Download this article in .PDF format.

Aerospace test applications run the gamut from electronic warfare (EW) to in-flight entertainment. Challenges extend from simulation, modeling, and data acquisition at the design and prototyping phases to manufacturing test and finally on to depot and flightline test. Equipment able to serve aerospace test applications extends from handheld instruments to complete systems comprising hardware and software. Key companies serve one or more aspects of aerospace test.

Vertical integration

MTS offers a range of PXI/PXIe instrumentation and switching products (GX Series) as well as GENASYS benchtop (TS700 Series), GENASYS semiconductor (TS900 Series), and GENASYS aerospace and satellite test systems (TS-321/TS-323).

According to Bob Stasonis, technical product specialist at Pickering Interfaces, “We do a little bit of everything. We have worked on functional test applications for many different avionics FRUs (field replaceable units) including FADEC (full authority digital electronic control) for jet engines, cockpit instrumentation, satellite testing, SDR (software defined radios), flightline systems test for the A-10, and even cable testing within an aircraft fuselage.”

Stasonis added, “Our extensive range of switching and simulation products are designed to work in many markets, aerospace being one of them. From a historical perspective, FADEC testing was the application that got Pickering into the HILS (hardware in the loop simulation) market. Today, we have the broadest range of FI (fault insertion) switch modules in the PXI formfactor.”

Stasonis continued, “As FRUs get more complex, higher-density matrix switching becomes more critical for managing more digital and analog I/O. Microwave switching up to 67 GHz will become the norm as even defense contractors are looking to 5G communication for secure data transmission and potentially robotic surgery near the battlefront!”1 He added that testing DAQ systems with thermocouples, RTDs, and other input types calls for compact automated simulation such as Pickering offers.

COTS for HIL

Eccles, Murphy, and Blume said the company offers a range of closed-loop/hardware-in-the-loop (HIL) test platforms that are customer-configured for specific application spaces, including FADECs/EECs, flight-control systems, and environmental controls. “Each platform contains a basic complement of simulation types which may be customized for the customer’s control system requirements,” they said. “The Bloomy Simulation Reference System provides a launching point for other closed-loop/HIL applications. Customers’ test engineers may use these platforms and systems to jump start their test development cycles, thereby shortening schedules, reducing costs, and freeing resources to focus on the differentiating technologies which make their products unique in the marketplace.”

They continued, “Bloomy provides several industry-first modules and interconnection solutions for the National Instruments (NI) Switch, Load, and Signal Conditioning (SLSC) and compactRIO platforms, which our customers can use to speed test-system development using COTS components. These include an 8-channel high-precision thermocouple simulation module, an 8-channel VDT/resolver simulation module, an 8-channel load module, a ThroughPoint interface panel, and a MIL-STD-1553B avionics bus communications module.”

Tactical communications

Recent ATS solutions include the new ATS-3100 VRS (VST-based Radio Solution) for tactical communications test of airborne radios, the Freedom R8100 for Avionics Ramp Testing, and single-rack Link-16 solution that can serve both manufacturing and maintenance needs. “In this way, we optimize our operational scenario (that is, size, weight, and power) for the depot setting so maintenance can deploy closer to the military assets they serve,” Vondran said. “Our engineer-to-engineer collaborative culture is key for developing a reliable and sustainable platform.”

EW hardware and software

Keysight’s products, and the support of open interfaces and architecture, offer customers EW threat-simulation solutions ranging from benchtop testing to full-scale threat simulation. Scalability, coupled with the ability to reconfigure the system to utilize RF test assets effectively, delivers a modernized EW test and evaluation solution.

“Keysight understands that our customers need solutions that can maintain pace with the accelerating evolution of the EW threat environment,” said Greg Patschke, general manager of Keysight’s Information Warfare Group, in a press release. “We will continue to partner with our customers to create and deliver rapidly adaptable solutions that help them advance their labs to the next level of testing.”

The open architecture of Keysight’s EW threat simulation solutions enables customers to create scenarios with a variety of software tools, often utilizing a customer’s existing threat databases. Customers can also choose the software tool that best fits their EW test needs for pre-scripted or dynamic real-time threat generation, or both.

Instruments and data acquisition

According to David J. Rodgers, senior program manager for SAN, Ethernet, and Fibre Channel technologies at Teledyne LeCroy, “Our products will be used for evaluation and verification of wired, fibre-interconnect communications, focused on, but not limited to, ensuring fly-by-wire messaging is accurate, timely, and complete.” Specific products include the SierraNet M168 Fibre Channel and Ethernet test platform, which includes data capture, analysis, and manipulation routines. “SierraNet enables test/validation engineers to observe and modify the physical interface and associated data frames used in mission-critical avionics and communications systems,” Rodgers said.

