high-voltage battery pack.

For efficient communication between central BMS and several PCBAs, wire harnesses are used to connect them through an isolated communication bus. This approach makes it possible to control the performance of the entire battery pack in real-time. Figure 1 shows a close-up of the wired BMS architecture.

The wired BMS is a commercially proven technology. The wired connections make the data transmission less vulnerable to external interference and provide stable communication without the threat of cyberattacks. Despite the undeniable benefits of this setup, it also comes with some limitations, namely:

- It’s a time-consuming and costly manufacturing process. Assembling the battery pack with wires and components demands precision. Depending on the size of the battery, the complexity of the task varies.

- Wired BMS is hard to scale. Changing configuration may require more complex wiring setups, raising the cost and minimizing the general flexibility of the system’s design.

- There are risks of electrical breakdown and short circuits. To avoid this issue, isolation circuits must be implemented, which also adds to the overall cost of the battery pack.

Making the Switch to Wireless BMS

A wireless approach was created to address the drawbacks of wired BMS. Wireless BMS has a design similar to that of wired BMS. It also contains AFE chips to control, measure, and send key parameters from each battery cell within a module to PCBA.

However, instead of a wired communication bus, the connection between modules and the BMS host is established wirelessly through Bluetooth Low Energy (BLE), near-field communication (NFC), Zigbee, ultra-wideband (UWB), or proprietary wireless communication protocols. Also, the network’s wireless chipset is coupled with radio-frequency antennas designed to provide effective work in enclosed environments of the battery pack.

BLE, Zigbee, and UWB-Based wBMS

Among the most common wireless technologies used in wBMS development are BLE, Zigbee, and UWB. Both Bluetooth and Zigbee are low-power communication protocols, functioning at 2.4 GHz. However, BLE operates in a personal area network (PAN), which makes it a short-range technology, while Zigbee functions in a local area network (LAN), covering a larger area.

>>Download the PDF of this article, and checkout the TechXchange for similar articles and videos

What differentiates UWB from BLE and Zigbee is that it uses high-bandwidth pulses instead of modulated carrier frequencies. Such an approach offers better resistance to signal interference and fading, ensuring reliable data transmission. UWB BMS technology enables decoupling of mechanical and electrical development phases.

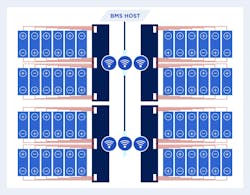

This solution allows for reduction of project timelines and costs. It also eliminates connectors and ensures that wiring between the cells provides a better energy density, extending vehicle range. UWB is a radio technology can be used at an incredibly low energy level for short-range, high-bandwidth communication over a large portion of the radio spectrum (Fig. 2).

UWB’s capabilities allow for accurate synchronization of measurements like current and voltage readings across battery packs’ subsystems well below the microsecond level. Another benefit of UWB-based BMS is the time-slotted scheduling approach.

That approach is possible due to static star network design (Fig. 3), where all UWB transceivers are synchronized, knowing when to send or receive data. As a result, the system can switch operating modes to save energy and eliminate issues related to frequency hopping or data collisions. The network design approach is also applicable to BLE and Zigbee radio technologies.

NFC-Based wBMS

Another wireless technology used for BMS is near-field communication. It provides chip-on-cell technology for incorporation in high-voltage lithium-ion batteries. Basically, a CMOS chip with embedded software transfers all of the parameters into each cell monitor and sends data of the individual cell via NFC technology.

A thin, low-voltage wire loop around the battery pack connects to the sensor to ensure quick and reliable data transfer, keeping a small physical separation. This is also done to provide electrical isolation for high-voltage batteries. Each chip has its own identifier, which is polled through an NFC connection by a radio manager, which controls the communication process and transmits data to the vehicle battery management unit.

V-Band Transceiver-Based wBMS

Integrating unlicensed 60-GHz RF millimeter-wave (mmWave) or V-Band into BMS offers significant opportunities for short-range contactless connectivity by enabling exceptionally high multi-gigabit data rates. It provides connector-free datalink solutions with unprecedented stability.

Most transceivers for the 60-GHz band offer a power-efficient wireless link with a high data rate (up to 10 Gb/s), making short-range (a few centimeters), point-to-point communication possible without relying on physical cables and connectors.

This compact, high-performance wireless link transceiver with a high data rate is a game-changer for short-range, point-to-point contactless communications, offering:

- Elimination of cables in industrial electronic systems exposed to mechanical stress due to flexing and bending.

- Exceptional efficiency, compact form factor, and innovative architecture for an optimized bill of materials.

- Replacement of expensive, hardened connectors in equipment operating in harsh conditions such as water, dust, salt, and vibration.

- The ability to ensure physical or electrical insulation while enabling seamless connections.

