LED Lighting Management IC Improves Power Factor and Efficiency

There is great sensitivity to operating costs when dealing with high-powered commercial lighting. In these applications, there is increased emphasis on energy efficiency and ac line power factor because these parameters impact operating expenses. The electric utility penalizes the user with additional charges if the power factor and efficiency are outside their allowed limits. Plus, the lighting system must exhibit high reliability or the user's operating maintenance cost might be excessive. Therefore, the solution is to use of a lighting management system whose power factor is 0.90 or higher, whose system efficiency is at least 80%, and whose failure rate is measured in thousands of hours.

To understand the requirements for lighting power management, we have to investigate its present state-of-the art. Commercial outdoor lighting has featured incandescent types for years. In addition, HID (high intensity), halogen and fluorescent lamps have also been employed for the same purpose. Today, a better solution is use of high brightness, high power (HB/HP) LEDs that produce more lumens/watt than other lighting sources. This capability has allowed HB/HP LEDs to be adopted in general illumination applications, such as light fixtures and street lamps.

Advantages of HB/HP LEDs include:

- Typically 50,000 hours operating life

- Better reliability and durability than incandescent, HID, and halogen lamps

- Easier to control and dim than their lighting predecessors

- Reduced lumen depreciation over time

- Normally DC driven

- Driven by constant current

IC SOLUTION

Meeting the needs for HB/HP LED lighting management is the IRS2548D, a fully integrated, fully protected 600V LED control IC. The IRS2548D provides an integrated solution for LED power supplies that simplifies design and reduces overall system cost, while providing significant energy savings. This switch-mode power supply (SMPS) control IC is intended for energy efficient applications for HB/HP LED illumination for street lighting, stadium lighting and theatrical lighting. The IC can operate over a 90 to 305 Vac range.

The IRS2548D combines power factor correction and half-bridge driver in a single IC, as shown in the simplified diagram in Fig. 1. It offers over 88 percent efficiency for a 40 V/1.3 A HBLED (High-Brightness LED) load. This is a higher efficiency than a flyback converter operating at above 60 W.

The IC features a programmable minimum run frequency and adjustable oscillator frequency that can be driven by an opto isolator or other feedback circuit in a feedback loop for frequency modulation in resonant systems. The IC also includes PFC over-voltage and over-current protection, half bridge over current protection and a logic level enable input that can be used for PWM dimming in LED drivers or general burst mode operation.

The IC achieves PWM dimming down to less than 2 percent light output and offers protection features that include programmable PFC and half-bridge over-current protection, latch immunity, and ESD protection. The IRS2548D also includes variable frequency oscillator, fixed internal 1.6µs deadtime, internal bootstrap MOSFET, internal 15.6V zener clamp diode on Vcc, and micropower startup (250µA). The external resistor at FMIN sets the run frequency.

POWER FACTOR

High power factor is required for most LED drivers rated at more than a few watts. The driver must appear as a resistive load to the ac input line. The degree to which the circuit matches a purely resistive load is determined by the phase difference between its input voltage and input current. The overall power factor is the ratio between real and apparent power. A power factor of 1.0 corresponds to zero phase difference and a THD of 0% represents a pure sinusoidal current waveform. The IRS2548D includes an active power factor correction (PFC) circuit that provides a high power factor and low THD.

PFC BOOST CONVERTER

The control method implemented in the IRS2548D employs a PFC Boost converter (Fig. 1) running in critical-conduction mode, the boundary between continuous and discontinuous mode. During the off period of each switching cycle of the PFC MOSFET (MPFC) the circuit waits until the inductor current falls to zero before turning the PFC MOSFET on again. The PFC MOSFET is turned on and off at a much higher frequency (>10KHz) than the line input frequency (50 to 60Hz).

A fixed on-time of MPFC (Fig. 1) over an entire cycle of the line input voltage produces a peak inductor current that naturally follows the sinusoidal shape of the line input voltage. The smoothed averaged line input current is in phase with the line input voltage for high power factor. There is some harmonic distortion left, but it is mostly due to crossover distortion of the line current near the zero-crossings of the line input voltage. An additional on-time modulation circuit included in the PFC control achieves lower harmonics that comply with international standards such as EN61000-3-2 class C and general market requirements.

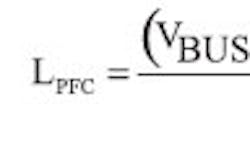

The value of the PFC inductor, L1, is:

Where:

VBUS = DC Bus voltage

VACMIN = Minimum AC input voltage

η = PFC efficiency (typically 0.95)

fMIN = Minimum PFC switching frequency at minimum AC input voltage

POUT = System output power

Peak inductor current, iPK, is:

The PFC inductor must not saturate at iPK over the specified system operating temperature range. Proper core sizing and air-gapping should be considered in the inductor design.

Where the internal threshold is 1.25V for the overcurrent limit, the PFC overcurrent resistor, ROC, is:

HALF-BRIDGE

As shown in Fig. 1, two external power MOSFETs and an output transformer make up the half-bridge circuit. External resistor R CS programs the maximum current in the half-bridge circuit. This resistor establishes an internal threshold of 1.25V and determines the overcurrent limit of the half-bridge. The value of RCS in ohms is:

Where:

IMAX = Maximum amperes

The Half-bridge output transformer drives a full wave rectifier, then is filtered and regulated to provide a dc constant current source for the LED load. The LED current is sensed and a voltage is fed back to the IRS2548D to maintain the constant current source at is prescribed level.

EVALUATION UNIT

To show the benefits of the IRS2548D LED control IC, a lighting management subsystem based on the device is available as an evaluation and demonstration unit, as shown in Fig. 2. Table 1 gives the results for the IRS2548D, when tested driving 32 Samsung HPLED packs with a total power rating of 55W. It operates from 90 to 305 VAC and is dimmable with a 1 to 10 VDC input.