Picotest focuses on power integrity, including low-power distribution network testing and PDN impedance testing, according to Charles Hymowitz, the company’s VP of marketing and sales. “This applies to every application area,” he said, adding that the company also addresses cable, connector, and PCB coupon testing.

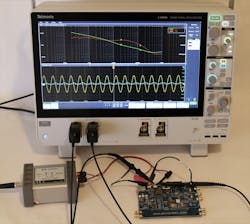

Specific products include vector network analyzers, such as the 1-Hz to 50-MHz OMICRON LAB Bode 100 VNA; probes and impedance-testing accessories, such as 1-port and 2-port PDN probes, ground-loop breakers, active splitters, and PDN cables; power-supply testing accessories for step load testing, Bode-plot stability testing, and PSRR/PSMR testing; new oscilloscope support for impedance, Bode, and PSRR testing; and a “pocket” TDR for cable, connector, and PCB coupon testing

“We are focused on supporting power-integrity testing,” Hymowitz emphasized. “We are the only company with power-integrity test accessories that support VNAs and oscilloscopes from all instrument companies. Power-integrity problems cross applications, disciplines, and customer bases. Since voltage levels are falling, power integrity is becoming a bigger and bigger problem for everyone.”

CTT supplies customers worldwide with power amplifiers (including GaN narrow-band power amplifiers), frequency converters, frequency multipliers, transmitters, transceivers, and receivers from 10 MHz to 100 GHz. “Amplifiers can be supplied in connectorized assemblies or rack-mount configurations,” a company marketing representative said. “Setting CTT apart from other manufacturers is our unique spectrum of Custom Engineered Options (CEOs) that can be readily integrated within most package formats.” Typical options include DC/DC converters, AC/DC converters, TTL control, samplers, couplers and detectors, heat exchangers (conduction, convection, forced air or liquid), and waveguide inputs/outputs.

“Since 1981, CTT has been designing and delivering microwave amplifiers and assemblies for use in test and measurement areas including EW, electronic countermeasures (ECM), electronic support measures (ESM), and radar systems including surface-aperture radar (SAR),” said the representative. “The products find use in missiles, jammers, UAVs, seekers, decoys, data links, simulators, and commercial communications systems.”

In related news, Anritsu recently added real-time spectrum-analysis (RTSA) tools for its Field Master Pro MS2090A handheld spectrum analyzer, which can measure the amplitude of a single spectrum event as short as 2 µs and detect a single event as minimal as 5 ns. Its ability to more accurately detect intermittent interfering signals provides distinct advantages in a number of aerospace/defense, satellite-system, and radar applications, the company said.2 The Field Master Pro MS2090A RTSA provides a continuous stream of FFT measurements over a 110-MHz analysis bandwidth, which enables a 2.055-µs probability of intercept (POI).

In addition, Rohde & Schwarz recently expanded the available frequency options for its analog R&S SMA100B RF and microwave signal generator, offering now a contiguous frequency range from 8 kHz up to 72 GHz. “The instrument provides the purest output signals while maintaining the highest output power level, far outpacing the competitive solutions,” said Simon Ache, director of signal generation product management at Rohde & Schwarz, as quoted in a recent report on signal generators.3 “It is capable of handling the most demanding component, module, and system T&M tasks in the RF semiconductor, wireless communications, and aerospace and defense industries.”

Highland Technology recently introduced a new member of its aerospace simulation suite—the P348 midfrequency sinewave dual-channel quadrature modulator instrument with C-coupled baseband I and Q inputs. It is suitable for a range of transducer simulation applications that make use of eddy-current, inductive, and capacitive sensors. It is also suitable for classic RF modulation tasks. The carrier frequency can range from 500 kHz to 20 MHz.4

From components to I/O boards

Samtec focuses on radar, including long-range discrimination radar (LRDR) and phased-array radar; communications (Manpack radio); and navigation, according to Brian Niehoff, technical marketing engineer at the company. Specific products include modified COTS solutions; Edge Rate rugged, high-speed connector strips; Razor Beam fine-pitch self-mating connectors; Q-Strip high-speed mezzanine connectors; high-speed cable assemblies; and the FireFly Micro Flyover System.