Figure 4 shows the possible architecture of wBMS used V-Band radio transmitters.

Difference Between Wired and Wireless BMS

Wireless communication in BMS provides several benefits over traditional designs. A wireless BMS eliminates the tedious manual assembly and testing required with a wired BMS — the only connection needed is usually to the power terminals.

Also, wireless communication minimizes the risks of short circuits, as there are minimal physical connections that can degrade over time. Minimization of these connectors makes the system more reliable.

Another big advantage of wireless battery-management systems is scalability. It enables manufacturers to use the same module design across other vehicle models.

In the traditional approach, battery cells are connected to the battery pack with cable harnesses. However, this wiring setup limits the number of battery cells that can be incorporated in the system. With a wBMS, it’s quite the opposite, as flexibility is gained in changing the number of battery cells based on needs.

Despite many attractive features, wBMS also has its flaws:

- Signal interference: The battery pack design can disrupt the wireless signal between cells, modules, and the BMS host.

- Security risks: Due to wireless communication, the system is prone to cybersecurity breaches.

- Complex initial setup: The BMS ASICs should be initially bound to a system.

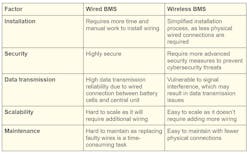

The table compares the differences between wired and wireless designs.

Impact of Wireless BMS on EV Manufacturing and Maintenance Cost

Regarding the cost of BMS, there's no obvious answer to what will be more cost-efficient for the specific case. When it comes to manufacturing, a wireless battery-management system could lower cost as it doesn't use much wiring and, therefore, requires less resources.

However, the wireless communication modules can be expensive in the initial development phase as they necessitate specialized experts, especially RF designers, who can work on the system's design. From a maintenance standpoint, wireless BMS offer benefits such as fewer wiring issues and reduced diagnostic labor, potentially reducing long-term maintenance costs.

Still, wireless modules and potential signal interference pose new maintenance challenges, as wireless component failures or communication issues can require costly specialized repairs and ongoing calibration. Overall, while the initial investment in a wireless BMS is higher, in the long run, the system's flexibility and scalability can reduce cost in both production and maintenance.

How to Integrate Wireless BMS into Battery Architecture

When integrating a wireless BMS into a battery architecture, it’s very important to follow the key recommendations. For instance, whether it’s a wired or wireless BMS, it must be designed to comply with the ISO 26262 standard for road vehicles. The highest level of safety, Automotive Safety Integrity Level D (ASIL D), requires the system to have safeguards in place to manage critical failures, including unexpected malfunctions and communication problems.

The RF environment inside an electric-vehicle battery comprises metal components, which can cause interference or signal blockage. Because the system transmits only a small amount of data every second, the data loss will not significantly reduce system performance. However, if left unresolved, such problems can jeopardize battery safety, leading to dangerous consequences like thermal runaway.

To avoid this risk, RF designers must carefully optimize the reliability of data transmission between transmitter and receiver. The packet error rate (PER) can provide guidance for designers. Ideally, the probability of successful transmission should be 99.999%, where the packet error rate is 10–7. This means that for every 10 million data packets sent, only one packet can fail.

To ensure the highest level of wBMS security, it’s essential to focus on the device and wireless network level. For example, data exchanged over the network must be protected by AES or other encryption methods; only trusted devices can access the network and communicate through mutual authentication. Also, the debug ports must be locked once the vehicle is deployed to avoid tampering.

Will EVs Fully Switch to Wireless BMS?

Since wireless BMS has only recently seen adoption in the automotive industry, vehicle manufacturers are still researching and testing wBMS.

For example, General Motors has incorporated a wireless Ultium BMS. The reason for the switch from wired communication was the expensive and unreliable design, with copper wires connected to the battery components. Instead, the company incorporated a wireless transmitter connected to each Ultium battery cell. With the implementation of wBMS, General Motors claims to have saved up to 90% of wiring and 15% of the volume in the battery pack.

Still, wBMS will not rapidly displace the traditional approach, as it remains the popular choice among vehicle manufacturers. Despite the advantages offered by wBMS, only a few companies are actively integrating wBMS into their vehicles. However, the market will soon offer a broader range of options, with wired and wireless BMS used for different use cases and vehicle types.

>>Download the PDF of this article, and checkout the TechXchange for similar articles and videos

About the Author

Roman Bykadorov

Embedded Engineer Tech Lead, Lemberg Solutions LLC

Roman Bykadorov brings over 23 years of experience in developing a wide range of system solutions for embedded electronics. With a strong background as a full-stack developer and deep expertise in embedded systems design, he specializes in both software and hardware development. Roman has successfully delivered projects across diverse industries, including heavy machinery, industrial electronics, industrial IoT, automotive ECU development, as well as smart-home technologies and consumer electronics.