This file type includes high resolution graphics and schematics when applicable.

I remember when single-sided printed circuit boards (PCBs) with wires dominated many markets—like whitegoods—because it was possible to keep costs down. This is still done in some instances, but these days, multilayer PCBs are the norm. While these handle the fastest high-speed serial interfaces, the move to 56 Gbit/s SerDes (Serializer/Deserializer) may give PCB designers a run for their money, owing to the difficulty of handling the high-speed signals on large PCBs. Issues also arise when moving from board to board, including connector design challenges.

One alternative is to bypass the PCB and use wires to connect point A to point B. This is sometimes done for convenience or to simplify PCB design, but in the future it may be required to handle high-speed applications. One mid-board wiring solution is TE Connectivity’s Sliver system (Fig. 1). The current incarnation supports 12, 25, and 56 Gbit/s communication links that are sufficient for today’s high-speed serial standards like PCI Express, Ethernet, and InfiniBand.

The 56 Gbit/s SerDes is only being used in research and evaluation at this point, but it is likely that ultraminiature twinax will be the way to connect high-speed signals across a board or between boards.

Sliver, with high density 0.6-mm contact pitch, is already used for existing high-speed serial connections. The connection is much more efficient than a pair of PCB traces, and routing is often easier. This can also allow the designer to use less-expensive materials or fewer layers, since the high-speed connections bypass the PCB. Of course, this isn’t something that would be done with all signals, but it is usually sufficient to route one or two bus connections in many systems.

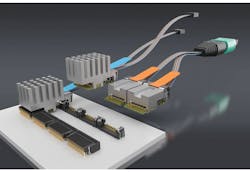

Sometime optical connections may be more appropriate. Samtec’s FireFly system combines optical transceivers with the connectors at each end (Fig. 2). The connectors also incorporate a heatsink to cool the transceivers.

The optical approach is more expensive because of much more complicated active connectors at each end. On the other hand, there are advantages to using fiber connections from reduced crosstalk and more robust EMI support to the ability to utilize longer fiber connections than is possible with copper solutions.

The Consortium for On-board Optics (COBO) is working on standardizing the optical mid-board approach that is currently dominated by vendor-specific implementations.

These connector and cabling systems provide designers with alternatives to conventional PCB designs. Optical may eventually be the wave of the future, but copper is definitely solving high-speed connection problems today.

This file type includes high resolution graphics and schematics when applicable.

About the Author

William Wong Blog

Senior Content Director

Bill's latest articles are listed on this author page, William G. Wong.

Bill Wong covers Digital, Embedded, Systems and Software topics at Electronic Design. He writes a number of columns, including Lab Bench and alt.embedded, plus Bill's Workbench hands-on column. Bill is a Georgia Tech alumni with a B.S in Electrical Engineering and a master's degree in computer science for Rutgers, The State University of New Jersey.

He has written a dozen books and was the first Director of PC Labs at PC Magazine. He has worked in the computer and publication industry for almost 40 years and has been with Electronic Design since 2000. He helps run the Mercer Science and Engineering Fair in Mercer County, NJ.

- Check out more articles by Bill Wong on Electronic Design

- Bill Wong on Facebook

- @AltEmbedded on Twitter