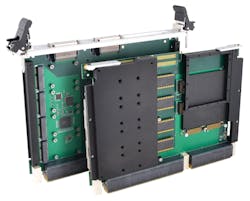

Russell Nieves, vice president of sales at Acromag, said his company focuses on radar, avionics, and flightline test systems, offering embedded computer technologies, including user-configurable FPGA I/O modules. “We design and manufacture a diverse portfolio of COTS products that customers can use right from the start,” he said. “They are made in the USA (Michigan), and we have been doing this for over 60 years.” Nieves continued. “We see customers continually wanting to upgrade speed and capacity for things like data acquisition and video imaging. We try to develop new products in a timely fashion to meet these requirements.”

Model-based design

MathWorks provides computing environments for engineers to analyze, simulate, implement, and verify their complex logic designs such as radar schedulers, flight-control algorithms, or SDR transceivers, according to Albert Ramirez Perez, aerospace industry marketing manager at the company. “Model-based design is used by engineers to identify the optimal detailed design,” he said. “Using desktop simulation, failures can be identified earlier in the process, avoiding costly project delays and increased workloads.”

Ramirez Perez continued, “Engineers use MATLAB and Simulink families because the tools provide a wide range of the most-commonly used algorithms and techniques for designing complex logic using numerical computations, not only by executing individual test cases, but, more importantly, allowing them to build a set of test cases that covers the required specification. Model-based design allows engineers to focus most of their efforts on maturing and optimizing the specifications, minimizing the requirements and design errors and maximizing the test coverage in a common desktop environment, so later phases can be streamlined. Finally, engineers are able to automate the implementation, easily use formal methods for verification, and perform functional testing where the full set of evidences are automated.”

MathWorks offers textual and graphical desktop design environments that engineers use in traditional V-cycle and agile development, Ramirez Perez said. “On top of the base platforms MATLAB for math and programming and Simulink for simulation and model-based design, a set of toolboxes for specific technologies is available providing predefined algorithms. Engineers can find analysis, design, and optimization products in the main industries such automotive, aerospace, or semiconductors with algorithms relating to areas including artificial intelligence, 5G, automated driving, and radar and phased array, among others. Model-based design horizontal products cover engineering needs in most of the V-cycle phases: systems, software, testing, and integration.”

He added that the just-released System Composer for systems engineering and architecture complements mature products for requirements validation and coverage, software automatic code generation (C, C++, HDL, PLC, or CUDA), formal methods and static analysis, and model-in-the-loop, software-in-the-loop, and hardware-in-the-loop functional verification for requirement-based testing.

“For complex environments and projects, MathWorks offers training and consulting services to guide teams to apply best practices in development workflows,” he said.

MIL vs. commercial

Many of the products described in this article are suitable for both military and commercial aerospace test. According to Semancik at MTS, “There are many similarities between military and commercial aerospace customers—for example, the need for the manufacturer to implement and maintain quality-management systems such as AS9100D and AS5553.

Semancik continued, “Test result(s) traceability is also important; therefore, developing test systems with common user interfaces and report generation capabilities resonates with both customer groups.”

“The requirements of military and commercial aerospace customers are very similar, with the overriding trend toward increasing the use of commercial, off-the-shelf (COTS) testing equipment in order to reduce cost and lead times,” said Eccles, Murphy, and Blume at Bloomy Controls.

“All customers are looking for optimal solutions that address both their unique requirements and the constraints they are dealing with,” according to KRYTAR marketing. “For military applications, products are designed and constructed to meet MIL-SPEC requirements.”

Stasonis at Pickering commented, “Our military and commercial aerospace customers share the common traits of demanding specifications, reliability, and product availability for a long time.”

However, Stasonis continued, “If there is a difference between them, it is probably the military’s need for secrecy. In some cases, we are not allowed to know what we will be testing. The commercial industry is much more open with us. Military presents a whole different dimension of test—for example, the military is looking at electronic warfare and different communication protocols for security and secrecy. Whereas, commercial applications may be more concerned with seatback entertainment and taking credit card info at 35,000 feet. So, it can be different levels of complexity.”

Eccles, Murphy, and Blume also cited a divergence between military and commercial customers. “One obvious difference is security; however, most of our aerospace customers have commercial as well as military contracts, and therefore Bloomy is ITAR-registered and has many security procedures in place. Also, military-aerospace applications are increasingly using FAA certification processes where previously they did not—even for mission-related systems. There is also a greater variety of military airborne systems than commercial systems in service, and military systems tend to be reconfigured for different mission profiles, with new sensor hardware, weapons systems, and software requiring integration. Thus, a military aerospace platform tends to have a greater requirement for test/validation throughout its lifecycle.”

Ramirez Perez at MathWorks also commented on differences. “The first difference is the severity of the process and the standards that programs need to comply with, which is due to the impact of a potential failure in the system measured,” he said. “Engineers need to design their systems considering worst-case scenarios. A failure in commercial aerospace can lead to injures or casualties to the civilian population whereas a failure in a military application is directly related to the capability to accomplish a mission with mainly tactical or economic impacts for the operator.”

Ramirez Perez continued, “Secondly, commercial aviation has been driven by COTS environments, which reduce the cost by using enough reliable, well proved components. COTS systems ease the verification and integration at the final platforms but constrains the flexibility of engineers to achieve new designs. On the other side, military developments have given a higher priority to customizations, security, and isolation through specific implementations, which offers more freedom to engineers on their designs, but increases the complexity of the testing and verification solutions.”

MIL/aero OEMs are all looking for shorter time to market and easy-to-use solutions,” said Niehoff of Samtec. “That is where Samtec is filling the need with COTS items.”

Synergy

“Both commercial and military/aerospace customers require tools that are precise and adhere to the specifications for which the instrument(s) are designed,” said Rodgers at Teledyne LeCroy. “A key difference in military applications is the nature of the systems communications and components therein; there are more ‘mission-critical’ concerns and functions in a military airframe.”

“Numerous components in all microwave systems have continuously evolved and are now being optimized for specific applications,” according to CTT marketing. “Both military and commercial configurations can benefit from improvements in increased sensitivity, reduced size and weight, higher efficiency, reduced cost, and increased system power efficiency. Improvements in these areas can spring from either the system designer or from breakthroughs at the component level.”

Aerospace test trends

Several trends point to the future of aerospace test. “Aerospace programs are leveraging the cost and technology benefits of the commercial marketplace,” said Rodgers at Teledyne LeCroy. “This trend assists the aerospace market in providing an increase in product-development options at reduced costs to deploy. However, the aerospace industry, by nature of the products and services they supply and support, needs to ensure the general market products and designs can withstand the scrutiny and rigors of the level necessary to be used in aerospace applications. Test and measurement tools and practices must be maintained at the highest level possible in support of the aerospace requirements.”

“Along with emerging technologies like 5G, artificial intelligence (AI), and quantum computing, there will be an increase in the number of connected devices enabling an entirely new paradigm of connectivity and capability—which means that customers will require higher-performance and frequency with lower latency and wider bands,” according to KRYTAR marketing.

“Customers want to be able to stream real-time and record,” commented Nguyen at DTS. “SLICE6 Air supports both real-time streaming that’s viewable in industry-standard and nonproprietary data formats, as well as dual onboard recording to 16-GB nonvolatile memory.”

CTT marketing sees a range of applications—narrowband, wideband, or ultrawideband (microwave and mmWave)— operating in pulsed or CW mode, for new multifunctioned systems that effectively conserve weight, space, and power consumption.

“COTS buy-in is becoming more and more accepted,” said Niehoff at Samtec. “Samtec’s SET capabilities strengthen customer confidence in using a COTS product in their application.”

“The advances in AI and machine learning will likely mean more HILS applications to test for all possible circumstances, whether it is hardware, firmware, or software testing,” said Stasonis at Pickering. “We are also seeing a drive for smaller test systems in order to more easily bring support to the battlefront.”

“In general, the trends in the aerospace industry are slow in adoption (compared to something trendy like 5G),” according to Vondran at Astronics Test Systems, “Even so, the transparent, collaborative, and methodical process towards modernization seems to be moving toward a faster cadence. This agility combined with trusted relationships is what will accelerate the future of aerospace test into reality.”

Many of the spokespersons quoted in this article have elaborated on the points raised here and have weighed in on additional challenges and trends in aerospace test. A future article will provide more on the topic.

REFERENCES

1. Underwood, Kimberly, “5G for Warfighters,” Signal, AFCEA, June 1, 2019.

2. “Anritsu adds RTSA to Field Master Pro,” EE-Evaluation Engineering Online, Sept. 17, 2019.

3. “New technology demands, multifunctionality make signal generators more integral to testing than ever,” EE-Evaluation Engineering, November 2019, p. 6.

4. “Highland Technology debuts dual-channel quadrature modulator,” EE-Evaluation Engineering Online, Nov. 29, 2019.

For more information:

About the Author

Rick Nelson

Contributing Editor

Rick is currently Contributing Technical Editor. He was Executive Editor for EE in 2011-2018. Previously he served on several publications, including EDN and Vision Systems Design, and has received awards for signed editorials from the American Society of Business Publication Editors. He began as a design engineer at General Electric and Litton Industries and earned a BSEE degree from Penn State.